Spraying device with high-speed rail bridge pier automatic maintenance function

A sprinkler equipment and iron bridge pier technology, which is applied in bridge construction, bridge erection/assembly bridge, etc., can solve problems such as low operating efficiency, reduced service life of bridge piers, hidden safety hazards, etc., and achieves light and simple structure, reasonable design, and easy installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

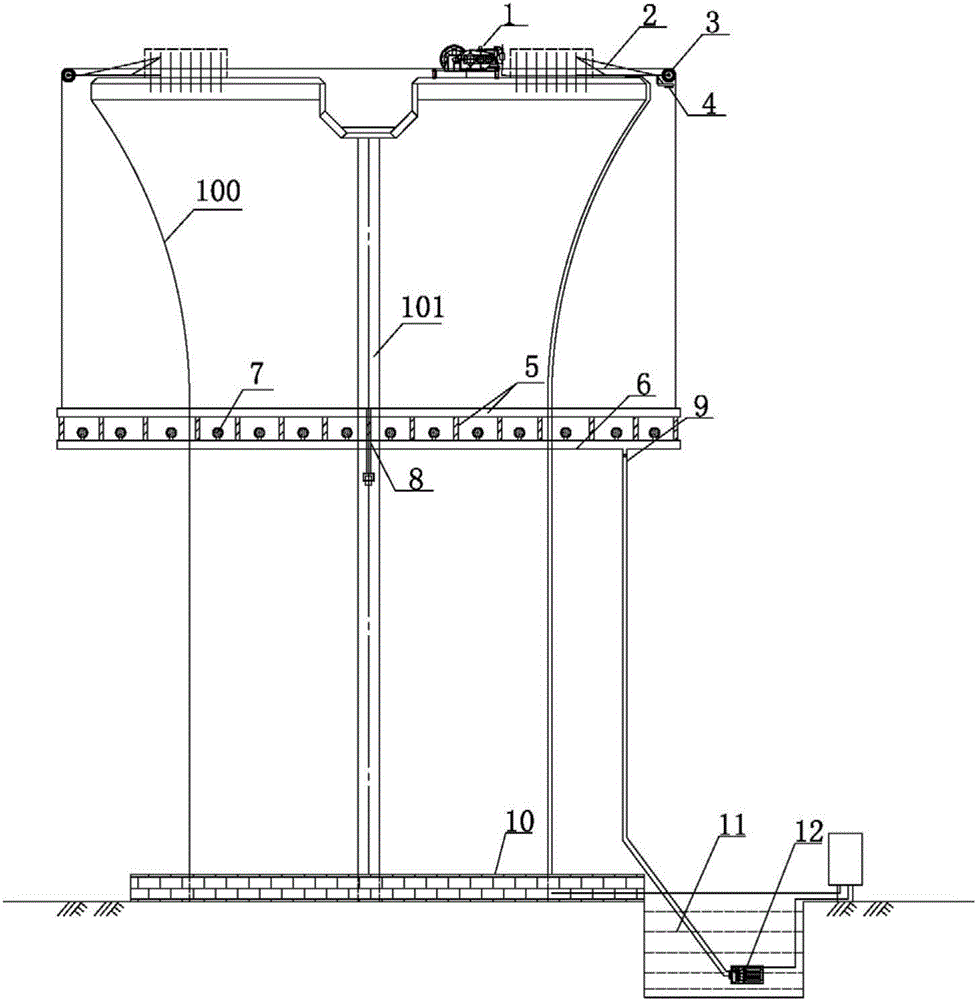

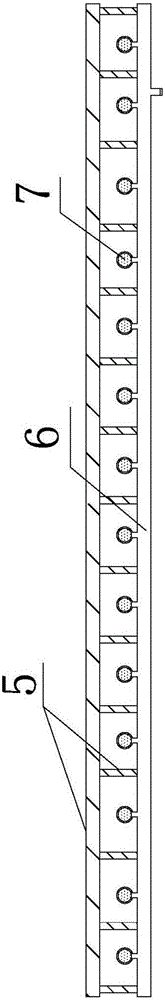

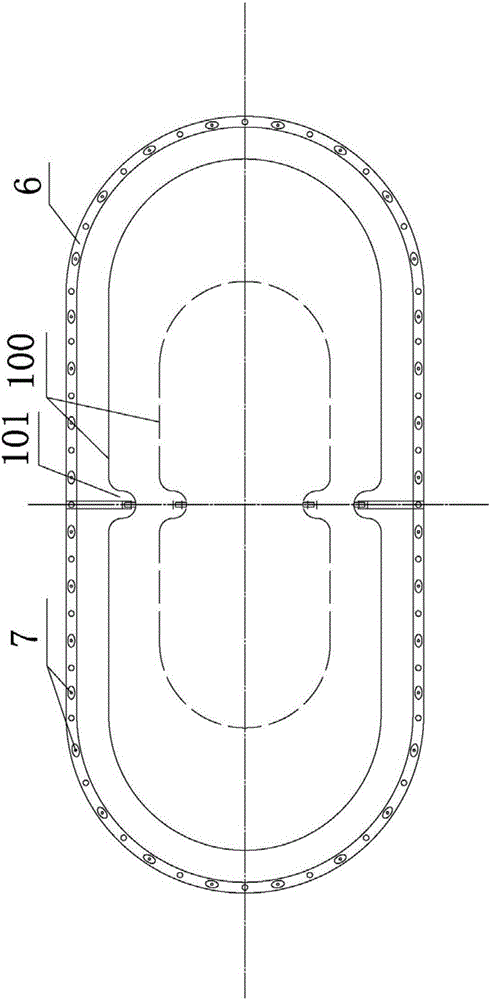

[0015] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a spraying device with the function of automatic maintenance of high-speed rail pier, which is used for spraying high-speed rail pier 100, which consists of hoist 1, steel wire rope 2, roller 3, reinforced steel pipe 5, water supply pipe 6, spray nozzle 7. The spray guiding device 8, the upper water pipe 9, the water ditch 10, the water tank 11 and the water pump 12 are composed of several parts.

[0016] Wherein, a lifting induction control switch 4 is installed on the high-speed rail pier 100 , and the lifting induction control switch 4 is located below the roller 3 .

[0017] The winch 1 is installed on the top of the high-speed railway pier 100 . One end of the steel wire rope 2 is wound on the winch 1, and the other end is connected to the reinforced steel pipe 5, which can lift the reinforced steel pipe 5 up and down. The roller 3 supports the wire rope 2 .

[0018] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com