Assembly type concrete air duct for underground engineering and construction method thereof

An underground engineering and construction method technology, which is applied in water conservancy projects, infrastructure engineering, artificial islands, etc., can solve problems such as difficult repair of air duct roof pouring quality defects, difficult removal of formwork, and difficulty in cross-construction, etc., to achieve reduction Template consumption, increase the rate of prefabrication and assembly, and reduce the effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In the following, the prefabricated concrete air duct for underground engineering and its construction method in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

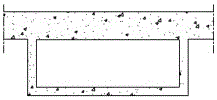

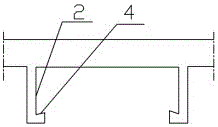

[0052] see Figure 1-Figure 5 , Figure 12, a prefabricated concrete air duct for underground engineering, characterized in that it includes an air duct bottom plate 1, an air duct side wall 2 and an air duct roof 3, and the air duct bottom plate 1 is a plurality of prefabricated concrete air duct floor plates along the direction of the air duct Assembled, a sealing layer is provided between the assembly joints between the bottom plates of the air duct, the side walls 2 of the air duct and the top plate 3 of the air duct are integrally cast from concrete, and the two ends of the bottom plate of the air duct 1 are provided with There is an upper hook, and the inner side of the side wall 2 of the air duct is provided with a lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com