Flexible display screen substrate and preparation method thereof and preparation method of flexible display screen

A flexible display and substrate technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, instruments, etc., can solve problems that limit the preparation of high-quality flexible displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

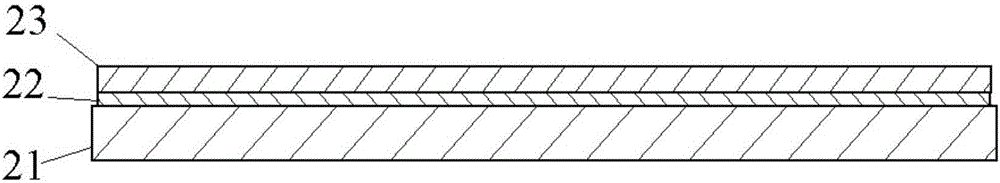

[0030] Such as figure 2 Shown is a schematic structural view of the substrate used to make a flexible display in this embodiment, including a supporting substrate 21 and a flexible substrate 23, and a bonding glue is arranged between the supporting substrate 21 and the flexible substrate 23 Layer 22, the bonding adhesive layer 22 is used to adhere the flexible substrate 23 to the supporting substrate 21, and the adhesive force of the bonding adhesive layer 22 changes with the ambient temperature. The bonding adhesive layer 22 is a temperature-controlling adhesive layer, wherein temperature control means that the adhesive force of the bonding adhesive layer will change when the ambient temperature changes.

[0031] figure 2 The preparation method of the substrate for making a flexible display shown in is as follows: firstly, take glue whose adhesive force changes with the change of ambient temperature; then apply the glue on the supporting substrate 21 to form a bonding glue...

Embodiment 2

[0040] Such as figure 2 Shown is a schematic structural view of the substrate used to make a flexible display in this embodiment, including a supporting substrate 21 and a flexible substrate 23, and a bonding glue is arranged between the supporting substrate 21 and the flexible substrate 23 Layer 22, the bonding adhesive layer 22 is used to adhere the flexible substrate 23 to the supporting substrate 21, and the adhesive force of the bonding adhesive layer 22 changes with the ambient temperature. The bonding adhesive layer 22 is composed of a temperature-controlled adhesive layer, wherein temperature control means that the adhesive force of the bonding adhesive layer will change when the ambient temperature changes.

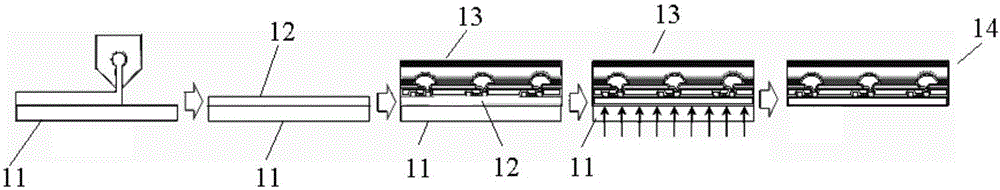

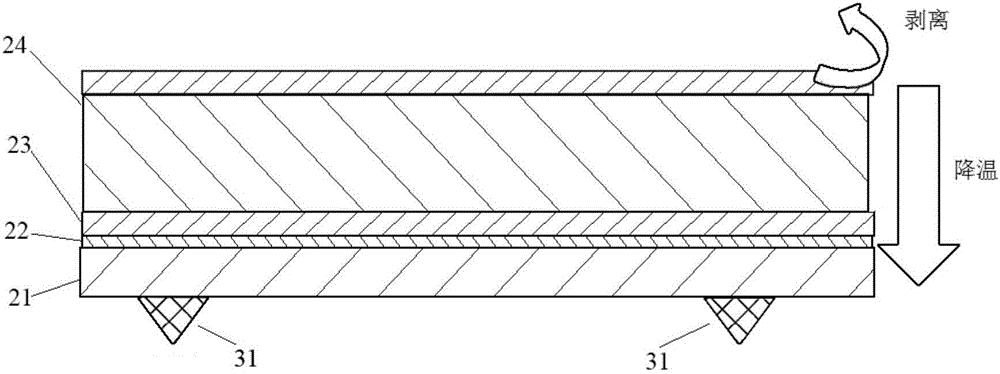

[0041] Similar to Example 1, such as image 3 As shown, it is a schematic diagram of the method for preparing a flexible display in this embodiment, wherein the support substrate fixing device 31 is used to fix the support substrate 21, and then coat a layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com