Spiral condensing tube-based liquid cooling device

A serpentine condensing tube and liquid cooling technology, applied to fixed tubular conduit components, heat exchange equipment, heat exchanger types, etc., can solve the problems of slow condensation rate, low efficiency, and low efficiency of the condenser, and achieve Improve condensation efficiency, uniform temperature distribution, and speed up condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

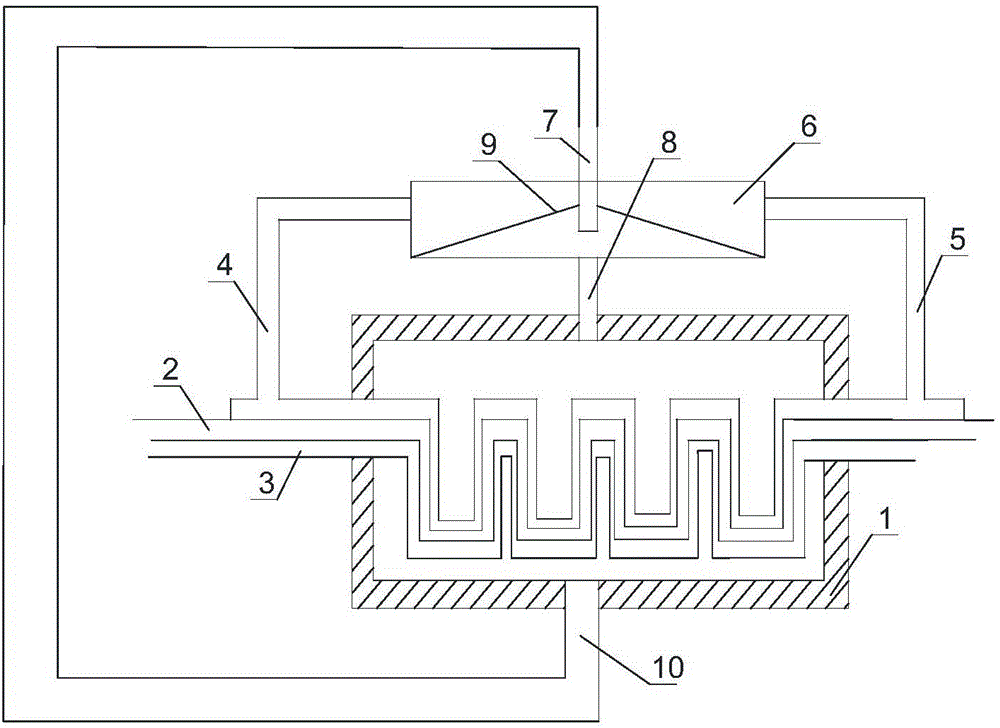

[0022] Such as figure 1 As shown, the liquid cooling device based on the serpentine condenser tube of the present invention includes a condenser 1, a serpentine liquid inlet pipe 2 is installed inside the condenser 1, and a cold air pipe 3 is sleeved on the outside of the serpentine liquid inlet pipe 2 One end of the cold air pipe 3 is connected with an air intake pipe 4, and the air intake pipe 4 is located at one side of the condenser 1, and the other end of the cold air pipe 3 is connected with an air outlet pipe 5 opposite to the air inlet pipe 4, and the air outlet pipe 5 is connected with the air inlet pipe. 4 communicates with an ice chamber 6, the ice chamber 6 is located above the condenser 1, the water inlet pipe 7 is connected above the ice chamber 6, and the water outlet pipe 8 is connected below the ice chamber 6, and the water outlet pipe 8 is connected to the inside of the condenser 1. The cold air pipe 3 inside the condenser 1 is a serpentine pipe that matches ...

Embodiment 2

[0025] Based on Example 1, a partition 9 is installed inside the ice chamber 6, ice cubes are housed in the sealed cavity between the partition 9 and the bottom of the ice chamber, and the water outlet end of the water inlet pipe 7 is located between the partition 9 and the bottom of the ice chamber. In the sealed chamber between them, the air outlet pipe 5 and the air inlet pipe 4 are both in communication with the cavity above the partition 9 .

[0026] The partition divides the ice room into two chambers to facilitate the flow of cold air. After the water inlet pipe is passed into the ice room, the water content in the ice room will increase. If the cold air passes through the ice water, the water content in the cold air will increase. Slow down the flow rate of the cold air. The temperature of the ice water is the combination of tap water and ice. Therefore, the temperature of the ice water in the confinement room will be slightly higher than the temperature of the air-cond...

Embodiment 3

[0028] Based on the above embodiment, a drain pipe 10 is communicated below the condenser 1 , and the lower end of the drain pipe 10 communicates with the water inlet pipe 7 . A temperature sensor is installed inside the condenser 1, and electric valves are installed in the drain pipe 10 and the water inlet pipe 7, and the temperature sensor is connected with the electric valves of the drain pipe 10 and the water inlet pipe 7.

[0029] The drain pipe is used to replace the condensed water in the condenser. The temperature of the condensed water will rise after a period of time. It is necessary to discharge part of the condensed water in the condenser in time and then put fresh ice water into the condenser to keep the condensation inside the condenser. The water is at a lower temperature. The temperature sensor is used to monitor the temperature of the condenser. Once the temperature of the condensed water in the condenser is higher than the preset value, the electric valves in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com