Intensive type hydraulic axial mobile two-phase variable valve driving system and control method thereof

A technology of axial movement and drive system, applied in the direction of engine control, engine components, machine/engine, etc., can solve the problem that the valve opening and closing timing and stroke cannot be adjusted independently, the valve operation process cannot be realized, the fuel supply and electromagnetic To solve problems such as too many valves, to achieve the effect of speeding up the practical process, simplifying the system structure and control method, and simplifying the vehicle modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

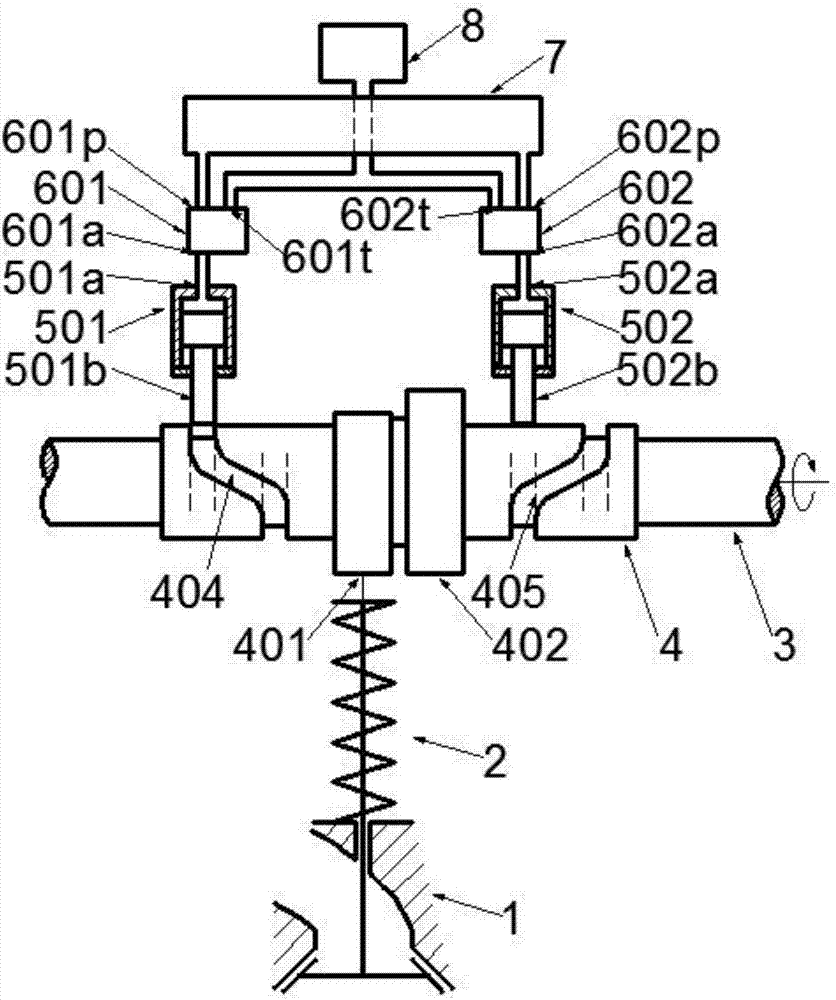

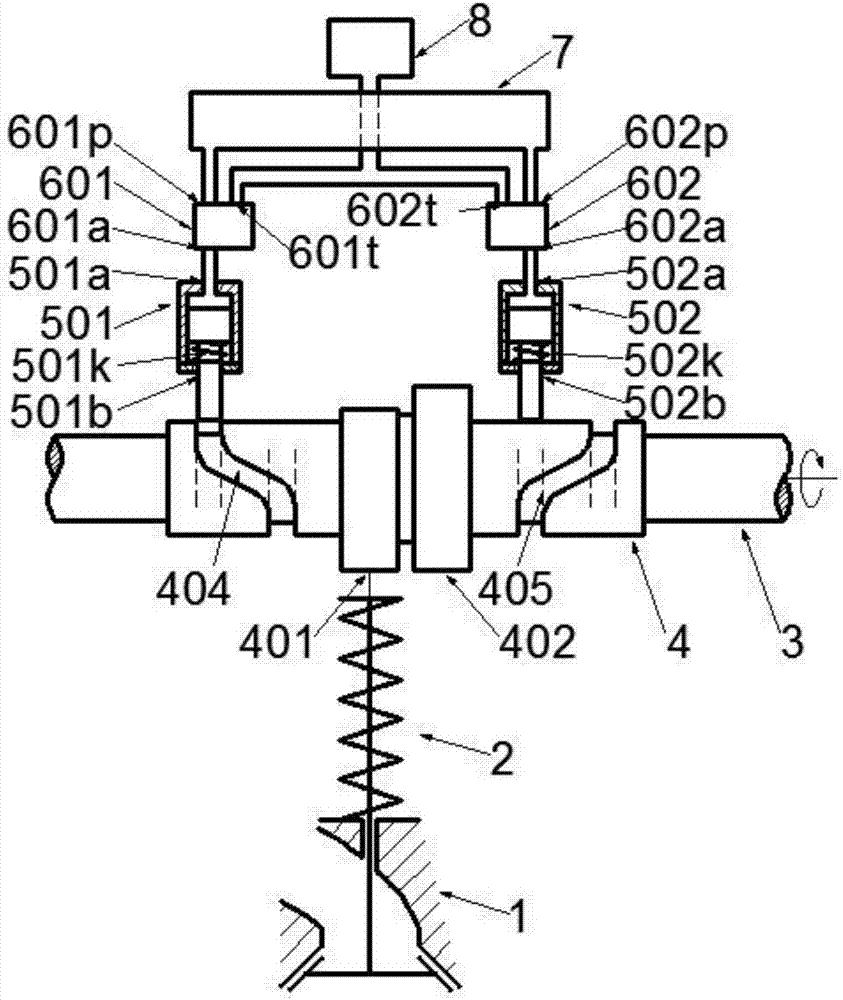

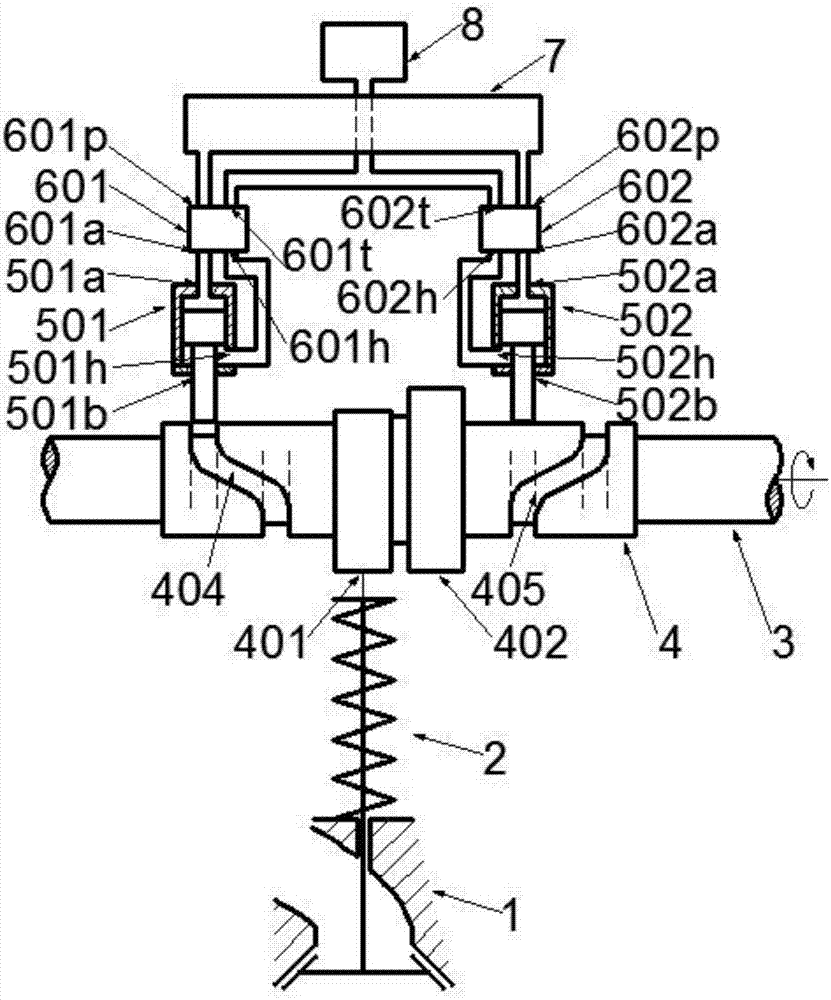

[0039] The invention relates to an intensive hydraulic axially moving two-stage variable valve drive system and a control method thereof. The intensive hydraulic axially moving two-stage variable valve drive system and its control method include a valve drive mechanism 2 . It also includes a camshaft 3, a camshaft sleeve 4, an actuator, a control mechanism, a high pressure source 7, and a low pressure source 8. A first switch slot 404 and a second switch slot 405 are provided on the camshaft sleeve 4 . A first cam 401 and a second cam 402 are also arranged on the camshaft sleeve 4 . The first cam 401 or the second cam 402 drives the valve driving mechanism 2 to move directly or through a transmission mechanism. The camshaft sleeve 4 moves axially along the camshaft 3 . The actuator adopts a reciprocating piston structure, including a first actuator 501 and a second actuator 502 . figure 1 It is a schematic diagram of an intensive hydraulic axially movable two-stage variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com