Device for heating to stop corrosion and application method of device

A flame-retardant cotton and temperature-controlled switch technology, which is applied to coupling devices, parts of connecting devices, heating elements, etc., can solve problems such as poor contact between memory sticks and slots, easy condensation of water droplets on metal, and impact on service life. Achieve the effect of not easy chemical reaction, high efficacy, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

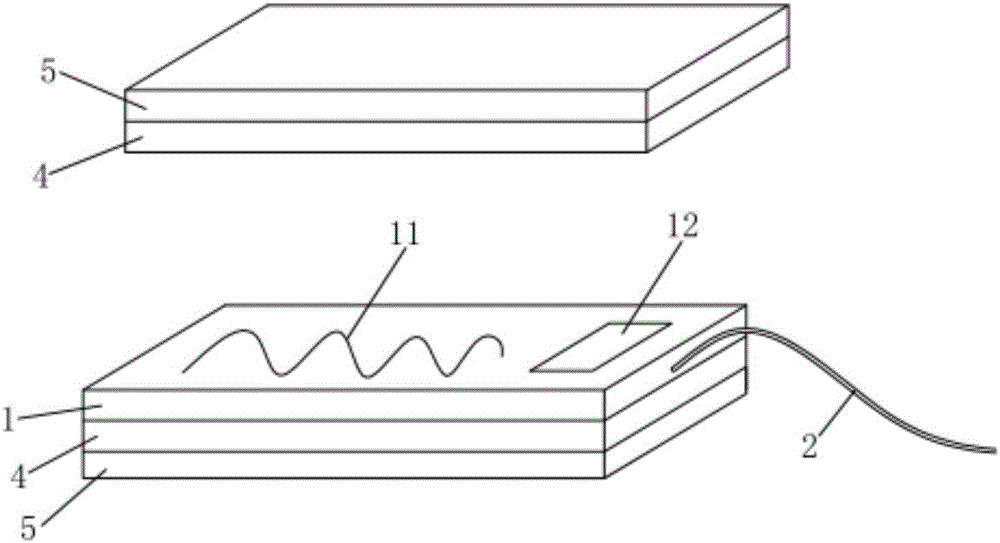

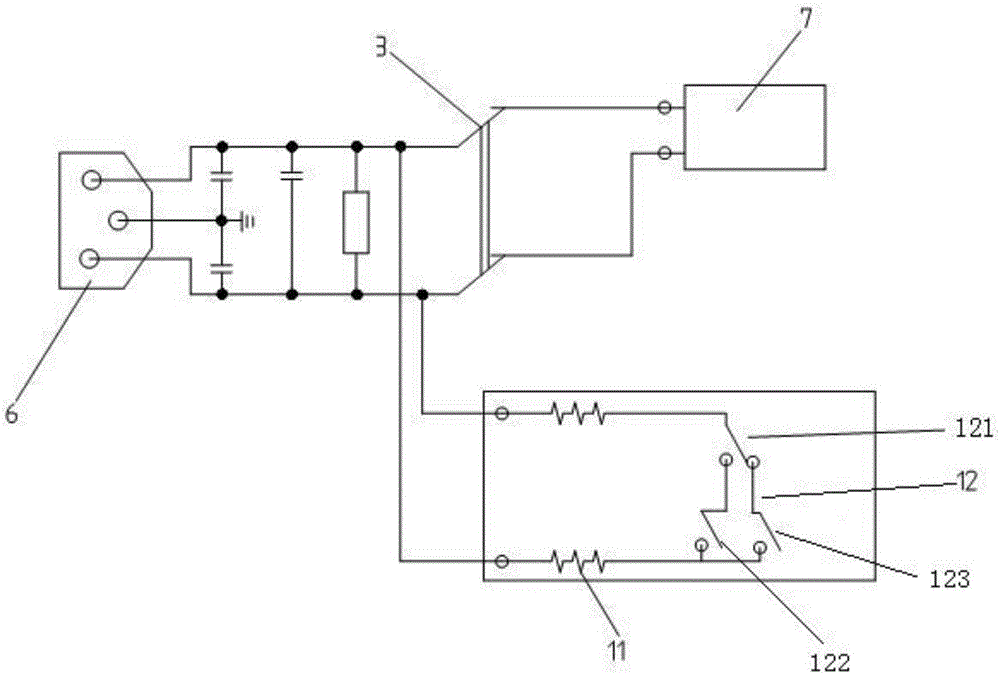

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0022] The invention is a device for preventing corrosion by heating. The parts to be protected, such as cast iron guide rails of precision machine tools, precision rails of mechanisms, etc., or daily household appliances, can be in the working state or in the non-working state, because when the parts Or when the electrical appliance is in a non-working state, it does not generate heat and is easy to accumulate water droplets, and even if some parts or electrical appliances are used normally, due to the low temperature, the metal is easy to condense water droplets, thereby causing chemical corrosion reactions; the use of the present invention The method is to install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com