High-precision inclinometer calibration method

A calibration method and technology of inclinometers, applied to instruments, measuring devices, etc., can solve the problems of large influence, large calibration errors, and poor measurement synchronization, and achieve the effect of good measurement synchronization and small calibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

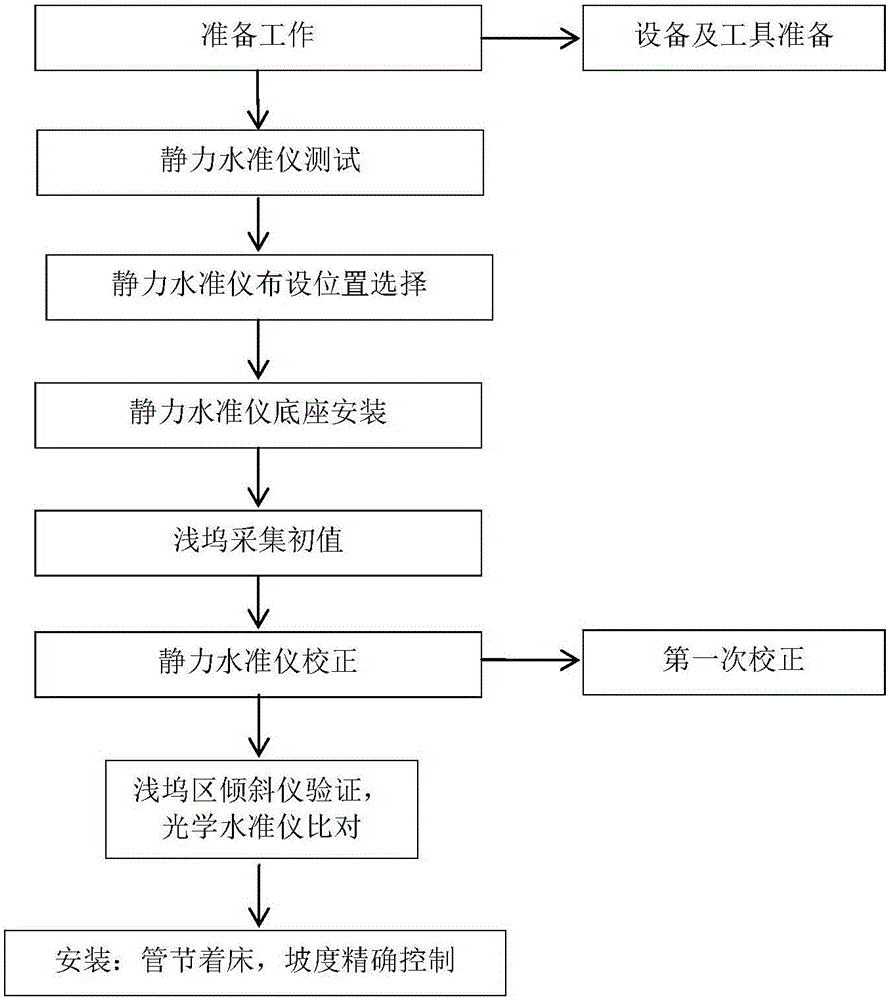

[0030] Such as figure 1 , a high-precision inclinometer calibration method, comprising steps:

[0031] A. Initial value of shallow dock collection:

[0032] In this embodiment, before the initial value is collected, preparatory work needs to be carried out, specifically equipment and tools are prepared. On the basis of relatively stable land, data output and stability testing of the static level are carried out (i.e. figure 1 "Static level test" in the "Static level test"), and at the same time select the layout position of the static level;

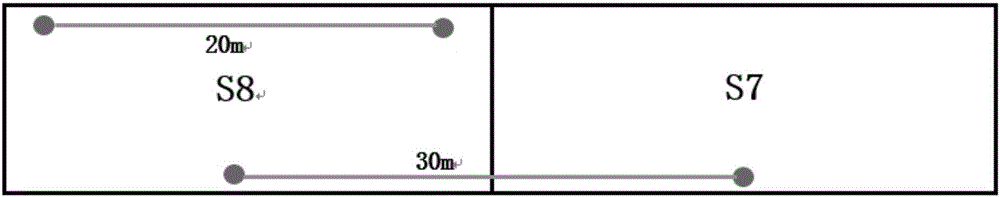

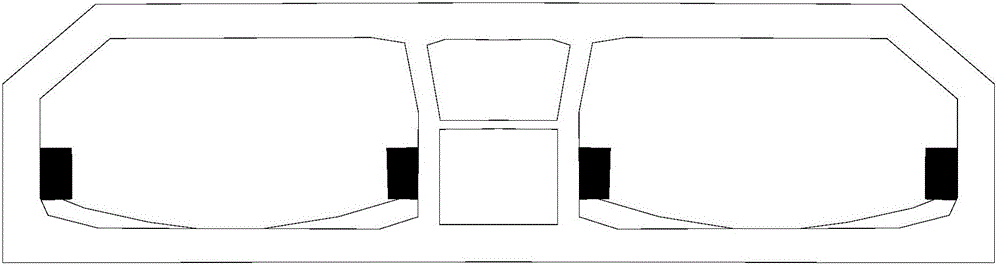

[0033] The pipe joint to be installed of the immersed pipe enters the shallow dock area, and a number of static levels and the first inclinometer are installed in the pipe joint to be installed (when the static level is installed, it is installed on the side wall and the middle of the roadway of the pipe joint. On the fixed base on the ground of the pipe gallery, that is figure 1 "Installation of the static level base", when the stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com