DC-DC (Direct Current-Direct Current) switching power supply working method based on FCCM (Forced Continuous Conduction Mode) and control circuit

A technology of switching power supply and control circuit, which is applied in the direction of control/regulation system, electrical components, and adjustment of electrical variables, etc. It can solve problems such as lack of control, large output ripple, and burnout of switch tubes, and achieve good economic and social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

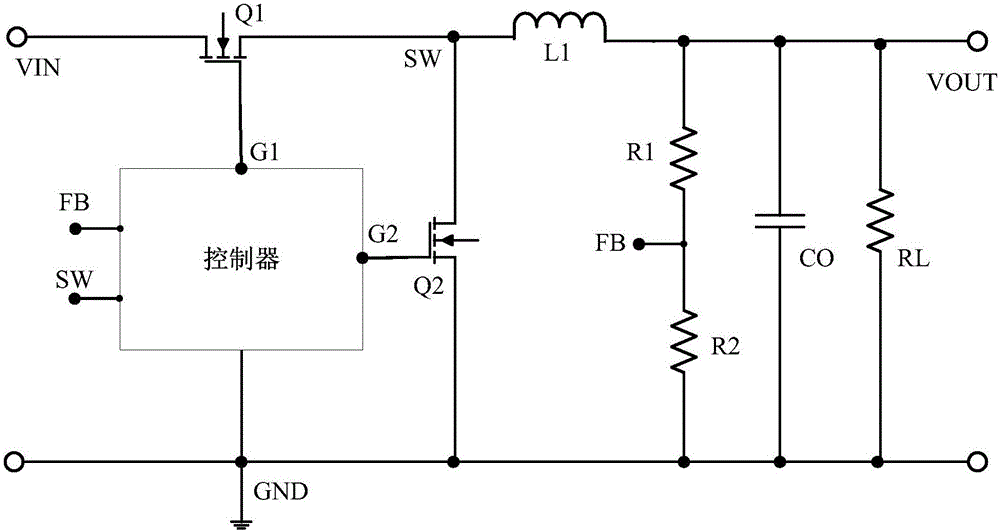

[0021] Such as image 3 As shown, the DC-DC switching power supply control circuit of the present invention includes a voltage input terminal VIN, a voltage output terminal VOUT, an inductor L1, a capacitor CO (capacitance at the output terminal), a load RL, an upper tube Q1, a lower tube Q2 and a controller. DC-DC switching power supply circuit. Among them, the upper tube Q1 and the lower tube Q2 are both MOS tubes, the upper tube Q1 is connected to the input power supply and one end of the inductor, and is a switching tube for controlling the peak current, and the lower tube Q2 is connected to the input ground and one end of the inductor, and is a freewheeling tube.

[0022] Specifically, in the DC-DC switching power supply circuit, the drain of the upper transistor Q1 is connected to the voltage input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com