High-temperature cylindrical compression member test spray cooling system

A pressure component, water spray cooling technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of splashing, water jetting away, etc., and achieve the effect of flexible installation and disassembly, uniform water flow, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

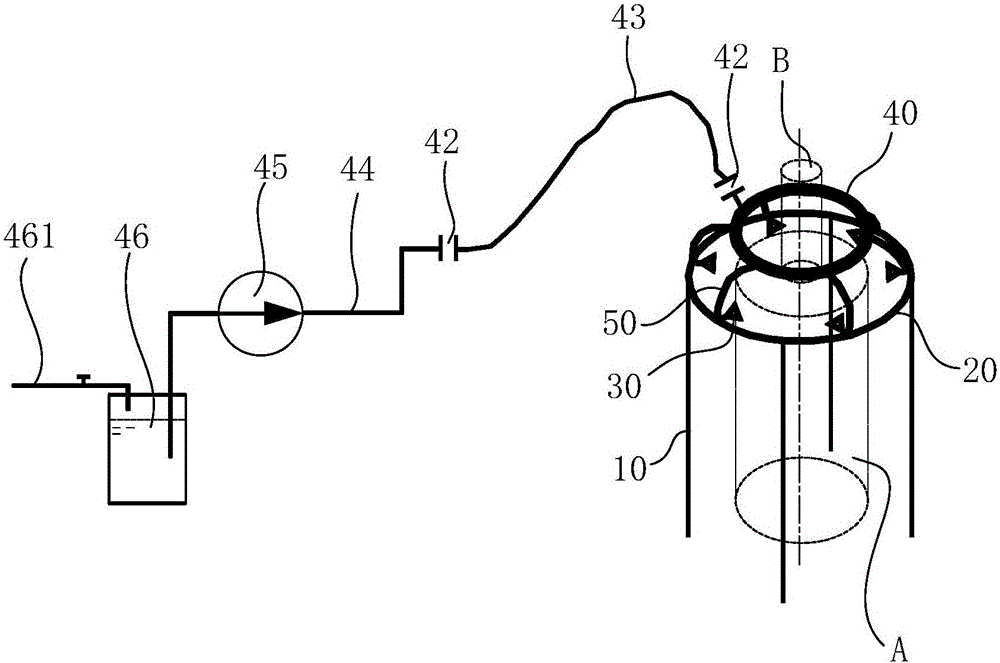

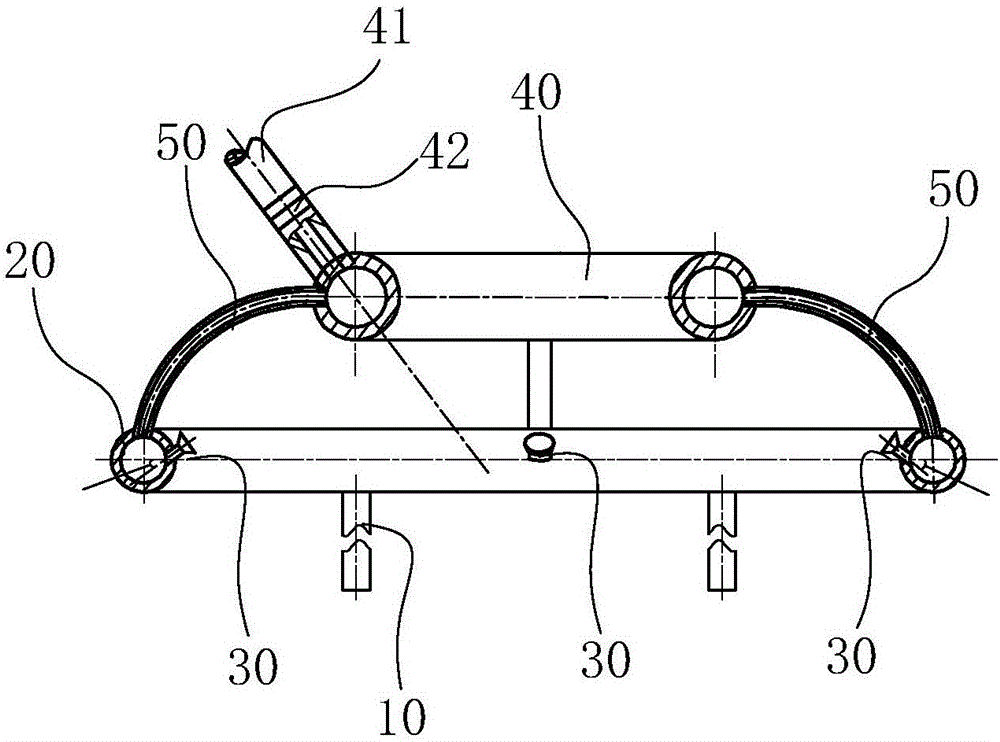

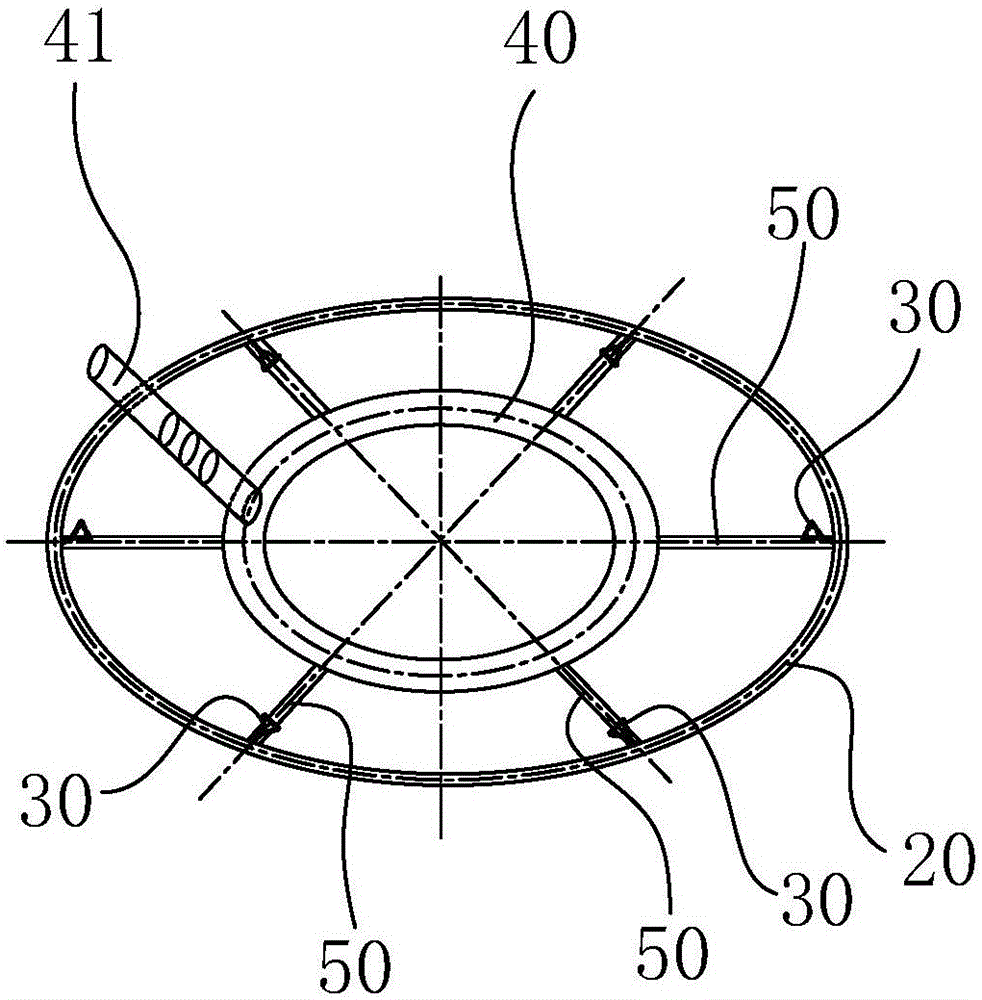

[0023] combine Figure 1 to Figure 3 , the present invention is further described:

[0024] High-temperature cylindrical pressure member test water spray cooling system, including a metal support 10 around the cylindrical pressure member A, the metal support 10 is provided with a secondary water distribution ring pipe 20, and the secondary water distribution ring pipe 20 as a whole It is a ring-shaped structure matching the contour of the cylindrical pressure member A, the ring surface of the secondary water distribution ring pipe 20 is horizontal and coaxially arranged with the cylindrical pressure member A, along the circumference of the secondary water distribution ring pipe 20 A plurality of cooling water nozzles 30 are distributed at intervals, and the water spraying direction of the cooling water nozzles 30 points to the center of the ring surface of the secondary water distribution ring pipe 20 and is obliquely upward.

[0025] combine figure 1 As shown, the load appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com