Variable gas distribution phase mechanism for opposed-piston engine

A technology of gas distribution timing and opposed pistons, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve problems such as complex mechanisms and unsatisfactory requirements, optimize the ventilation and combustion process, and reduce lubrication and sealing requirements, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

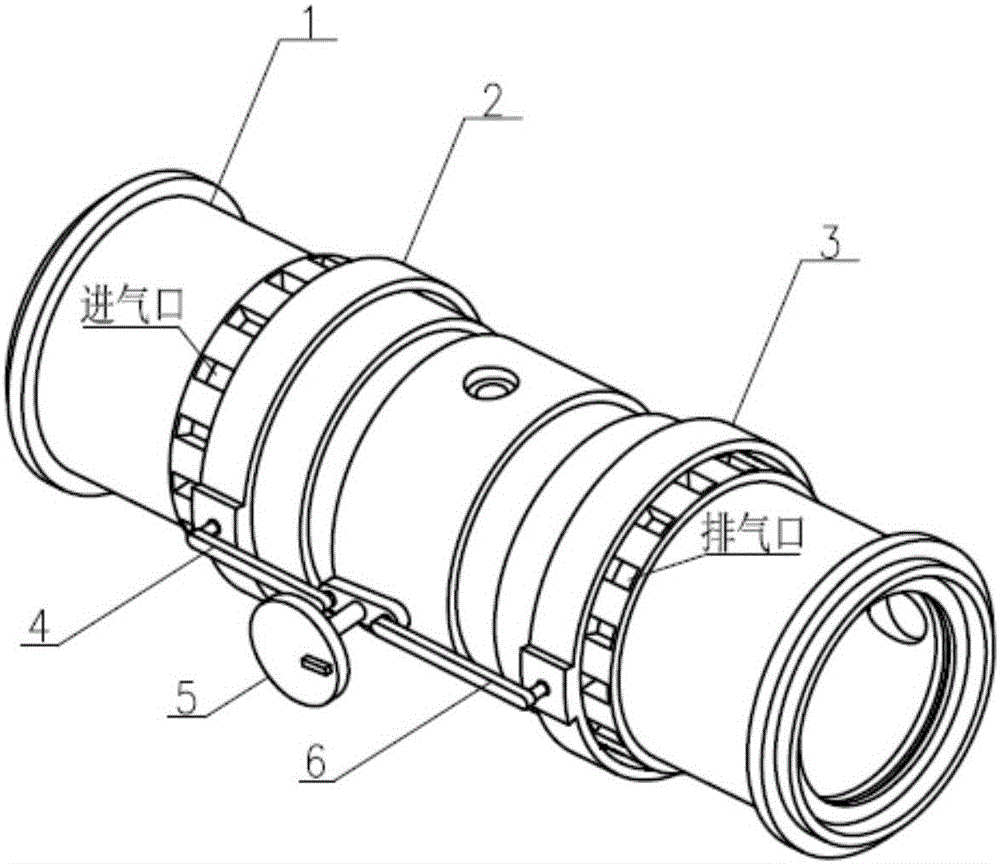

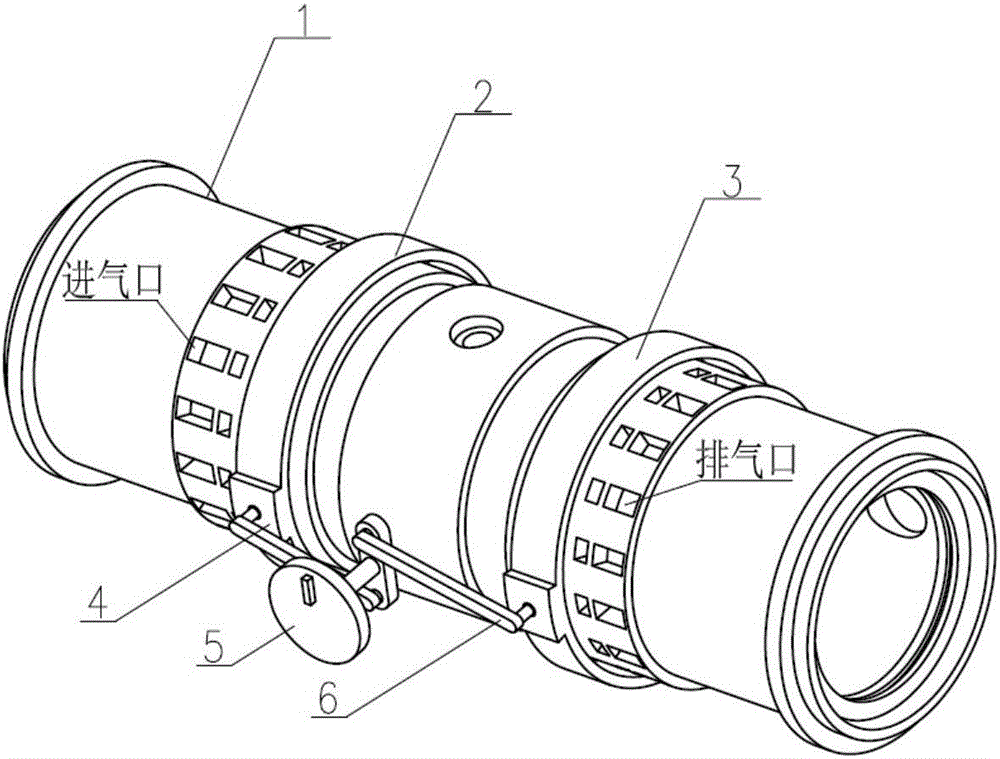

[0021] as attached figure 1 and 2 As shown, the present invention provides a variable valve timing mechanism for an opposed piston engine, which includes a cylinder liner 1, an intake port sliding sleeve 2, an exhaust port sliding sleeve 3, and an air intake connecting rod 4 , adjustable crank 5 and exhaust port connecting rod 6;

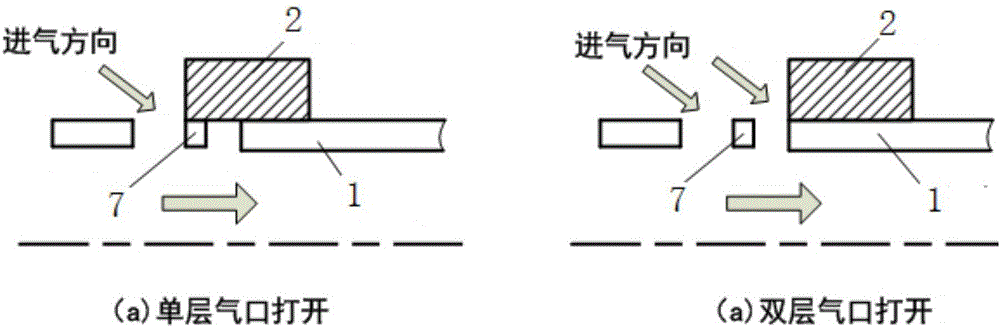

[0022] A group of circumferential air inlets and exhaust ports are arranged axially symmetrically on the cylinder liner 1. In this embodiment, the number of layers of each group of air inlets and exhaust ports along the axial direction is two; The exhaust port is evenly arranged along the circumference of the cylinder liner 1, the shape of the air intake port and the exhaust port is rectangular, and a barrier rib 7 is formed between two adjacent layers of air intake port or exhaust port;

[0023] as attached image 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com