Production method of fine-denier porous super-bright trilobal nylon 6 filament

A production method, trilobal technology, applied in filament/thread forming, clustering of newly extruded filaments, single-component polyamide artificial filaments, etc., to achieve broad market prospects and economic benefits, fabrics feel thick, Good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

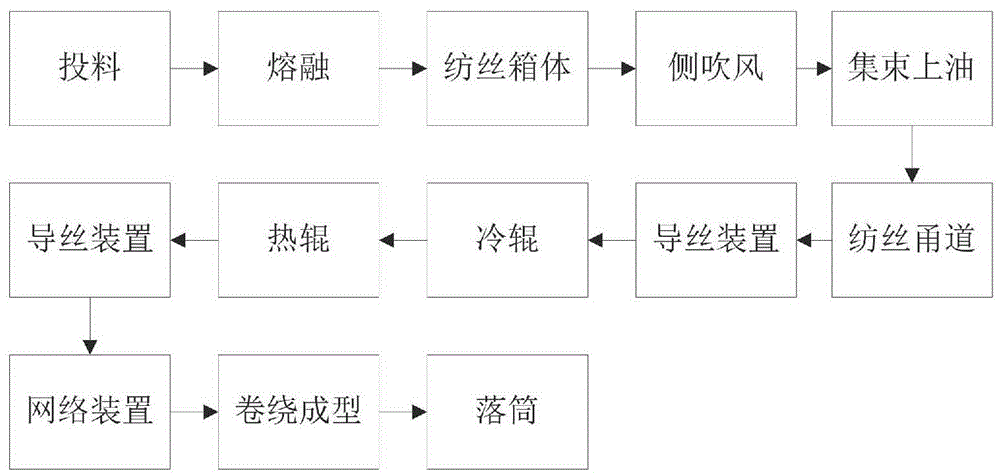

[0031] The production method of trilobal glossy nylon 6 filament with specification 30D / 34F, monofilament fineness 0.89D, profile degree 20% is as follows, process flow reference figure 1 ;

[0032] Spinning-grade nylon 6 slices with a relative viscosity of 2.48±0.02 and a moisture content of ≤500ppm are put into the silo, heated and melted by the screw extruder and sent to the spinning box through the melt distribution pipe; the temperature range of each zone of the screw extruder 242, 247, 250, 252, 252°C;

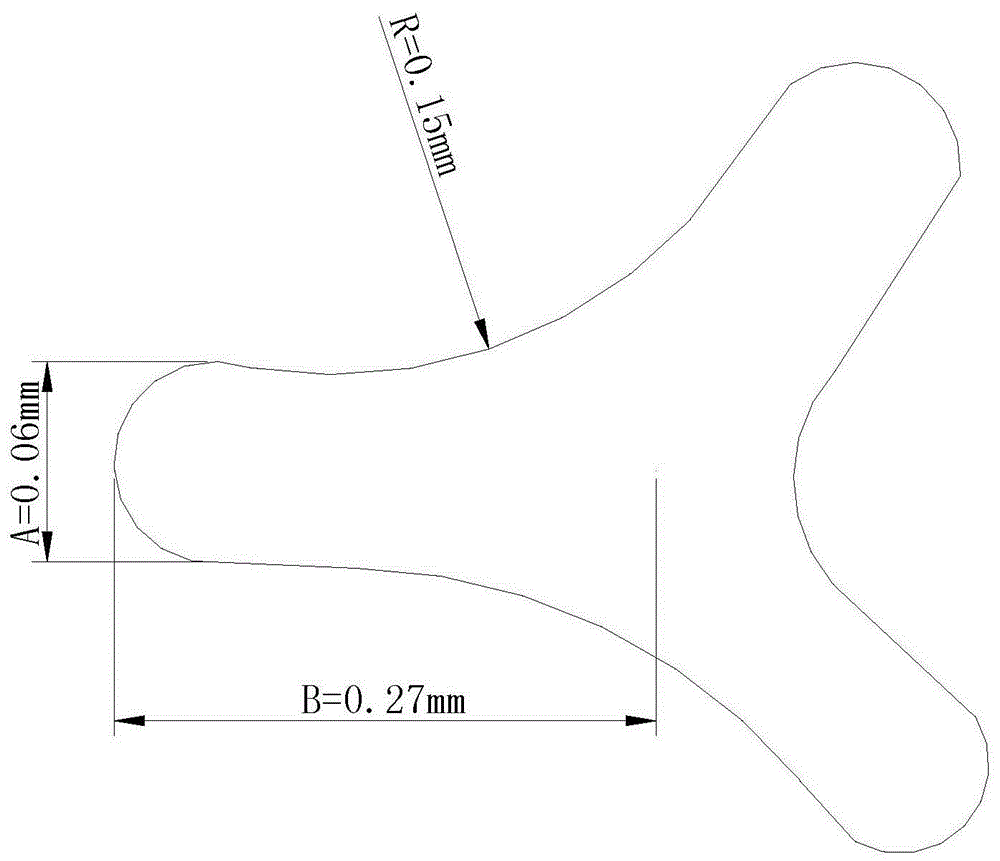

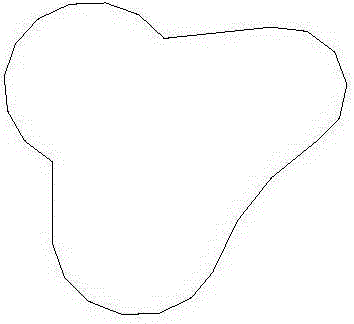

[0033] The melt enters the spinning assembly in the spinning box, and is sprayed out through the spinneret hole of the three-lobed section. The inner diameter of the spinneret plate is 70mm, and the arrangement of the spinneret holes is "circular", and the hole specification is the same as "capillary hole". As shown in "Characteristics"; the spinning assembly is equipped with five layers of filter screens, a layer of non-woven fabric and a certain proportion of mixed co...

Embodiment 2

[0040] The production method of trilobal glossy nylon 6 filament with specification 40D / 34F, monofilament fineness 1.18D, and profile degree 30% is as follows, and the process flow refers to figure 1 ;

[0041] Spinning-grade nylon 6 slices with a relative viscosity of 2.48±0.02 and a moisture content of ≤500ppm are put into the silo, heated and melted by the screw extruder and sent to the spinning box through the melt distribution pipe; the temperature range of each zone of the screw extruder 242, 247, 250, 252, 252°C;

[0042] The melt enters the spinning assembly in the spinning box, and is sprayed out through the spinneret hole of the three-lobed section. The inner diameter of the spinneret plate is 70mm, and the arrangement of the spinneret holes is "circular", and the hole specification is the same as "capillary hole". As shown in "Characteristics"; the assembly is equipped with five layers of filter screens, a layer of non-woven fabric and a certain proportion of mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com