Preparation method of ternary positive electrode material with low-pH, high-compactness and high cycle performance

A cycle performance, positive electrode material technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of low capacity retention, high price, low compaction, etc., to achieve good cycle stability, high discharge specific capacity, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

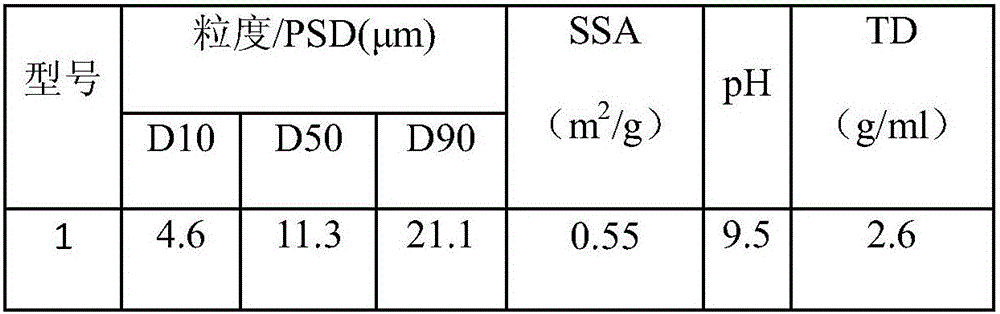

Image

Examples

Embodiment Construction

[0013] Embodiments of the inventive method comprise the following steps:

[0014] Step 1: Perform three-dimensional mechanical mixing of the 523-type ternary precursor with a particle size D50 of 15 μm and battery-grade lithium carbonate at a ratio of Li / M=0.5 for 4 hours, the weight of the mixing ball: material weight=1.5:1, Then sinter in an air-ventilated sintering furnace, the temperature curve is: room temperature → 2h → 600°C → 5h → 940°C → 10h → 940°C, naturally cool with the furnace, and the air flow is 40L / min. Grinding and crushing after cooling to obtain intermediate 1;

[0015] Step 2: Take lithium carbonate of the same weight in step 1 and carry out three-dimensional mechanical mixing with intermediate 1 for 4 hours, and then sinter in an air-ventilated sintering furnace. The temperature curve is: room temperature → 2h → 600°C → 5h → 940°C ℃→10h→940℃, natural cooling with the furnace, the air flow is 40L / min. Grinding and crushing after cooling to obtain interme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com