Method of driving vibration actuator with enhanced sliding efficiency, vibration drive device, and mechanical apparatus

A vibration actuator and vibration drive technology, used in the field of mechanical equipment and driving vibration actuators, can solve the problems of small degrees of freedom in mechanical design of vibration actuators, and achieve the goal of improving sliding efficiency, reducing restrictions, and improving durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will now be described in detail with reference to the accompanying drawings showing embodiments of the invention.

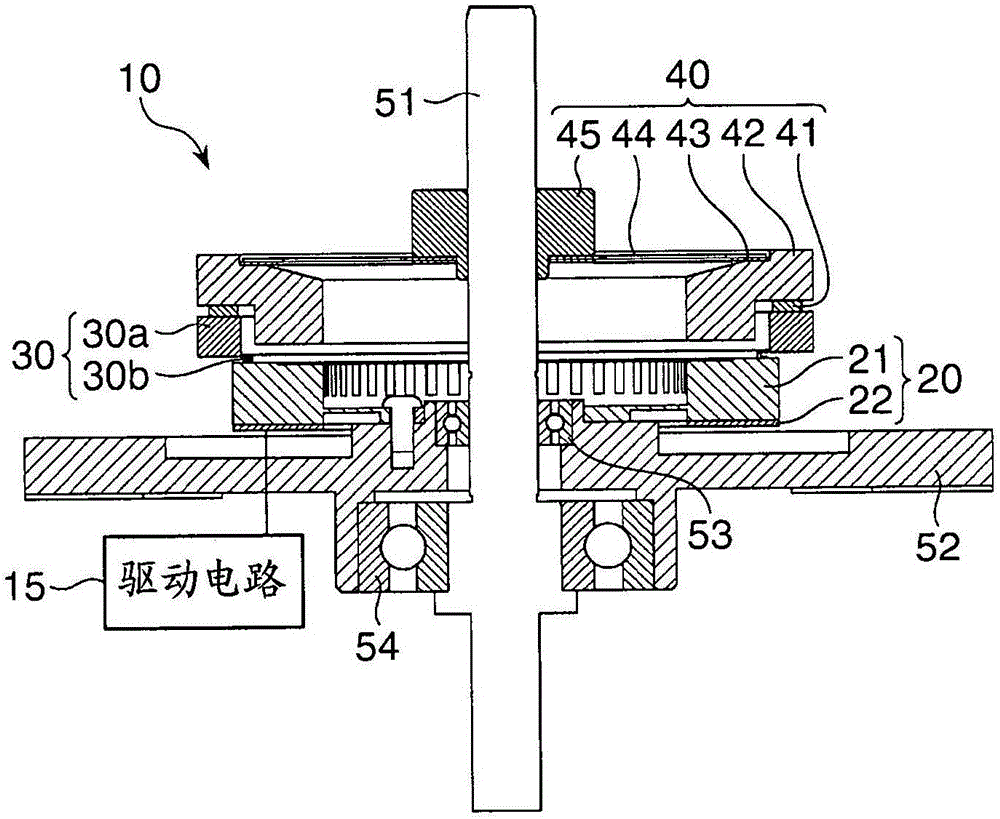

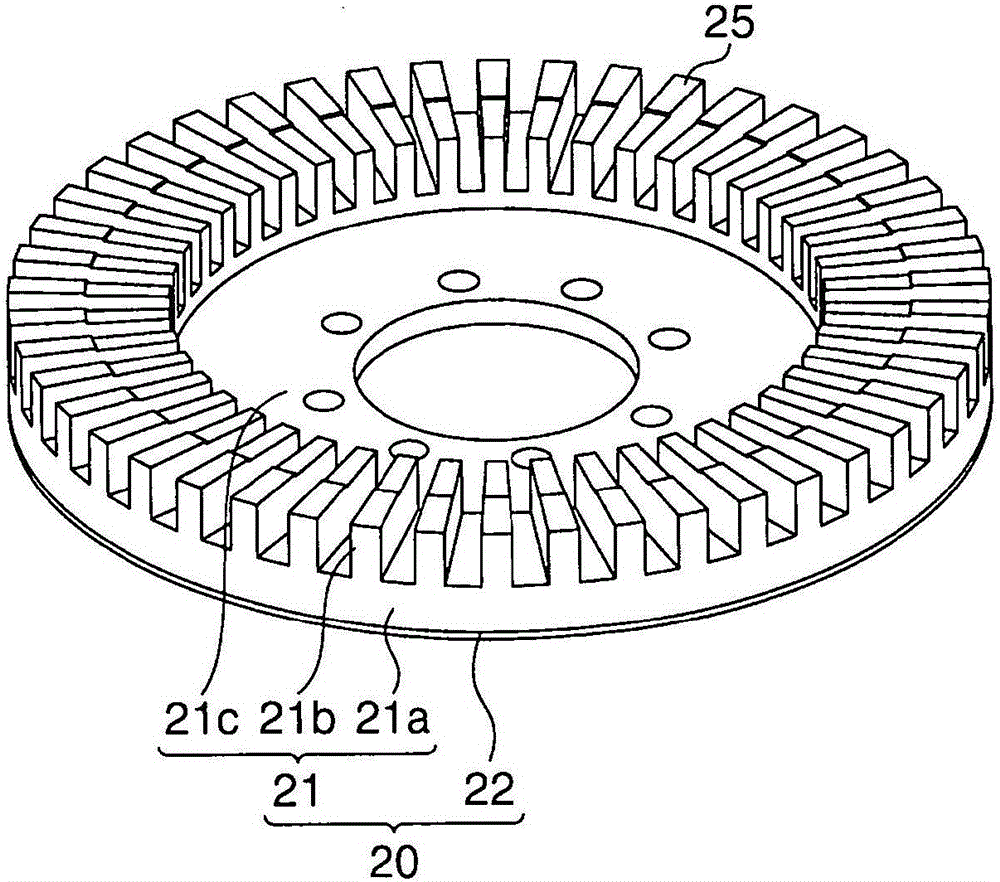

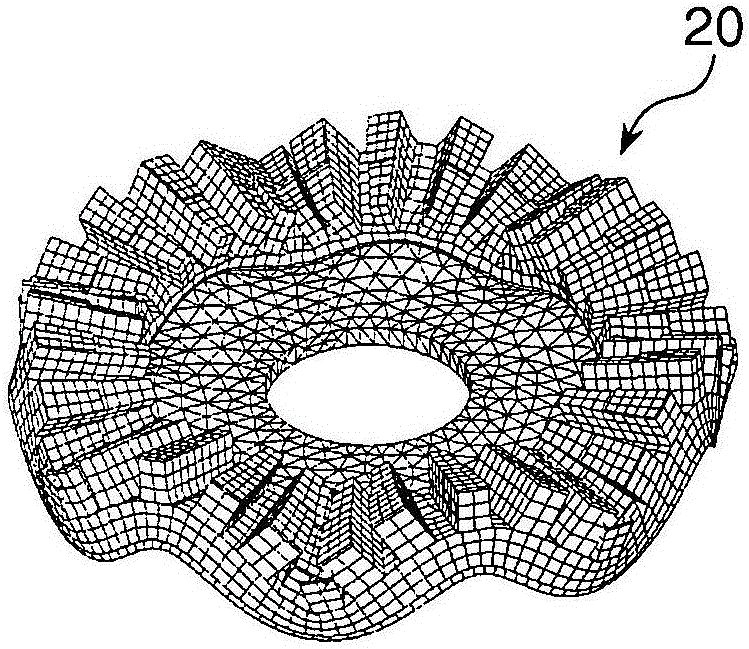

[0039] figure 1is a schematic longitudinal sectional view of the vibration driving device according to the first embodiment of the present invention. The vibration drive device includes a vibration actuator 10 and a drive circuit 15 for driving the vibration actuator 10 . The vibration actuator 10 includes a vibrating element 20, a driven element 30, and a pressing mechanism 40, each of which is formed in a ring shape. In addition, the vibration actuator 10 includes a shaft 51 , a housing 52 , and bearings 53 and 54 .

[0040] The vibration element 20 includes a piezoelectric element 22 which is an electromechanical energy conversion element and an elastic body 21 joined to the elastic body 21 . The pressing mechanism 40 includes a vibration-isolating rubber 41 , a pressure spring receiving part 42 , a pressure spring receiving rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com