An air compressor energy efficiency online detection and evaluation system and method

An air compressor and evaluation system technology, applied in pump testing, measuring devices, mechanical equipment, etc., can solve the problems of narrow data collection range, compressor energy efficiency detection, and no energy saving effect, and achieves convenient on-site deployment and increased reliability. performance, saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

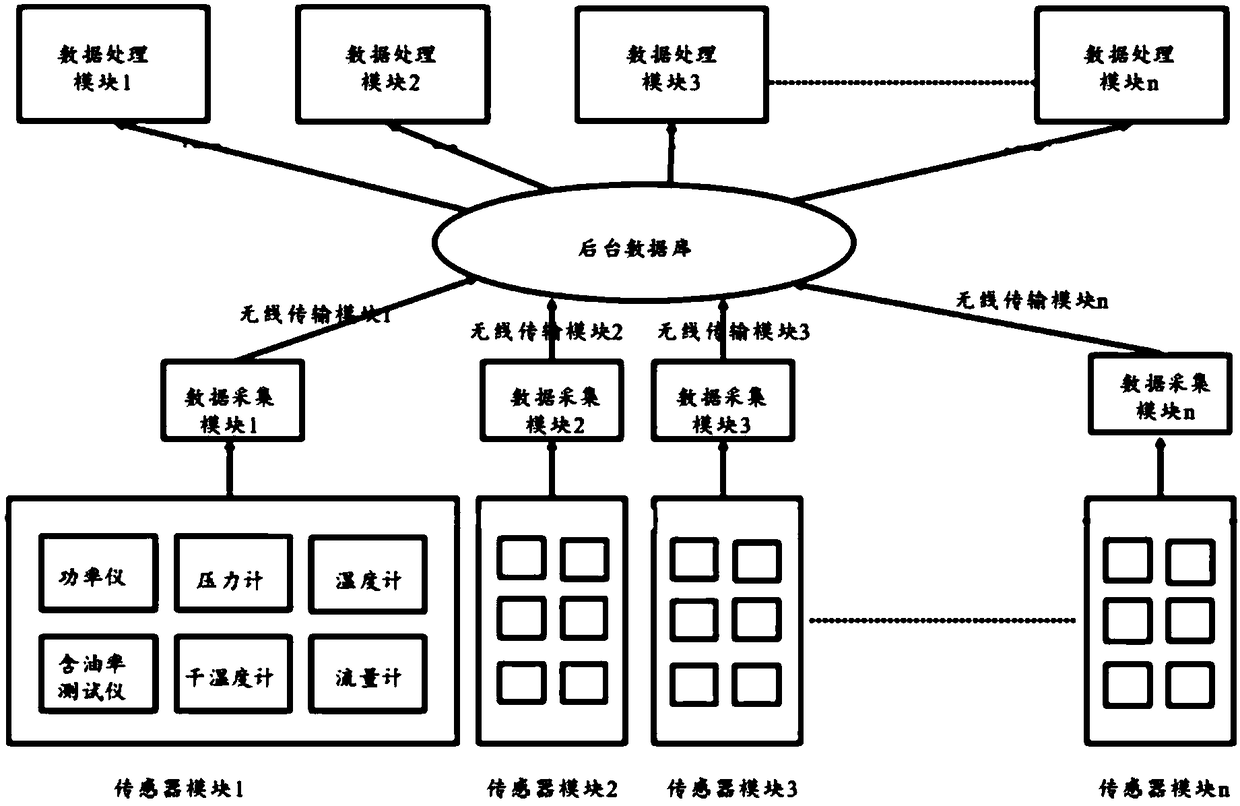

[0046] Such as figure 1 As shown, the embodiment of the present invention provides an air compressor energy efficiency online detection and evaluation system, including a sensor module, a data acquisition module, a wireless transmission module and a data processing module, the sensor module is electrically connected to the data acquisition module, and the The data acquisition module performs information transmission with the data processing module through the wireless transmission module. The sensor module is used to connect with the air compressor to be tested, collect the performance parameter data of the air compressor to be tested online in real time, and send the performance parameter data to the data acquisition module; the data acquisition module includes An analog-to-digital conversion module, configured to convert the analog signal in the received performance parameter data into a digital signal, and send the performance parameter data converted into a digital signal ...

Embodiment 2

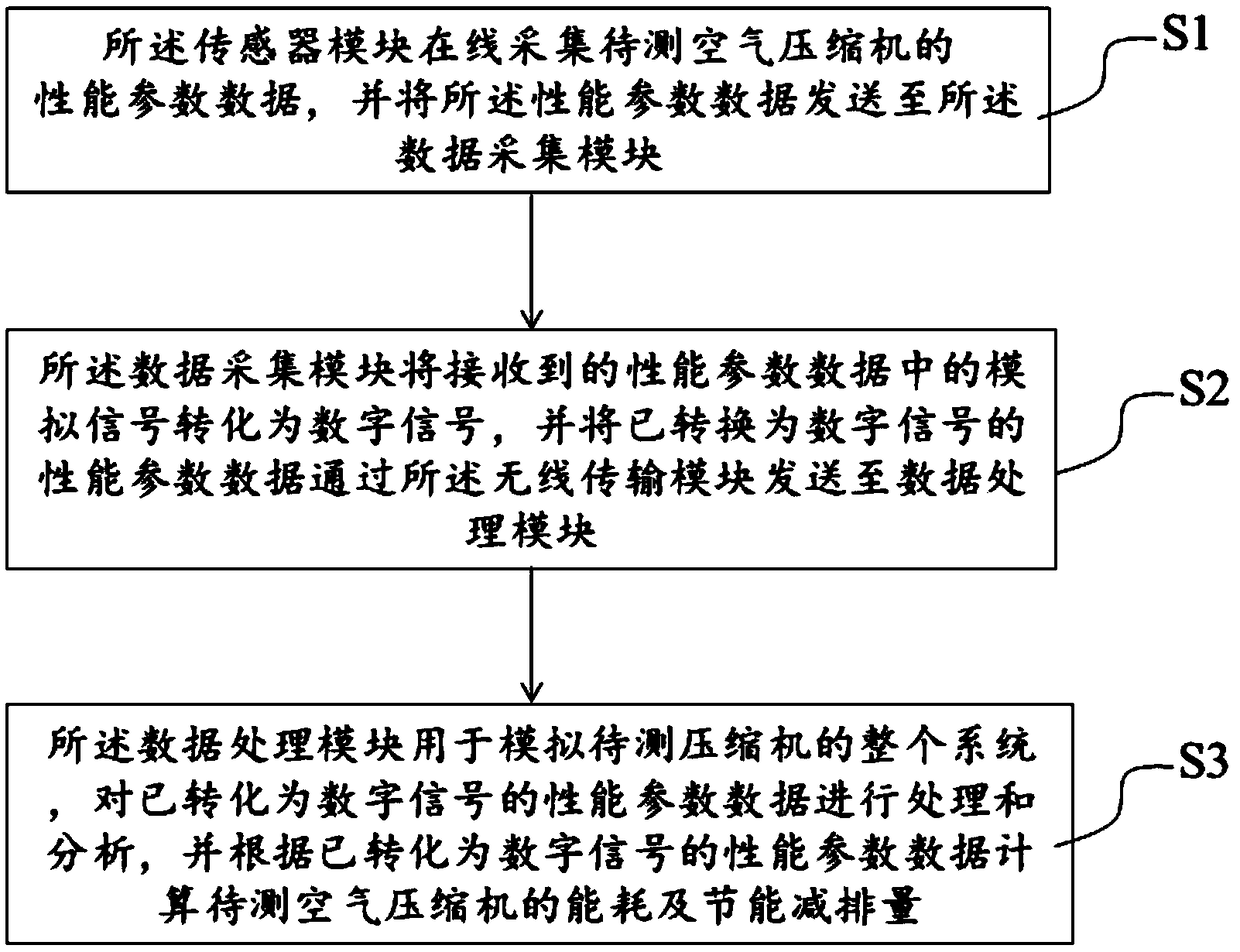

[0064] Such as figure 2 As shown, the embodiment of the present invention provides an air compressor energy efficiency online detection and evaluation method, the method uses the air compressor energy efficiency online detection and energy conservation evaluation system to detect and evaluate the air compressor, and the system includes a sensor module, Wireless transmission module, data acquisition module and data processing module, then described method comprises the following steps:

[0065] When in use, the sensor module and the data acquisition module are first installed on the air compressor to be tested, and then the frequency of data acquisition and the protocol for data upload are set;

[0066] S1. The sensor module collects the performance parameter data of the air compressor to be tested online, and sends the performance parameter data to the data collection module;

[0067] S2. The data acquisition module converts the analog signal in the received performance para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com