Measuring device and method for optical element damage threshold under vacuum environment

A technology of optical components and damage threshold, which is applied in the direction of testing optical performance, etc., can solve the problems of optical component measurement reliability reduction, no spot quality monitoring, spot area difference, etc., to achieve accurate measurement, high accuracy, and strong functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

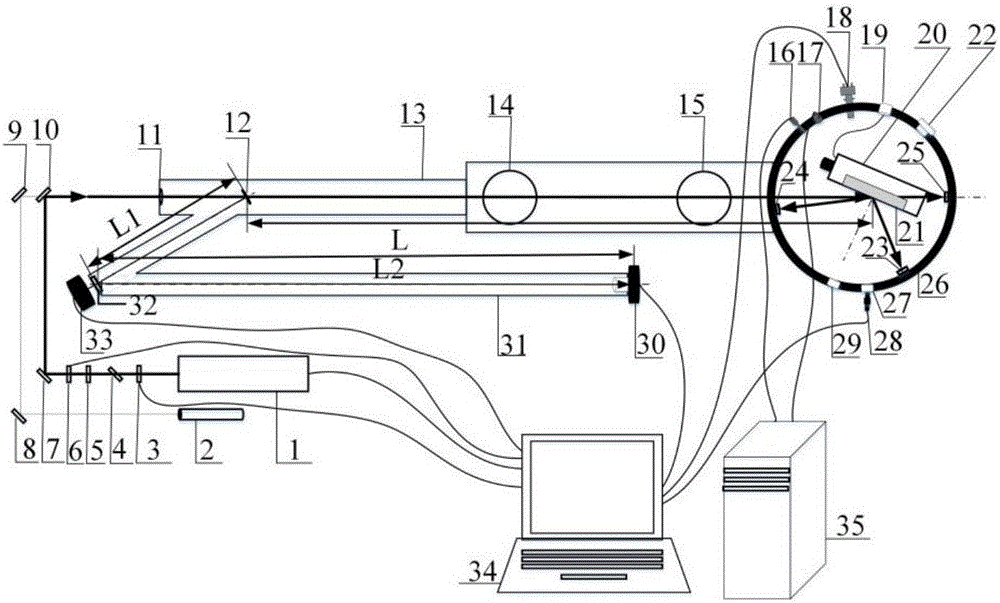

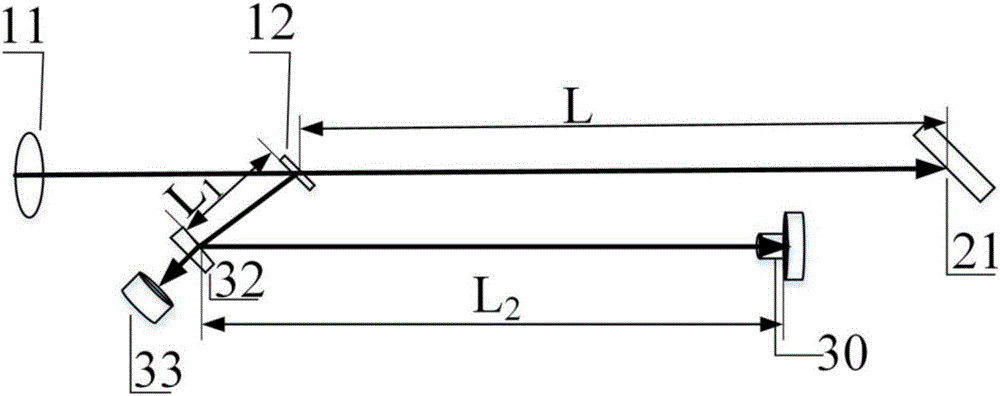

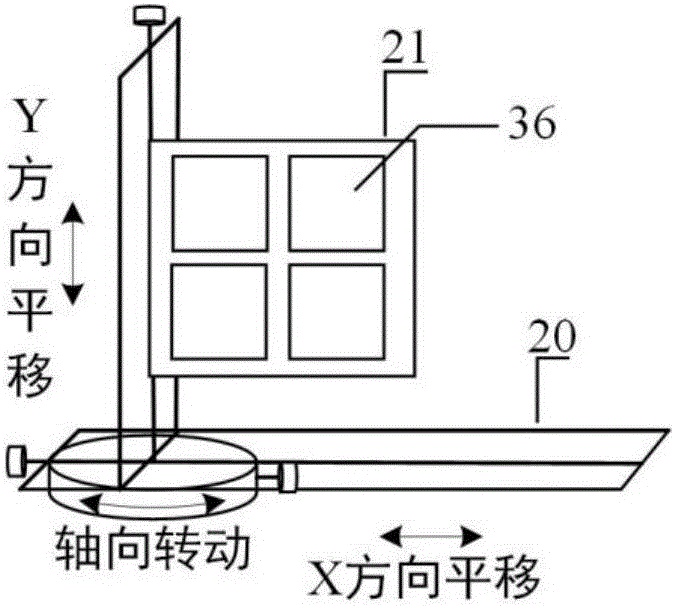

[0040] Example: see figure 1 , figure 2 and image 3 , figure 1 It is a schematic diagram of the laser damage threshold measurement device in vacuum environment of the present invention. In the figure, 1 is the measurement laser, 2 is the He-Ne laser, 3 is the 1 / 2 wave plate, 4 is the polarizer, 5 is the 1 / 2 wave plate, 6 is the electronic shutter, 7 and 10 are the measuring beam mirrors, 8 and 9 are He-Ne optical reflectors, 11 is a focusing lens, 12 is a beam splitter, 13 is a main beam transmission pipe for measurement, 14 is a molecular pump interface, 15 is an ion pump interface, 16 is a low vacuum gauge, and 17 is a high vacuum gauge , 18 is the residual gas analyzer, 19 is the three-dimensional mobile platform control cable interface, 20 is the three-dimensional mobile platform, 21 is the sample fixture to be tested, 22 is the spare interface, 23, 24 and 25 are energy absorbing materials, 26 is the measurement room Cavity, 27 is a monitoring window, 28 is a CCD sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com