Three-pipe culvert incremental launching construction device and method

A technology of construction device and construction method, which is applied in the direction of earth drilling, road bottom layer, mining equipment, etc., to achieve the effect of reducing the use of human resources, reducing construction land, and making up for the time lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

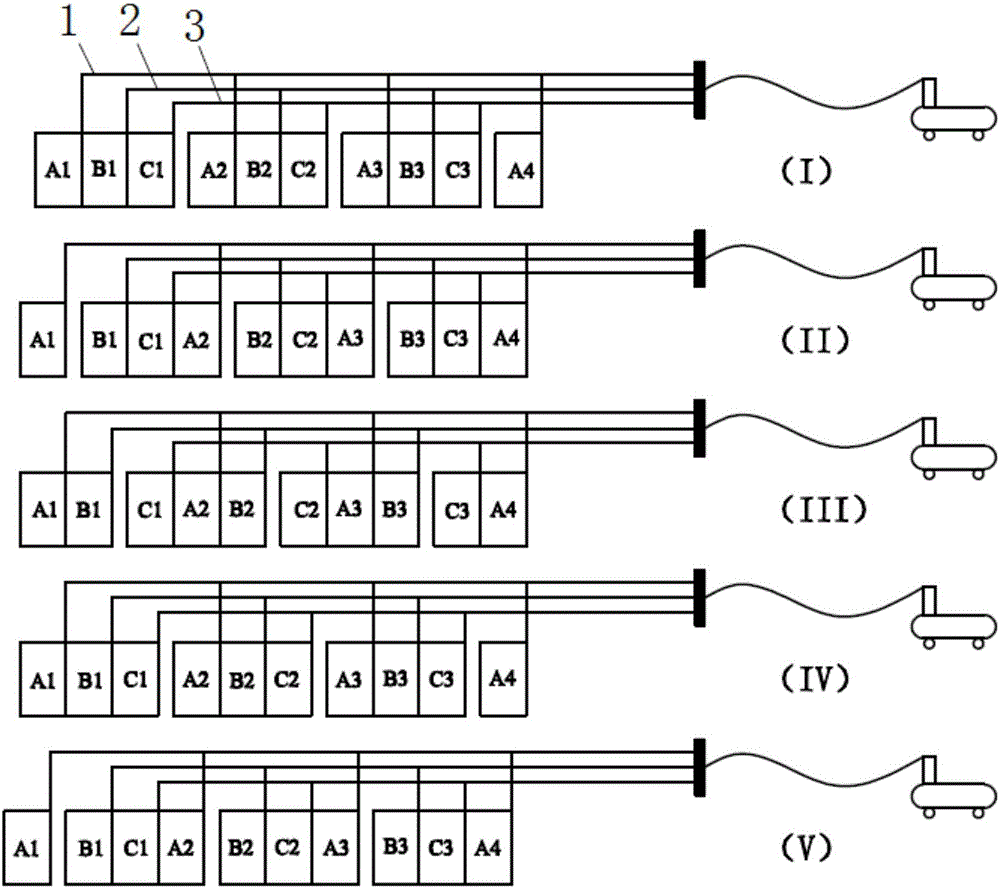

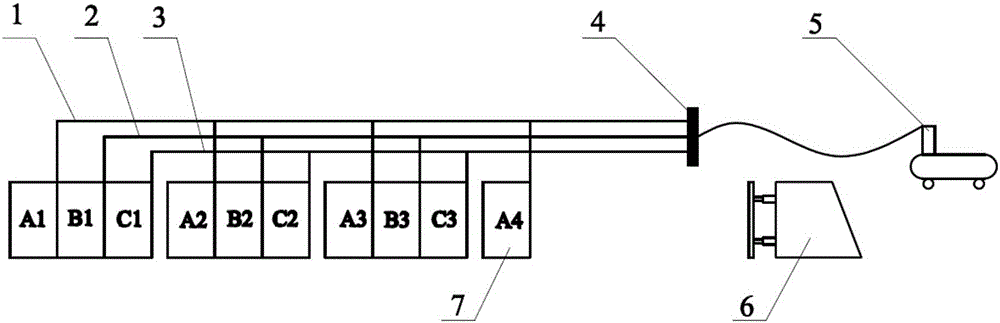

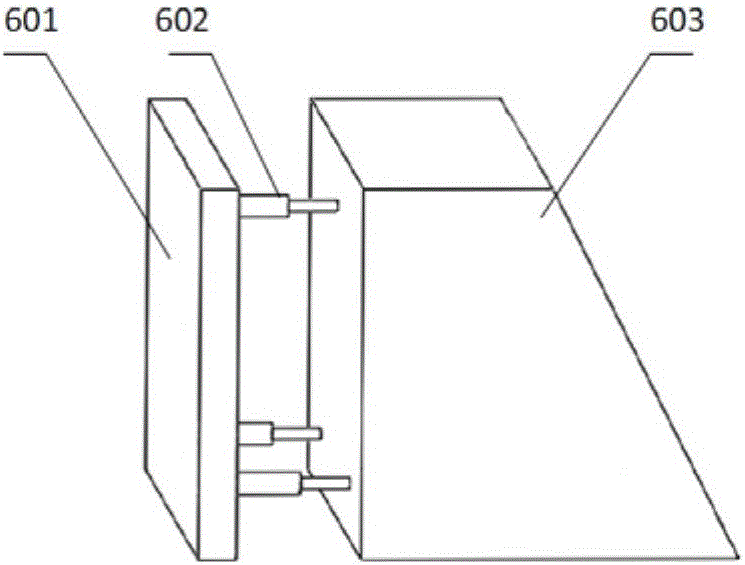

[0066] Such as Figure 1 to Figure 9 As shown, the present invention is a three-pipe method culvert jacking construction device, which is composed of three parts, namely the initial jacking part, the execution part and the power transmission part. Among them, the initial pushing part is composed of the push plate 601, the hydraulic cylinder 602 and the concrete back seat 603 to form the initial pushing device 6; the execution part is composed of the prefabricated lining 701 and the rubber ring 702 to form the lining rubber ring 7; the power transmission part is composed of the air compressor 5 , Control valve 4, a pipe 1, b pipe 2 and c pipe 3.

[0067] In the initial pushing part, one end of the hydraulic cylinder 602 is connected to the concrete back seat 603, and the other end is connected to the push plate 601. The forward and backward m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com