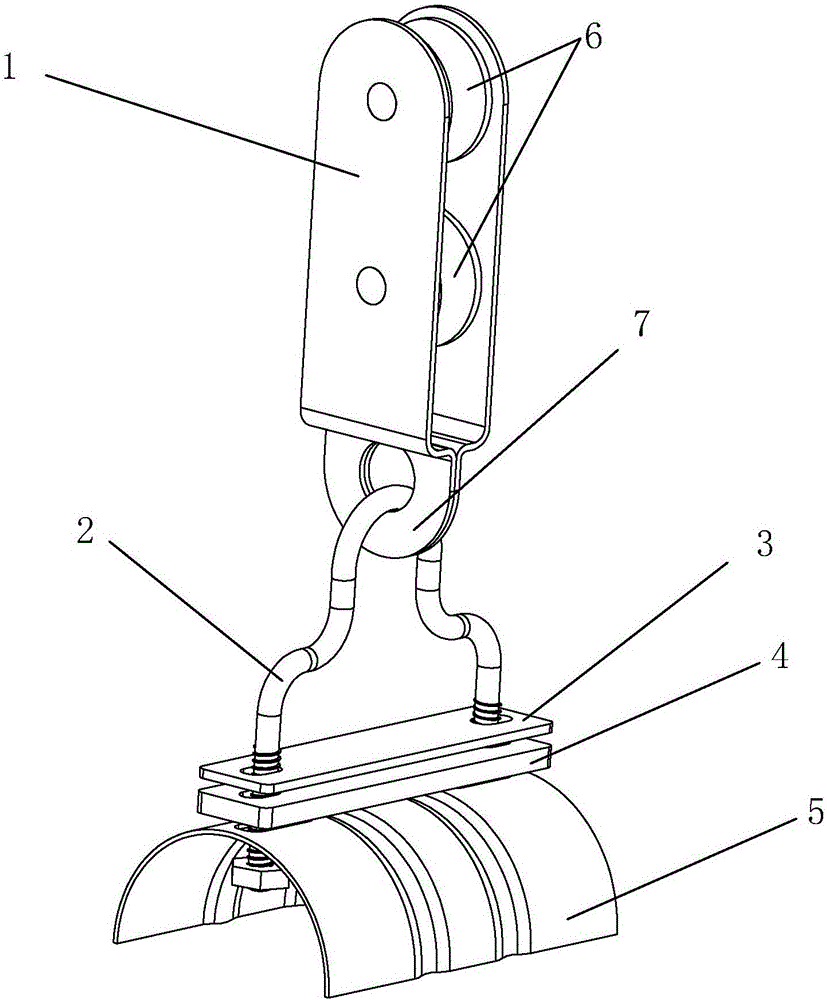

Formula of special stainless steel for crane cable coaster and preparation method thereof

A crane and stainless steel technology, which is applied in the field of stainless steel formulation and its preparation, can solve the problems of crane cable block rusting, reduce the possibility of crane cable block rusting, etc., and achieve slow corrosion speed, high yield strength and elongation, and good The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

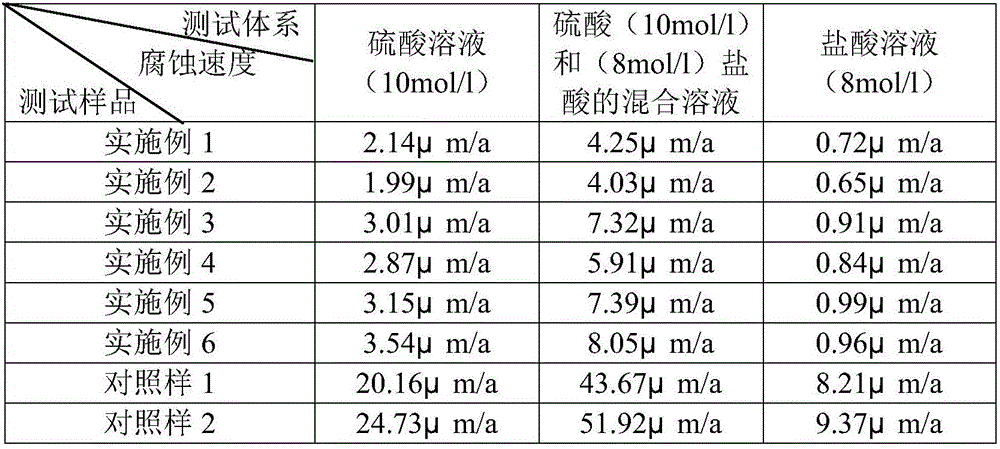

Examples

Embodiment 1

[0057] Example 1: A stainless steel specially used for crane cable pulleys is prepared by the following method: take the following formula as the raw material, cold-roll the raw material, and then solution treatment, the temperature of the solution treatment is 1075°C, and the solution time 15min; its formula is (in weight percentage):

[0058] C: 0.01%;

[0059] Si: 0.35%;

[0060] Mn: 0.03%;

[0061] S: 0.01%;

[0062] P: 0.01%;

[0063] Cr: 22.00%;

[0064] Ni: 9.00%;

[0065] Cu: 0.40%;

[0066] N: 0.02%;

[0067] Ti: 0.02%;

[0068] Fe: 68.15%.

Embodiment 2

[0069] Example 2: A stainless steel dedicated for crane cable trolleys. The difference from Example 1 is that its formula is (in weight percentage):

[0070] C: 0.01%;

[0071] Si: 0.40%;

[0072] Mn: 0.04%;

[0073] S: 0.01%;

[0074] P: 0.01%;

[0075] Cr: 23.00%;

[0076] Ni: 8.00%;

[0077] Cu: 0.35%;

[0078] N: 0.02%;

[0079] Ti: 0.03%;

[0080] Fe: 68.13%.

Embodiment 3

[0081] Example 3: A stainless steel specially used for crane cable trolleys. The difference from Example 1 is that its formula is (in weight percentage):

[0082] C: 0.02%;

[0083] Si: 0.75%;

[0084] Mn: 0.05%;

[0085] S: 0.01%;

[0086] P: 0.02%;

[0087] Cr: 21.00%;

[0088] Ni: 9.50%;

[0089] Cu: 0.45%;

[0090] N: 0.03%;

[0091] Ti: 0.04%;

[0092] Fe: 67.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com