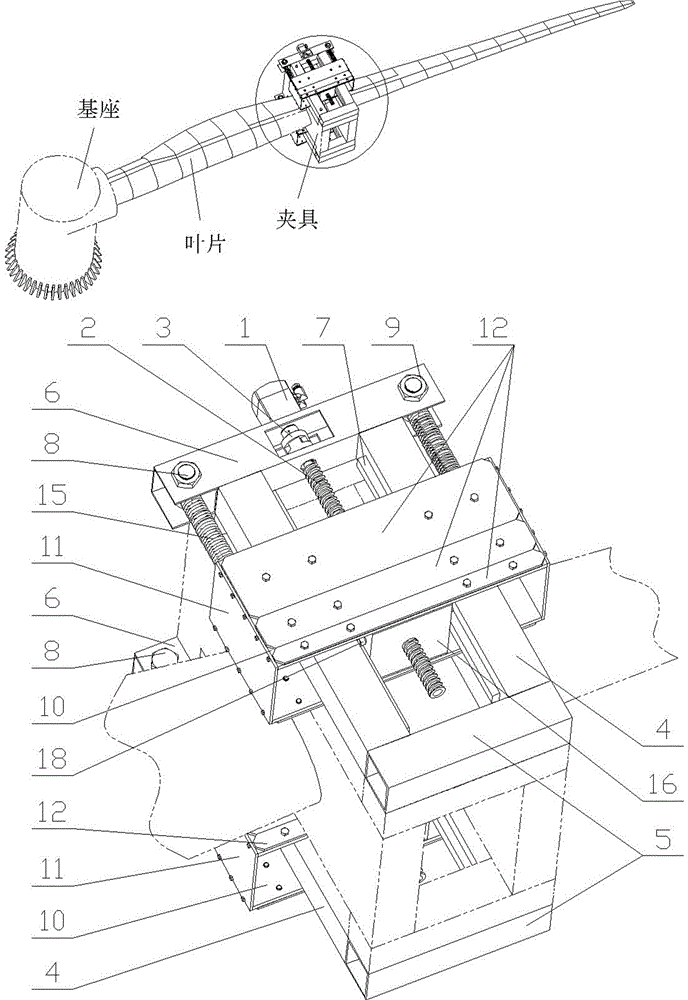

Wind power blade fatigue loading test device

A technology of fatigue loading and testing equipment, which is applied in the direction of measuring equipment, testing material strength by applying repetitive force/pulsation force, testing mechanical parts, etc., and can solve problems such as poor assembly process, low efficiency, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

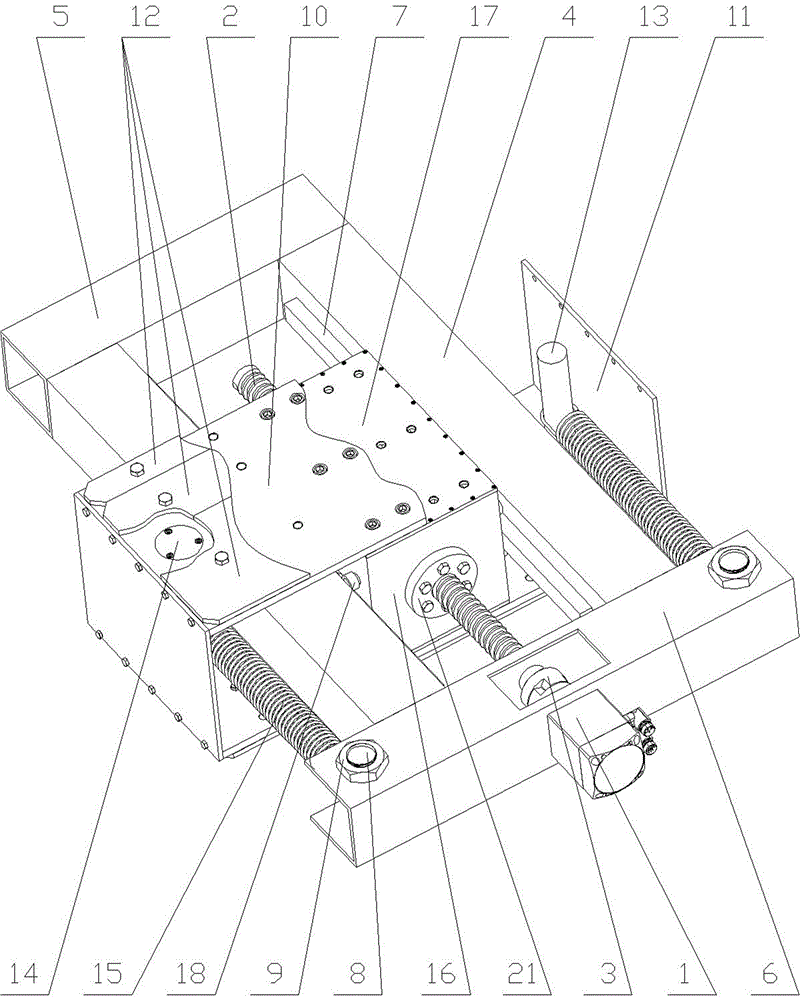

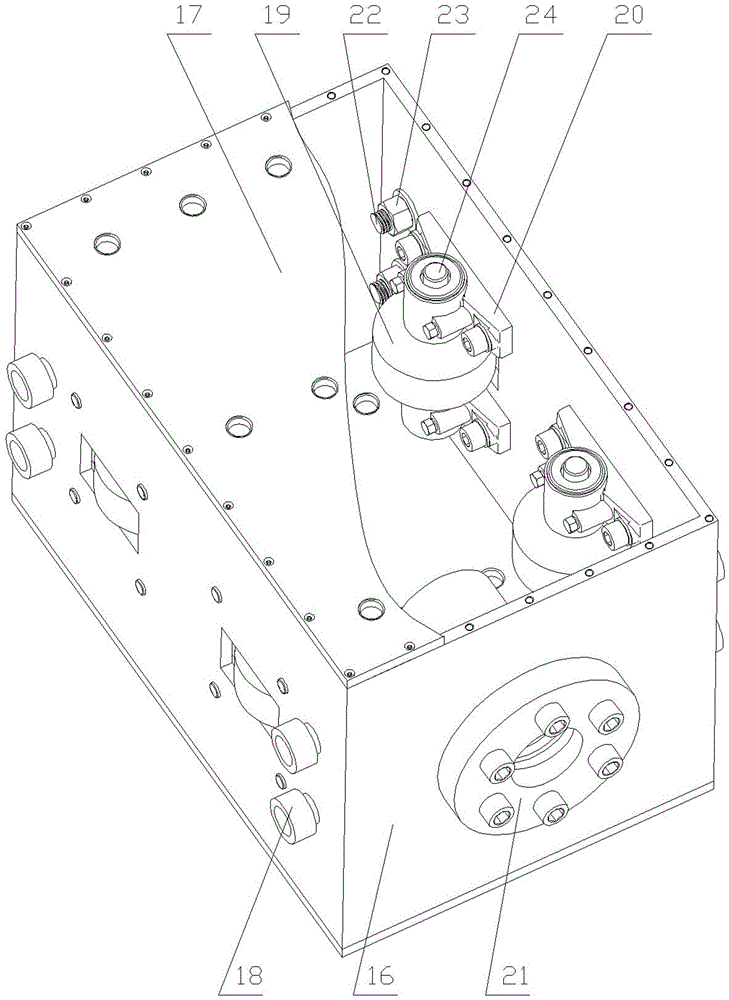

[0024] 1. Servo motor 2, lead screw 3, coupling 4, pillar 5, beam I 6, beam II 7, guide rail 8, pin shaft I 9, nut I 10, mounting plate 11, side plate 12, counterweight 13, Pin shaft II 14, baffle plate 15, spring 16, box body 17, cover plate 18, guide wheel I 19, guide wheel II 20, support 21, screw nut 22, pin shaft III 23, nut II 24, pin shaft IV.

[0025] exist Figure 1-Figure 3 In the shown embodiment: on the basis of the prior art, the present invention has equal lengths and two pillars 4 made of square tubes are located in the same plane, and one end is fixedly connected by a beam I5 made of a square tube, and the length of the beam I5 is equal to After the connection, the distance between the outer sides of the two pillars 4, and the other end is fixedly connected by a beam II6 made of a square tube. The two ends of the beam II6 protruding from the outer sides of the two pillars 4 are provided with axes perpendicular to where the two pillars 4 are located. In the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com