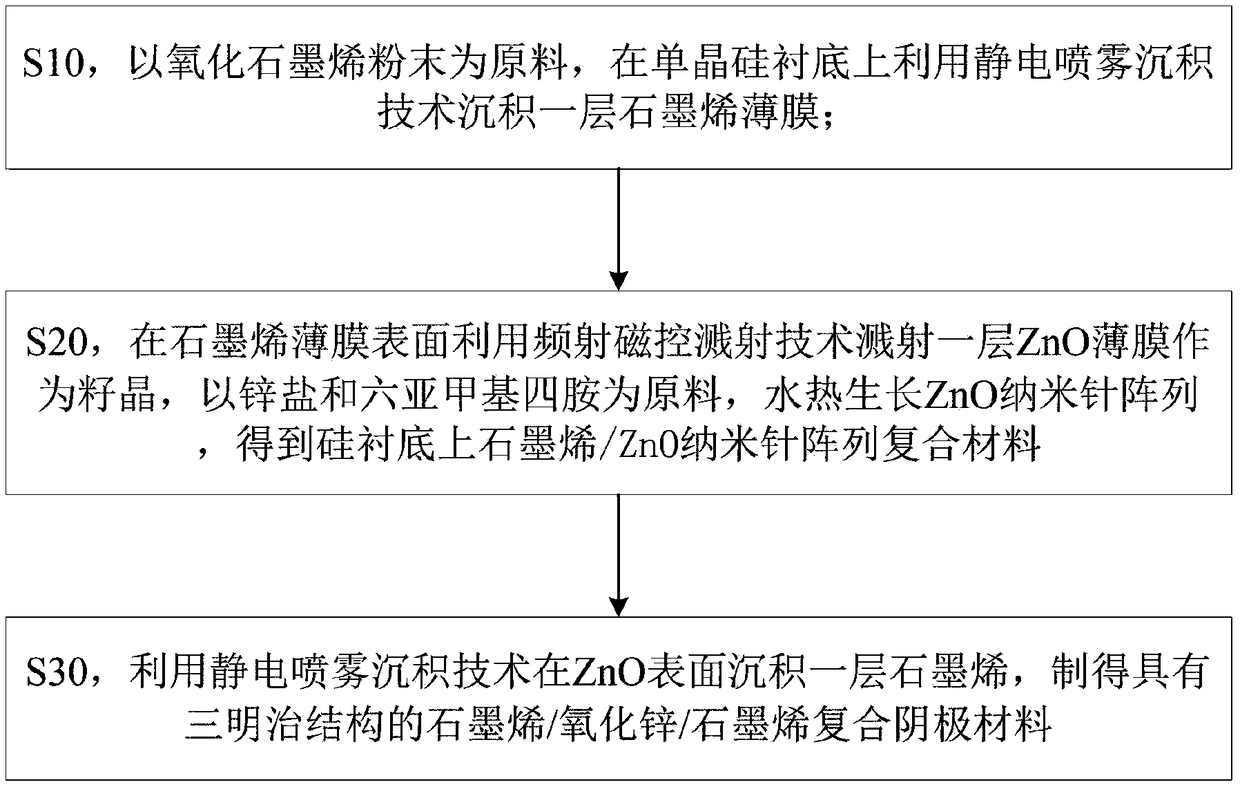

A kind of preparation method of composite cathode material of graphene/zinc oxide/graphene sandwich structure for field emission

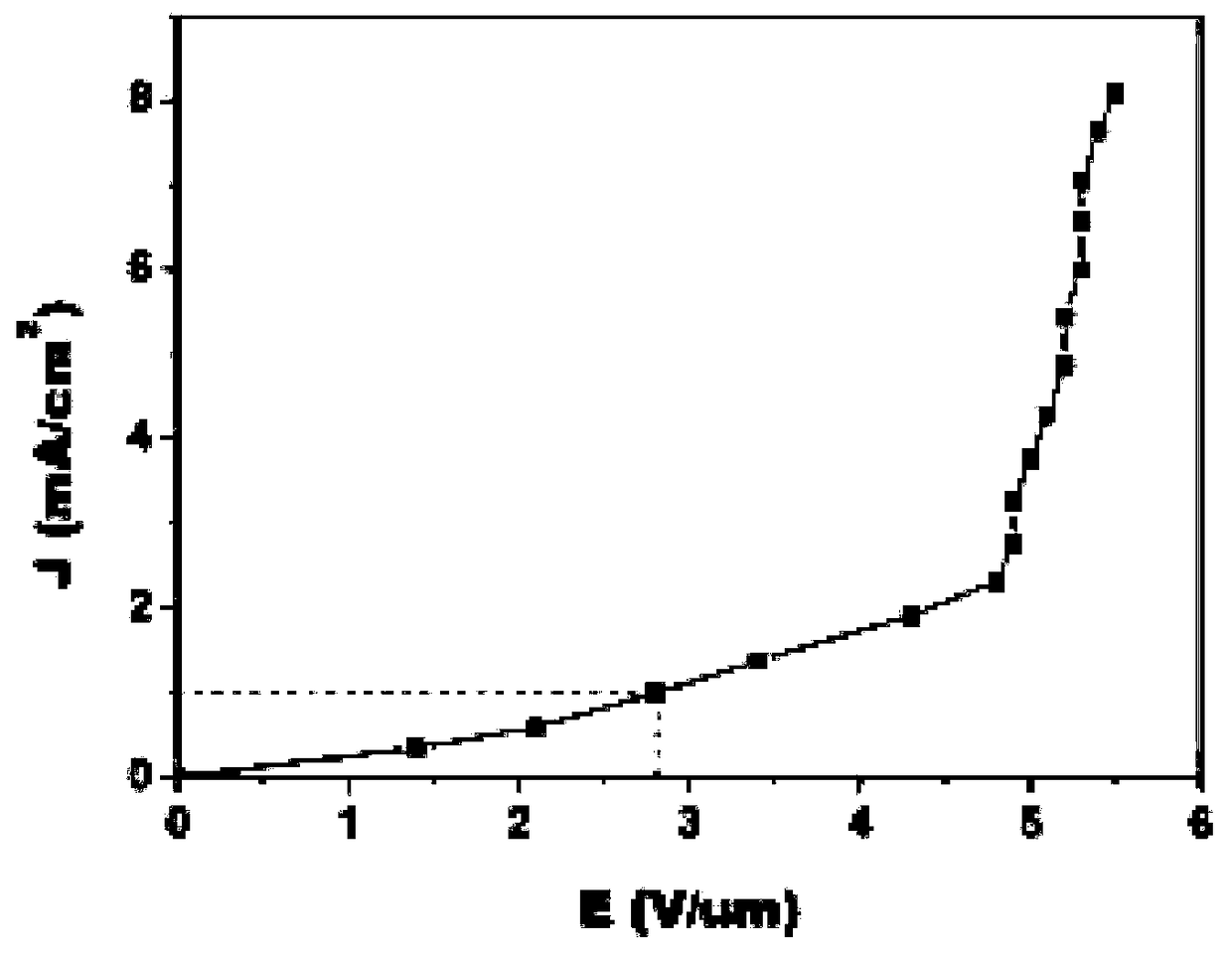

A technology of ene sandwich and composite cathode, which is applied in nanotechnology for materials and surface science, cold cathode manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of stability and controllability of directional ZnO nanoneedle arrays Mature, insufficient understanding of the law of influence, field enhancement factor reduction, etc., to achieve the effect of low launch field strength, low cost, and low launch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

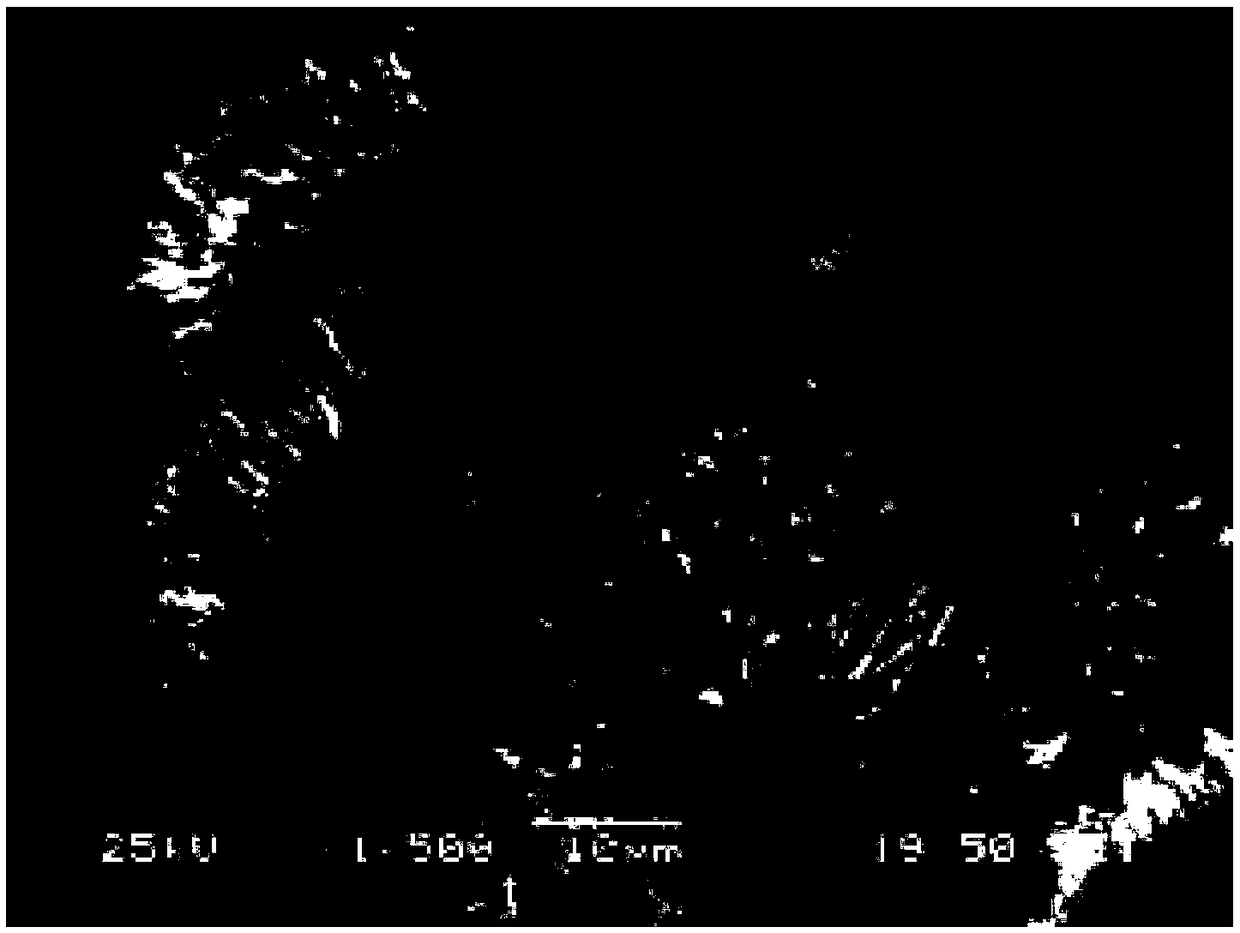

[0038] like figure 1As shown, measure 33.33ml of analytically pure 1,2-propanediol with a mass percentage of 99.5% and 66.67ml of analytically pure ethanol with a mass percentage of 99.8%, and mix the two fully to obtain 1,2-propanediol and 100ml of a mixed solution with an absolute ethanol volume ratio of 1:2, 0.05mmol mass percentage of 99% analytically pure graphene oxide powder was dissolved in the mixed solution, and after ultrasonic stirring for 1h, an electrostatic spray deposition (ESD) was obtained. Suspend the precursor solution; then fix the N-type monocrystalline silicon polished wafer (resistivity 3) on the substrate splint, heat the substrate temperature to 100°C, and adjust the capillary nozzle of the electrostatic spray deposition device and the substrate The distance between them is 5cm, and the DC voltage is 12kV. Add the prepared electrostatic spray deposition precursor solution to the electrostatic spray deposition device, set the liquid flow rate of the e...

Embodiment 2

[0041] like figure 1 As shown, measure 50ml of analytically pure 1,2-propanediol with a mass percentage of 99.5% and 50ml of analytically pure absolute ethanol with a mass percentage of 99.8%, and mix the two thoroughly to obtain 1,2-propanediol and anhydrous The volume ratio of ethanol is 100ml of mixed solution of 1:1, and 0.03mmol mass percent of 99% analytically pure graphene oxide powder is dissolved in the mixed solution, and after ultrasonic stirring for 1.5h, an electrostatic spray deposition (electrostatic spray deposition) is obtained. Then fix the N-type monocrystalline silicon polished wafer (resistivity 8.1) on the substrate splint, heat the substrate temperature to 150°C, adjust the capillary nozzle and lining of the electrostatic spray deposition device The distance between the bottoms is 6cm, and the DC voltage is 11kV. Add the prepared electrostatic spray deposition precursor solution to the electrostatic spray deposition device, set the spray speed of the el...

Embodiment 3

[0044] like figure 1 As shown, measure 33.33ml of analytically pure 1,2-propanediol with a mass percentage of 99.5% and 66.67ml of analytically pure ethanol with a mass percentage of 99.8%, and mix the two fully to obtain 1,2-propanediol and 100ml of a mixed solution with a volume ratio of absolute ethanol of 1:2, 0.02 mmol of analytically pure graphene oxide powder with a mass percentage of 99% was dissolved in the mixed solution, and after ultrasonic stirring for 1 hour, electrostatic spray deposition (electrostatic spray deposition) was obtained. The suspension precursor solution used; then fix the N-type monocrystalline silicon polished wafer (resistivity 5.8) on the substrate splint, heat the substrate temperature to 200 ° C, adjust the capillary nozzle and the electrostatic spray deposition device The distance between the substrates is 6cm, and the DC voltage is 10kV. Add the prepared electrostatic spray deposition precursor solution to the electrostatic spray depositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com