Brown sugar plum wine and preparing method thereof

A technology of green plum wine and brown sugar, applied in the field of winemaking, can solve the problems of single taste, weak aroma of green plum, long production cycle, etc., and achieve the effect of rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

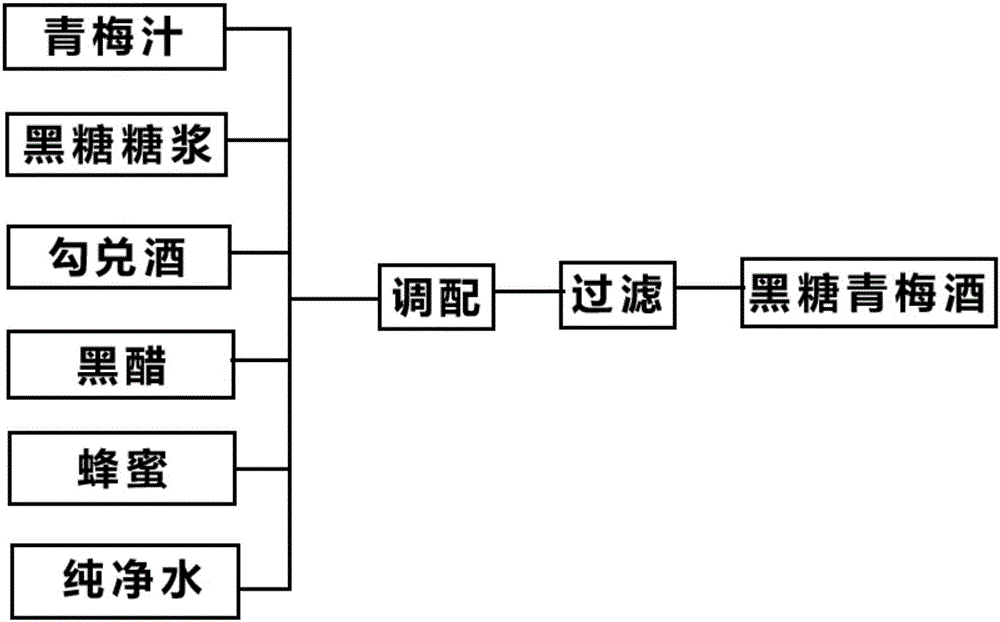

[0048] Please see attached figure 1 Shown, a kind of preparation method of dark sugar plum wine, this method at least comprises the following steps:

[0049] Step 1: Prepare greengage juice.

[0050] Step 2: Prepare Brown Sugar Syrup.

[0051] Step 3: Prepare the blended wine.

[0052] Step 4: Prepare Japanese Black Vinegar.

[0053] Step 5: Blend brown sugar plum wine.

[0054] Step 6: Strain the black sugar plum wine.

[0055] Please see attached figure 2 As shown, in said step 1, the following sub-steps are also included:

[0056] Step 1.1: Wash 8-9 mature greengages, remove stems and cores, blanch and sterilize, and beat them into pulp.

[0057] Step 1.2: Add pectinase for fermentation, and let stand at 12-28 degrees Celsius for 7 days.

[0058] Step 1.3: Heat the green plum juice at high temperature to achieve the effect of removing enzymes.

[0059] Step 1.4: After the greengage juice is roughly filtered with diatomaceous earth, it is separated again using a hi...

Embodiment

[0080] A black sugar plum wine, comprising the following raw materials in parts by weight: 7 parts of green plum juice, 6 parts of brown sugar, 3 parts of maltose, 1 part of white granulated sugar, 27 parts of distilled rice wine, 1 part of dark rum, 51 parts of purified water, 1 part Japanese black vinegar, 3 parts honey.

[0081] A preparation method of black sugar plum wine, comprising the following steps:

[0082] Step 1: Preparation of greengage juice: wash 8-9 mature greengages, remove stems and cores, blanch and sterilize, make pulp, add pectinase for fermentation, and let stand at 12-28 degrees Celsius for 7 days , and then heat the greengage juice at high temperature to achieve the effect of removing enzymes. After coarsely filtering the greengage juice with diatomaceous earth, use a high-speed centrifuge to separate it again, and finally use a stainless steel filter membrane for ultrafiltration to obtain greengage with high clarity and no precipitation juice and set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com