Segment capping module flipping device for subway tunnel

A technology for overturning devices and tunnel segments, applied in tunnels, hoisting devices, hoisting devices, etc., can solve the problems of hidden dangers, labor, and time-consuming operations, and achieve the effects of safe and reliable work, saving manpower, and sensitive turning actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

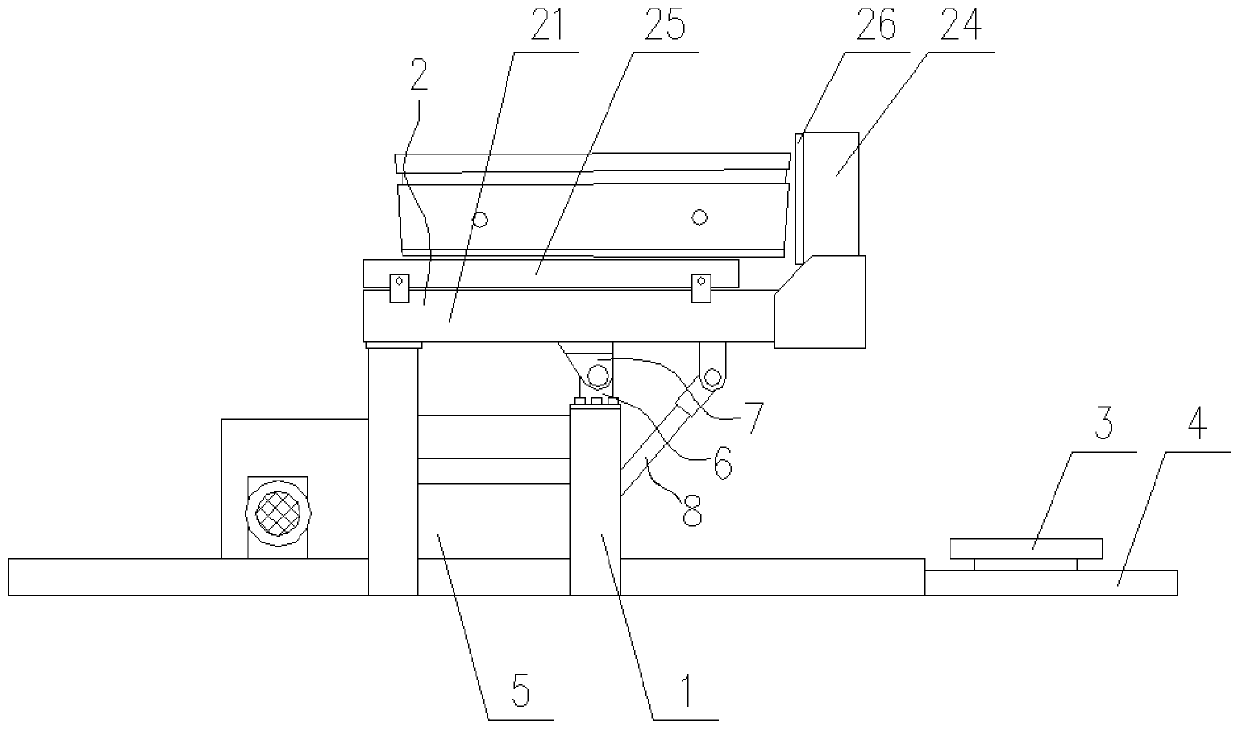

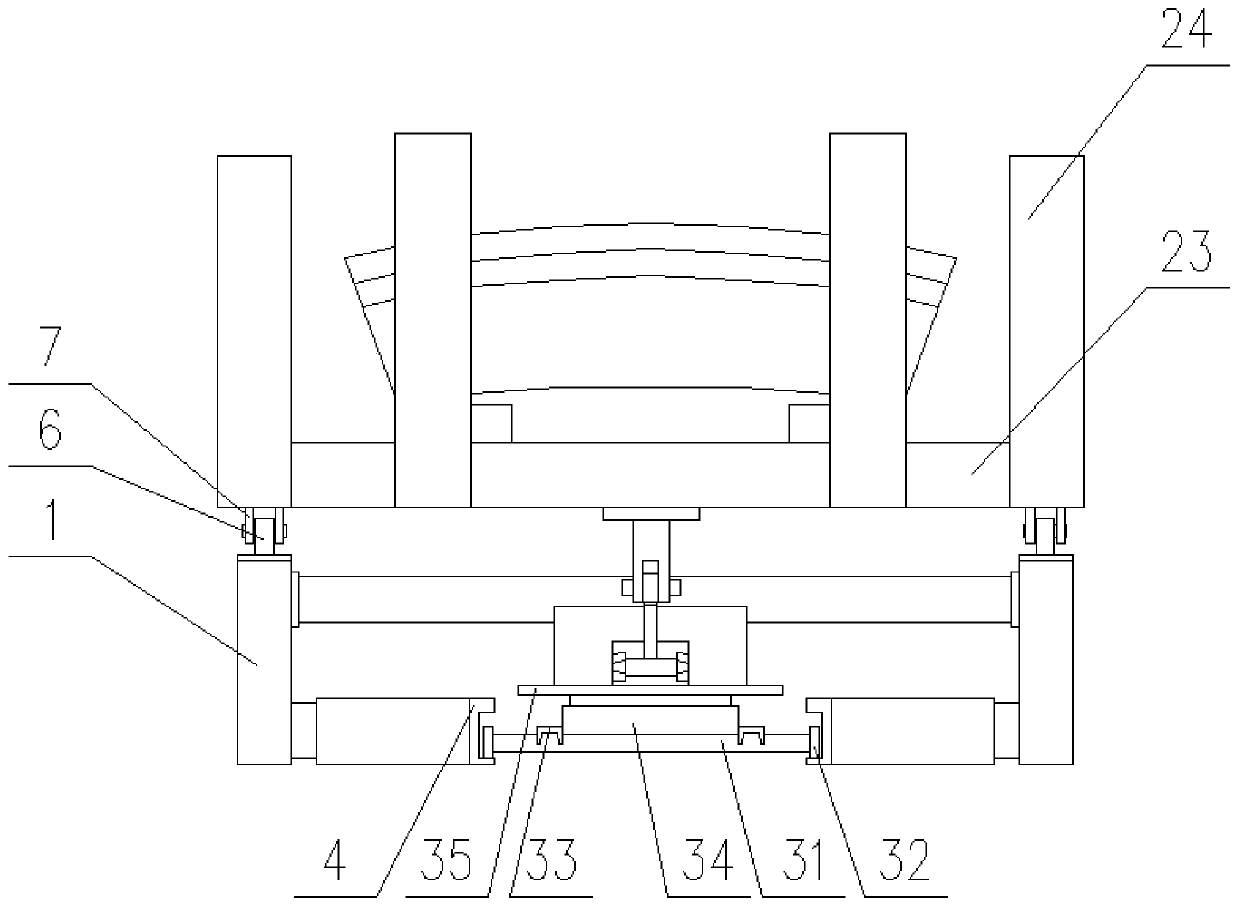

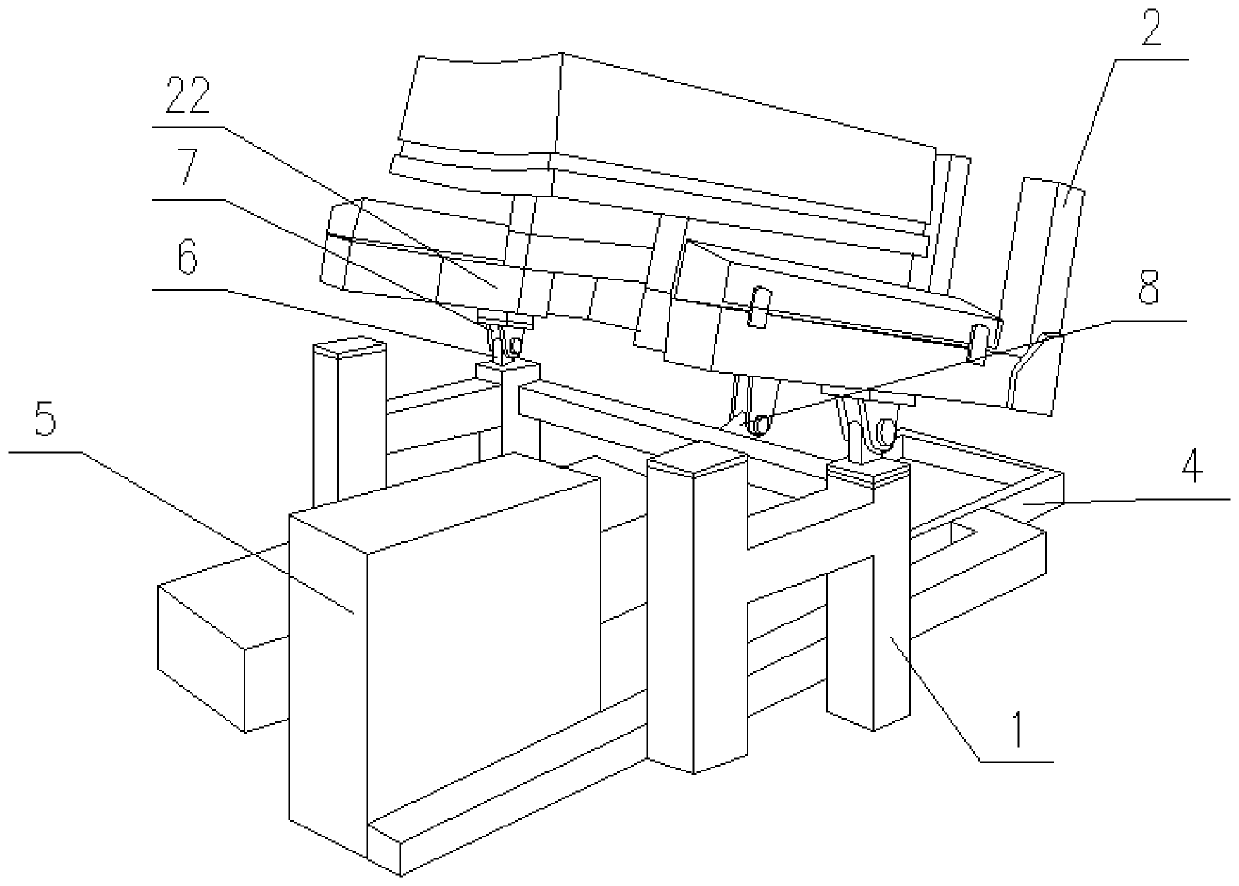

[0022] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, the subway tunnel segment capping module turnover device of this embodiment comprises a lower support frame 1, an upper carrier frame 2, a turnover device 3, a turnover device installation slideway 4 and a drive system 5, and the lower support frame 1 And the upper bearing frame 2 is a frame structure made by welding steel pipes. The upper end of the lower supporting frame 1 is equipped with a fixed seat 6, and the lower end of the upper bearing frame 2 is equipped with a hinged seat 7. The upper bearing frame 2 and the lower The support frame 1 is hingedly installed through the hinged seat 7 and the fixed seat 6. After installation, the upper carrier frame 2 can be turned over relative to the lower support frame 1. The drive system 5 is arranged inside the lower support frame 1. The drive system 5 passes through the connecting rod 8 It is hinged with the lower end of the upper carrie...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 1-Figure 4 Describe this embodiment, the upper bearing frame 2 described in the subway tunnel segment capping module turnover device of this embodiment includes a lateral load beam 21, a lateral auxiliary load beam 22, a connecting beam 23, a vertical load beam 24, a skid 25 and Buffer blocks 26, the transverse bearing beam 21, the transverse auxiliary bearing beam 22 and the connecting beam 23 are welded to form a "mountain"-shaped support body, and the connecting beam 23 is also welded with a plurality of vertical bearing beams 24, and the transverse bearing Skids 25 are installed on the beam 21 and the lateral auxiliary load beam 22 , and a buffer block 26 is installed on the inner working surface of the vertical load beam 24 . In this way, when the installation direction of the upper support frame 2 and the lower support frame 1 is set horizontally, the lateral load beam 21 and the lateral auxiliary load beam 22 ...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 1-Figure 4 Describe this embodiment, the buffer block 26 described in the subway tunnel segment capping module turnover device of this embodiment is a rubber buffer block. In this way, the rubber buffer block can buffer the pressure generated by the gravity of the subway tunnel segment capping module during the turning process, so as to avoid damage to the subway tunnel segment capping module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com