Construction method for ship digging-depth dynamic control

A construction method and dynamic control technology, applied in the fields of dredging engineering and cutter suction ship excavation, can solve the problems of increasing the cost of construction parties and reducing economic benefits, and achieve the effects of improving engineering benefits, speeding up construction progress, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

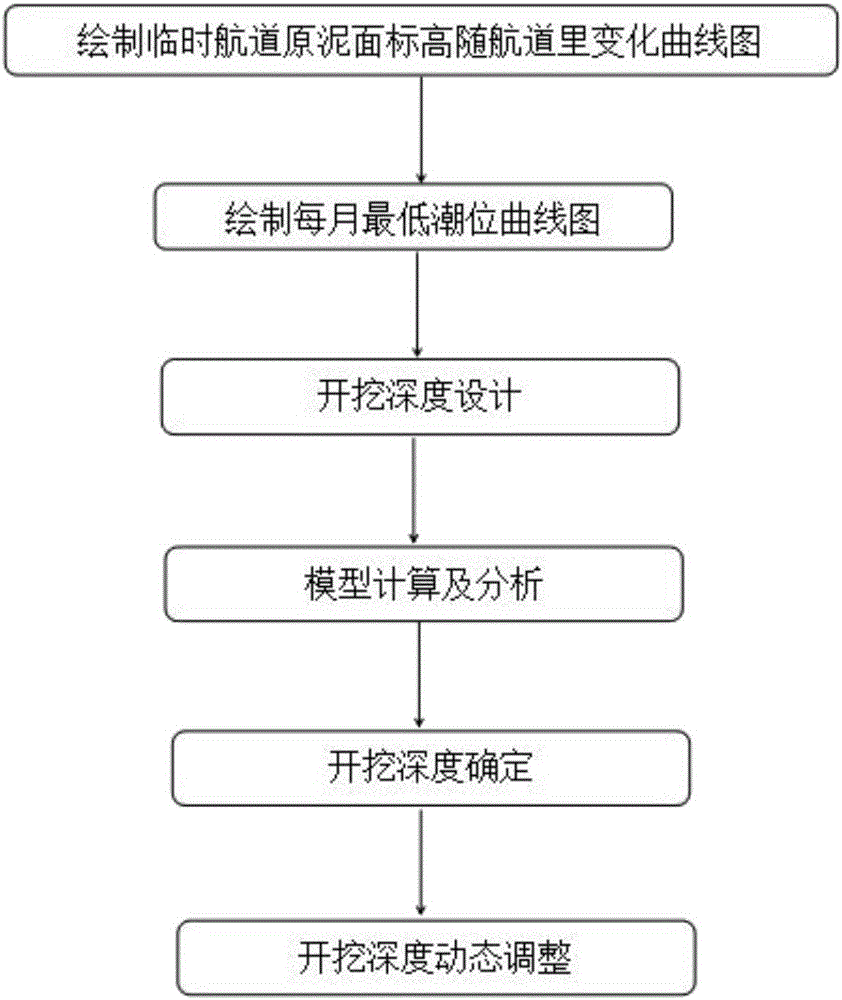

[0030] A construction method for dynamically controlling the excavation depth of a ship, comprising the following steps:

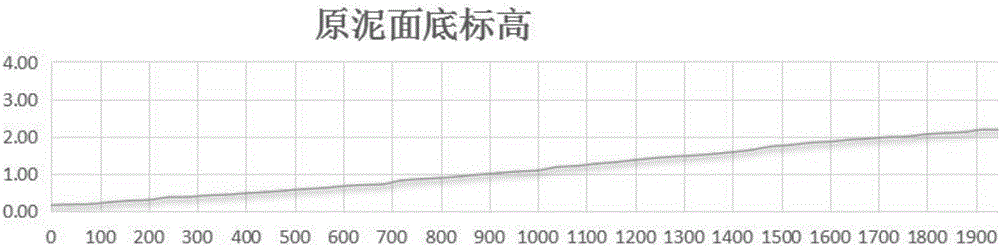

[0031] Step 1, draw the curve of the elevation of the original mud surface of the temporary channel with the mileage of the channel

[0032] Plan the temporary waterway to be constructed, conduct water depth measurement, and analyze the actual change of water depth in the project river section with the mileage of the waterway. The collected information is as follows:

[0033] Channel Mileage Raw mud surface bottom elevation Channel Mileage Raw mud surface bottom elevation Channel Mileage Raw mud surface bottom elevation 0 0.17 520 0.60 1040 1.19 40 0.19 560 0.63 1080 1.22 80 0.20 600 0.68 1120 1.28 120 0.25 640 0.71 1160 1.32 160 0.29 680 0.73 1200 1.38 200 0.31 720 0.83 1240 1.43 240 0.38 760 0.87 1280 1.47 280 0.39 800 0.90 1320 1.50 320 0.43 840 0.94 1360 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com