Fire ion detector

An ion detector and detector technology, which is used in the production of important core components in the instrument industry and in the field of chromatography, can solve the problems of easy formation of water droplets, natural and man-made disasters, and the inability to achieve as low as 0.1ppbv/v, so as to avoid potential safety hazards and solve problems. Monitoring is difficult and the effect of saving continuous economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

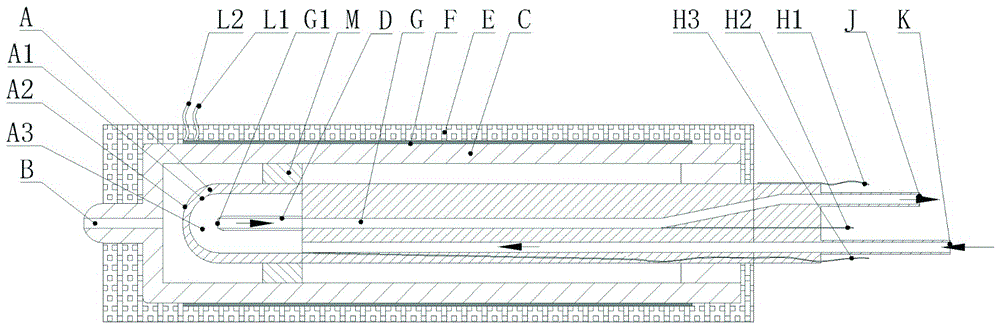

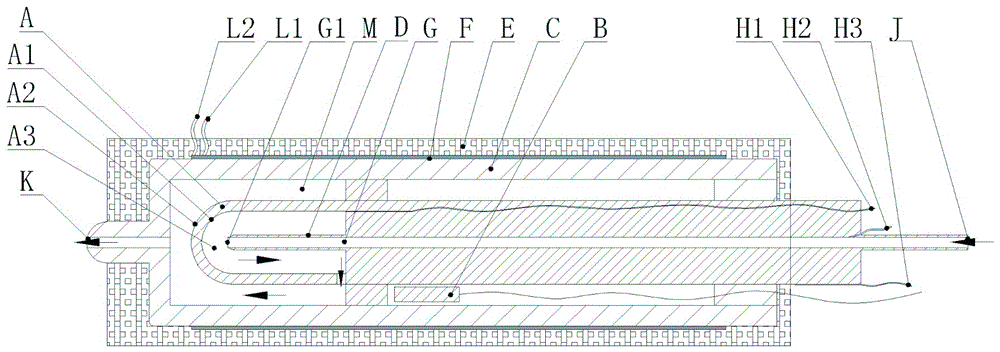

[0008] First, high-purity rare earth, yttrium, iridium, ruthenium, calcium, zirconium, iridium, titanium, nickel, palladium, platinum, manganese, and other elemental minerals or oxide powders are synthesized in proportion to produce different specifications and appropriate crystals that are detectors The main body and the airway, see tubes A and D in the drawing. The inner and outer surfaces of tube A and the inner wall of tube D are coated with synthetic platinum slurry of special platinum and various metals, after drying, impurity removal and calibration. Finally, use appropriate temperature, step temperature from 40°C to 1200°C, and determine the best quality of constant temperature firing at each stage by the length of time. In this way, the core components we need are produced.

[0009] Secondly, make appropriate quartz tubes and constant temperature modules, as shown in C and M in the drawing, and make a high-temperature heating resistance layer or heating high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com