Multi-purpose height ruler

A technology of height gauge and auxiliary gauge, applied in the direction of using mechanical devices, mechanical thickness measurement, mechanical depth measurement, etc., can solve the problems of large investment, limited measurement range and location, and interference of human factors in measurement operations, saving procurement funds, The effect of improving machining efficiency and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

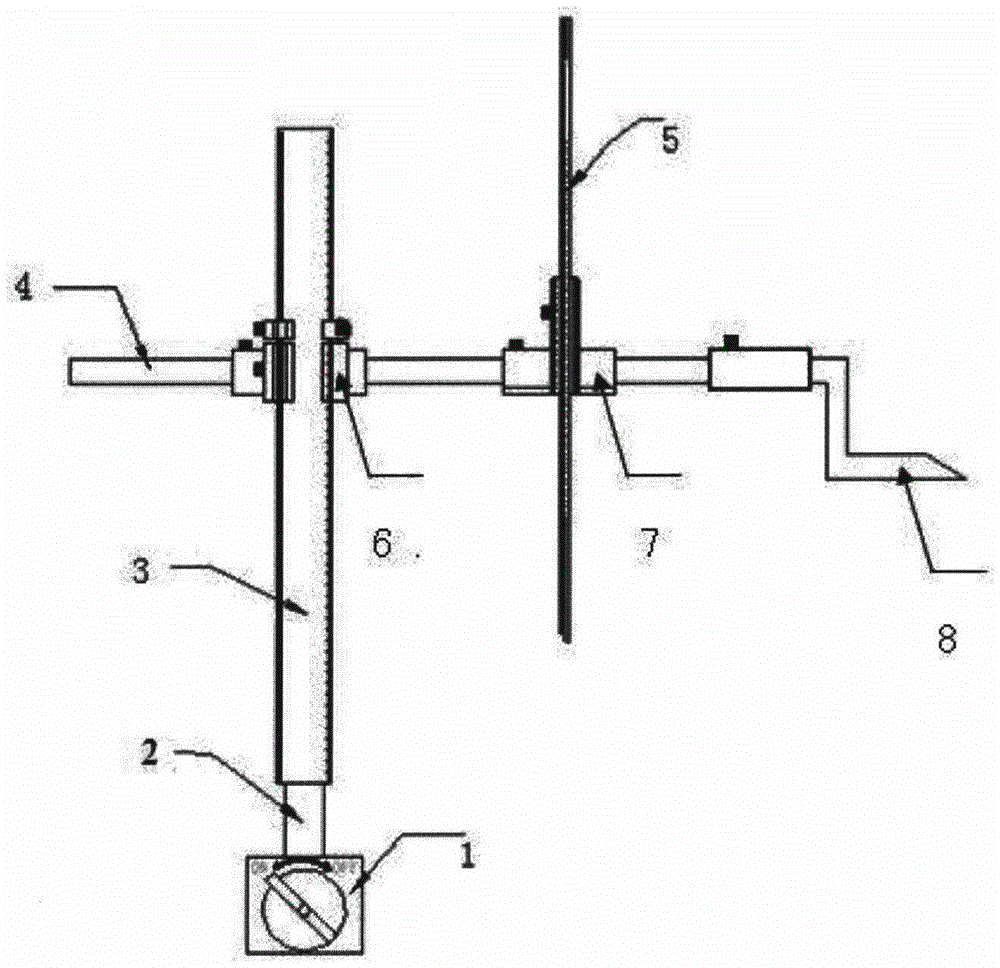

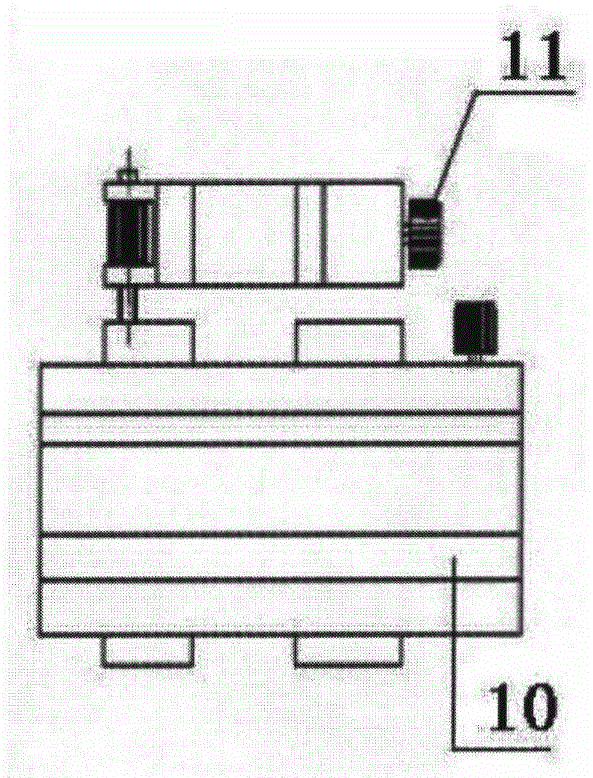

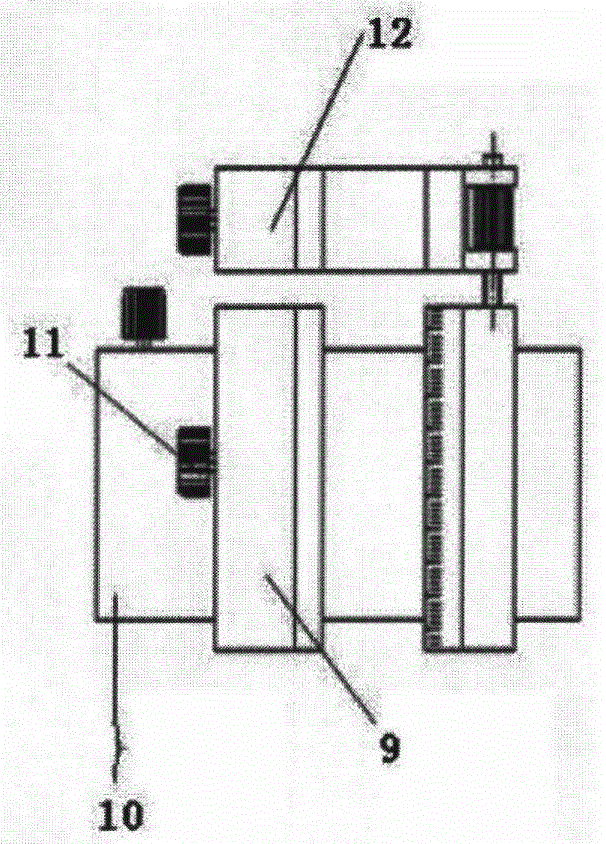

[0013] Such as figure 1 , 2 , 3, and 4, the present invention mainly includes a magnetic base 1, a rotating shaft 2, a main ruler 3, a horizontal auxiliary ruler 4, a vertical auxiliary ruler 5, a ruler frame 6, a ruler frame 7, and measuring claws 8; the rotating shaft 2 passes through a roller bearing Connected to the magnetic base 1, the rotating shaft 2 can rotate; one end of the main ruler 3 is connected to the rotating shaft 2 through an interference fit, and is firmly connected as one. The main ruler 3 can be connected to the rotating shaft 2 with the bearing in the magnetic base 1 as the center line 360 The horizontal sub-ruler 4 is vertically connected to the main ruler 3 through the ruler frame 6. The front side of the ruler frame 6 is provided with a vertical guide rail 9, and the back is provided with a horizontal guide rail 10. The ruler frame 6 is equipped with fastening screws 11. 9 is equipped with a fine-tuning guide rail 12, and the horizontal auxiliary rule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com