Preparation method for metal nano particle-doping flexible self-supporting graphene thin film

A metal nanoparticle, graphene film technology, applied in graphene, nanocarbon, nanotechnology and other directions, can solve the problems of less preparation research, many operation steps, complicated methods, etc., and achieves low process requirements and good flexibility. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the flexible self-supporting graphene film doped with metal nanoparticles of the present invention comprises the following steps:

[0021] (1) According to the improved Hummers method (ACS Nano 4 (8): 4806 (2010), Improved synthesis of graphene oxide), with graphite as raw material, the preparation concentration is the graphene oxide aqueous solution of 0.2~3mg / ml; The metal salt aqueous solution The concentration is 0.1-20wt.%.

[0022] (2) Mix the graphene oxide solution and the metal salt solution evenly, and the mass ratio of the metal salt to the graphene oxide is 0.1˜10:1. Titrating the mixed solution on the plasma-surface-treated solid substrate, and further vacuum-drying at 50-100 degrees Celsius for 0.5-5 hours to obtain a graphene oxide film;

[0023] (3) Put the thin film on the solid substrate into the ascorbic acid aqueous solution with a concentration of 0.1-10wt.%, and then react at 60-120 degrees Celsius for 1-5 hours to obtain...

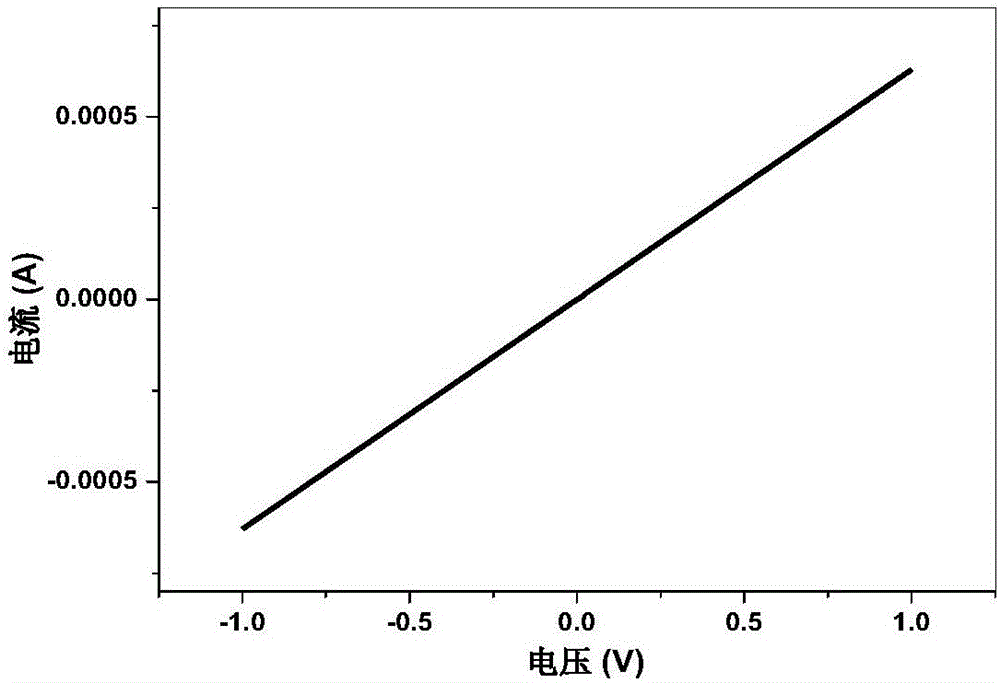

Embodiment 1

[0025] Example 1: Preparation of flexible self-supporting graphene conductive film internally doped with nickel nanoparticles

[0026] (1) According to the improved Hummers method (documentation ACS Nano 4(8):4806(2010), Improvedsynthesis of graphene oxide), using graphite as raw material, the graphene oxide aqueous solution whose concentration is 0.5mg / ml is prepared; the configuration concentration is 2mg / ml of nickel acetate aqueous solution;

[0027] (2) Mix the graphene oxide solution and the nickel acetate solution evenly, and the mass ratio of the nickel acetate to the graphene oxide is 0.2:1. The mixed solution was titrated on the plasma surface treated solid substrate, and further vacuum dried at 60 degrees Celsius for 0.5h to obtain a graphene oxide film;

[0028] (3) Putting the graphene oxide film on the glass substrate into the ascorbic acid aqueous solution with a concentration of 0.5wt.%, and reacting for 1h at 95 degrees Celsius to obtain a self-supporting gr...

Embodiment 2

[0030] Example 2: Preparation of flexible self-supporting graphene conductive film doped with gold rice particles on the surface

[0031] (1) According to the improved Hummers method (ACS Nano 4 (8): 4806 (2010), Improved synthesis of graphene oxide), graphite is used as raw material to prepare a graphene oxide aqueous solution with a concentration of 2 mg / ml; the configuration concentration is 4 mg / ml Chlorauric acid aqueous solution;

[0032] (2) uniformly titrate the graphene oxide aqueous solution on the glass substrate treated by plasma surface, and further vacuum-dry 1h at 75 degrees Celsius to obtain the graphene oxide film; further titrate the chloroauric acid solution on the graphene oxide film, chlorine The mass ratio of gold acid and graphene oxide is 2:1. and dried under vacuum at 60 °C for 2 h.

[0033] (3) Put the film on the substrate into a 1.5wt.% ascorbic acid aqueous solution, and react at 95 degrees Celsius for 1 hour to obtain a self-supporting graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com