Magnetic force flexible pivot

A flexible pivot and magnetic force technology, applied in the field of flexible pivot design, can solve problems such as fatigue and plastic deformation of mechanical spring leaf connection support, and achieve the effect of simple structure, ensuring concentricity, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

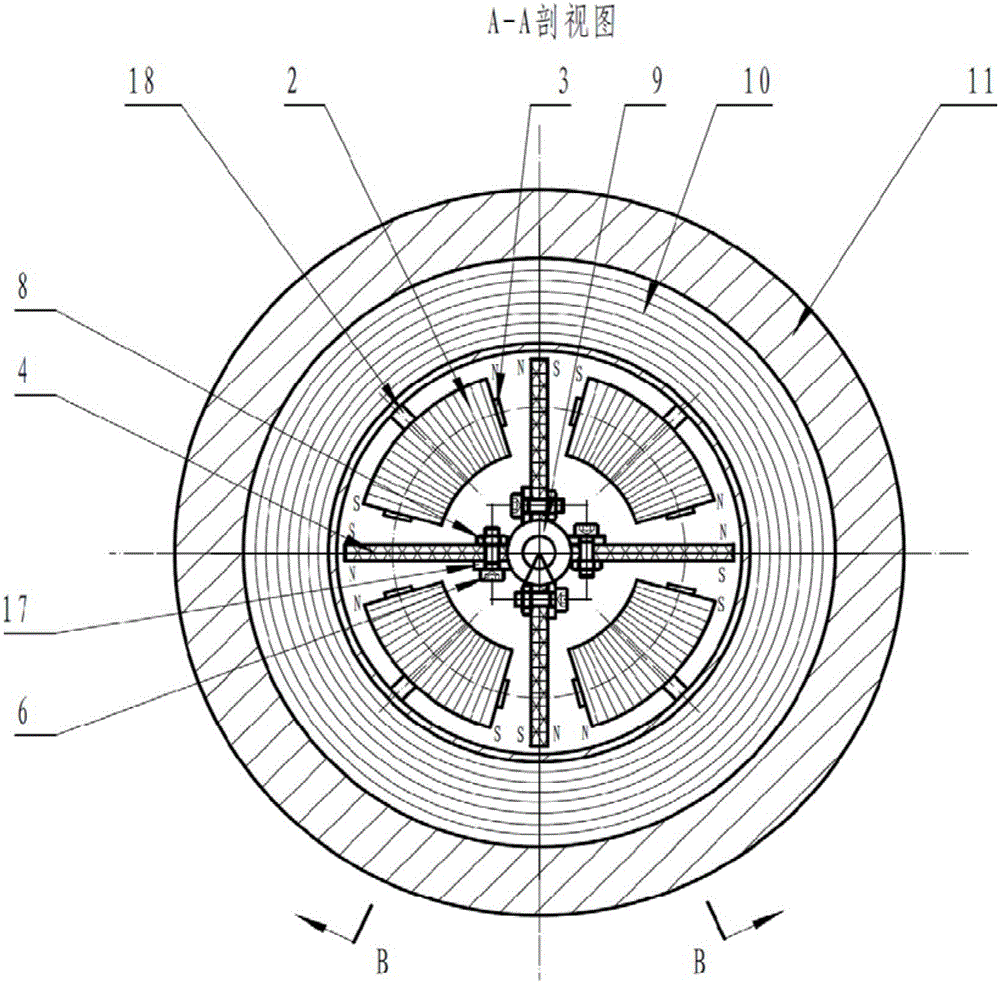

[0029] Embodiment 1: Electromagnetic Magnetic Flexible Pivot

[0030] as attached figure 1 , attached figure 2 As shown, Embodiment 1 of the present invention provides an electromagnetic flexible magnetic pivot, including two parts: a rotor and a stator;

[0031] Further, the rotor includes an upper cover, a lower cover and a permanent magnet shaft, and the connection relationship is as follows: the upper cover and the lower cover are kept parallel and concentric with the permanent magnet shaft, and the upper cover, the lower cover and the permanent magnet shaft are fixed by rotor fixing screws 7 is fixed with the rotor nut 16, and the gasket 15 with anti-loosening ability is used for anti-loosening;

[0032] Further, the upper cover includes the rotor upper cover 5 and the upper cover thrust permanent magnet 1, and its connection relationship is: the upper cover thrust permanent magnet 1 is bonded and fixed in the groove of the rotor upper cover 5, and the upper cover thru...

Embodiment 2

[0041] Embodiment 2: Permanent Magnetic Flexible Pivot

[0042] as attached image 3 , attached Figure 4 As shown, Embodiment 2 of the present invention provides a permanent magnetic flexible pivot. The difference from Embodiment 1 is that the stator thrust magnet and the stator anti-rotation magnet of the permanent magnet magnetic flexible pivot are permanent Magnet form, as follows:

[0043] The stator of the permanent magnetic flexible pivot includes a stator housing 11, an upper thrust permanent magnet 20, a lower thrust permanent magnet 21, and an anti-rotation permanent magnet 19; the connection relationship is: the upper thrust permanent magnet 20 is bonded fixed in the upper groove of the stator housing 11, and installed in parallel with the upper cover thrust permanent magnet 1, coaxial and magnetically mutually exclusive; the lower thrust permanent magnet 21 is bonded and fixed in the lower groove of the stator housing 11, Parallel and coaxial with the thrust per...

Embodiment 3

[0046] Example 3: Composite Magnetic Flexible Pivot

[0047] Embodiment 3 of the present invention provides a composite magnetic flexible pivot. The difference from Embodiment 1 and Embodiment 2 is that the stator thrust magnet and stator anti-rotation magnet of the magnetic flexible pivot are permanent magnets and electromagnetic coils. Mixed use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com