Intelligent control system of double-line accurate seeding of wheat

An intelligent control system, precision seeding technology, applied in general control system, control/regulation system, program control, etc., can solve problems such as insufficient adjustment accuracy, troublesome adjustment of seeding amount, and inability to match the speed of seeding with the advancing speed of the unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

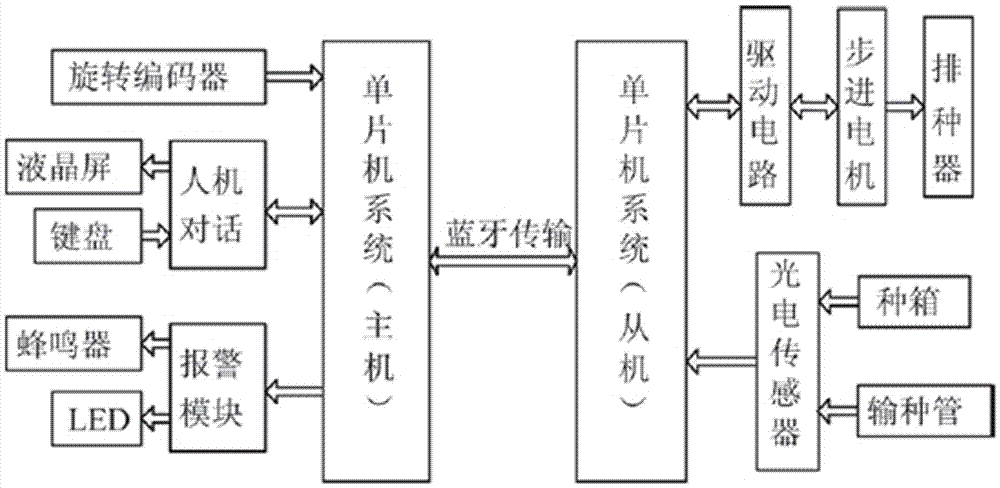

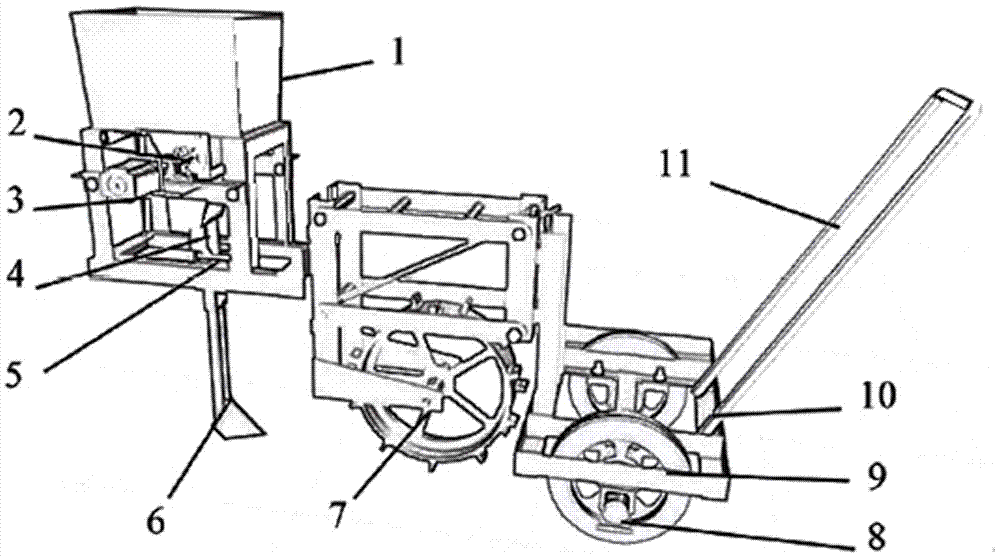

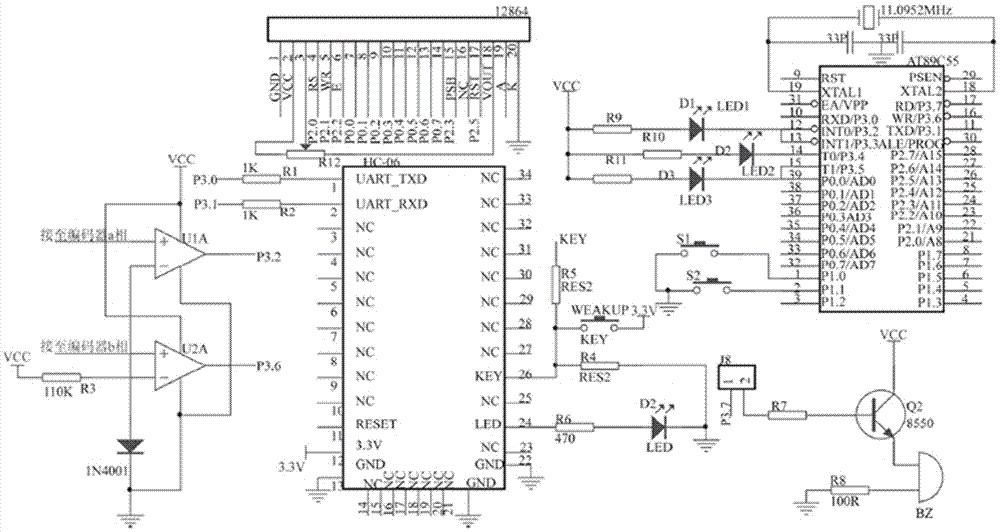

[0020] Such as figure 1 As shown, the wheat two-line precision sowing intelligent control system is composed of two parts: the host system and the slave system. Sowing, monitoring of sowing status and faults, etc.; two control units realize wireless transmission of relevant data through Bluetooth. The intelligent control precision seeder uses independent buttons to set the seeding parameters (including seed spacing and seeding amount); the rotary encoder is used to measure the forward speed of the seeder. After the speed measurement signal is sent to the host through the conditioning circuit and received and processed, the host then sends the parameter information such as the current vehicle speed and the set broadcast volume (grain distance) to the slave through the Bluetooth wireless transceiver module, and the slave performs comprehensive calculations to obtain At this time, the proper rotational speed of the stepping motor is used to control the rotational speed of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com