Isothermal casting wax pneumatic extrusion device

An extrusion device and pneumatic technology, applied in the direction of casting and molding equipment, can solve the problems of small contact area, high maintenance cost, low quality of wax mold, etc., achieve the effect of simple structure of the device, uniform and continuous heating, and improve the quality of wax mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

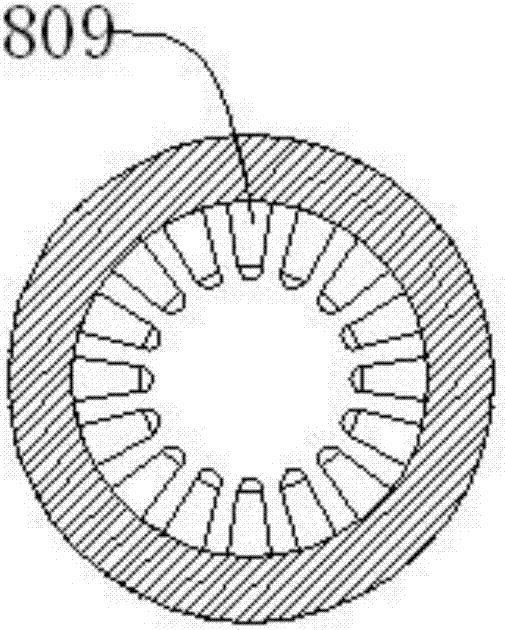

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a wax pneumatic extrusion device for soaking casting, including a base 1, a barrel 2, an upper cover 3, an air inlet pipe 4, a guide rod 5, a piston 6, a lifting cylinder 7, a heating mechanism 8, a discharge Tube 9, cooling jacket 10, controller 11, the barrel 2 is located at the upper end of the base 1, the barrel 2 is threadedly connected with the base 1, the upper cover 3 is located at the upper end of the barrel 2, and the upper The cover 3 is connected to the barrel 2 with gaps, the air intake pipe 4 is located at the upper end of the upper cover 3, the air intake pipe 4 is threadedly connected with the upper cover 3, the guide rod 5 runs through the upper cover 3, and the guide rod 5 is connected with the upper cover 3 with a gap, the piston 6 is located at the lower end of the guide rod 5 and inside the barrel 2, the piston 6 is threaded with the guide rod 5 and connected with the barrel 2 with a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com