Hinge with damping

A damping and hinge technology, applied in the hinge field, can solve the problems of casualties, worker injuries, easy sticking of damping oil to hands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

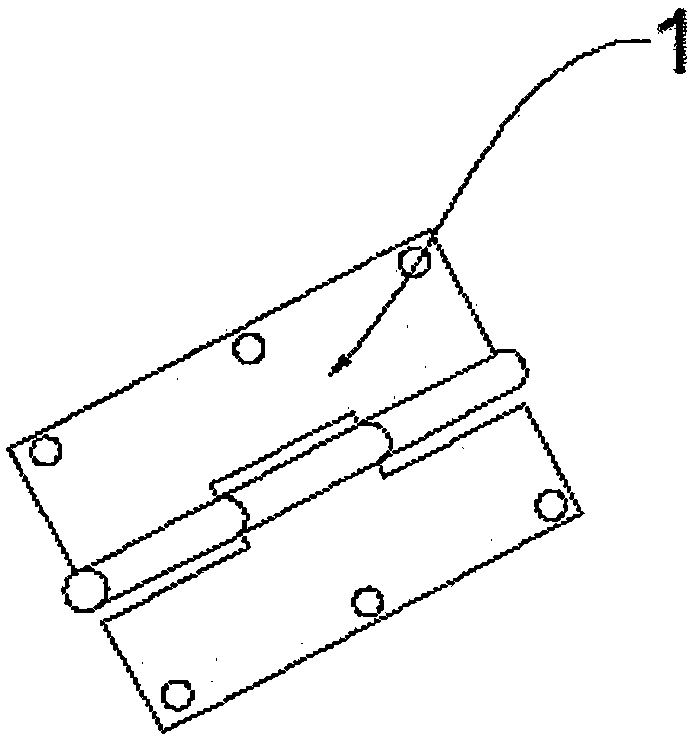

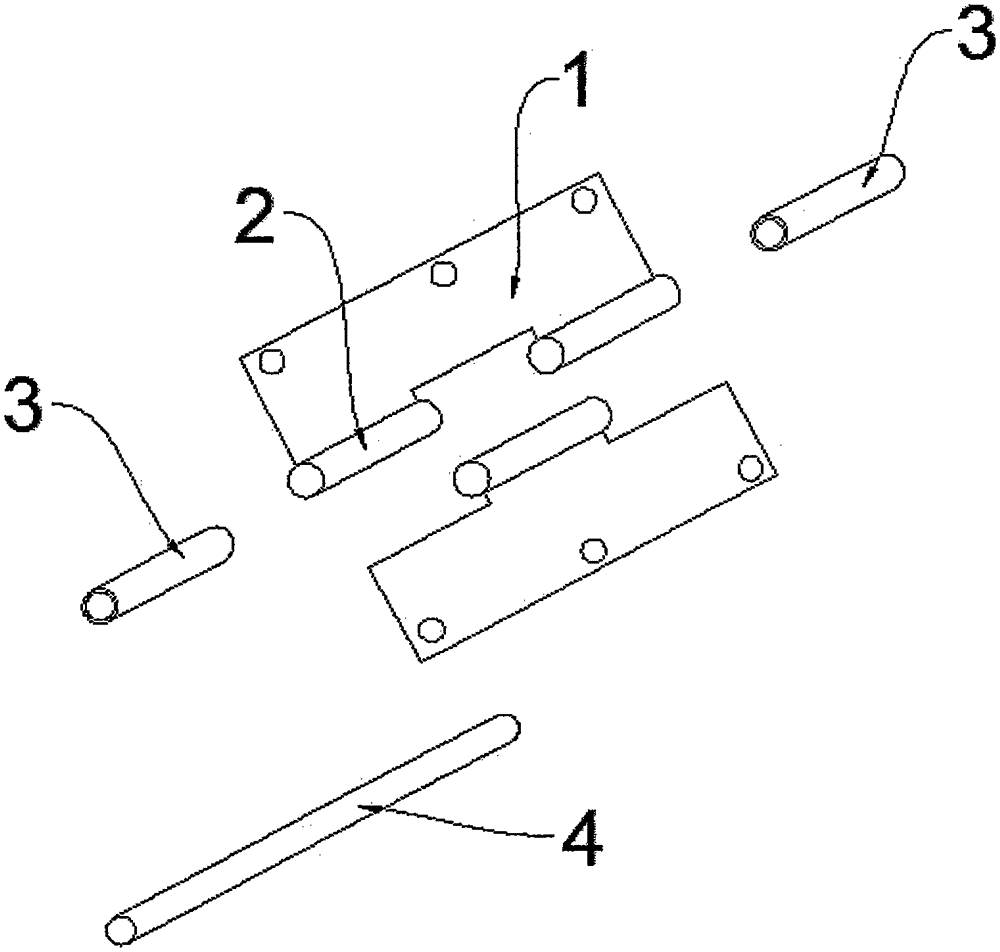

[0012] see figure 1 and figure 2 , the present invention provides a hinge with damping, which includes a connecting mandrel 4 and two blade assemblies 1, the two blade assemblies 1 are connected with a hinge tube 2, and the connecting mandrel passes through the two blade assemblies 1 respectively. The hinge tube 2 on the blade assembly 1, a layer of damping sleeve 3 is also fixed in the hinge tube 2, the connecting mandrel 4 is sleeved in the hinge tube 2 through the damping sleeve 3, and the connecting core The rod 4 is in interference fit with the damping sleeve 3 . The damping sleeve 3 is made of rubber material.

[0013] Due to the use of the damping sleeve 3, there is no need to use damping oil, so the problem of oil leakage is solved. Since the damping sleeve 3 and the connecting mandrel 4 are interference fit, the damping required by the hinge during rotation can be guaranteed. , taking into account the material of the damping sleeve 3, it can ensure that the hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com