A kind of technique for rapidly extracting ketone from Tongkat Ali

A wide hysterone and process technology, which is applied in the field of extraction and separation of plant active components, can solve the problems of insufficient extraction of active components, long raw material processing time, unsuitable for large-scale production, etc., and achieves shortening extraction time, preventing oxidation, and improving utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

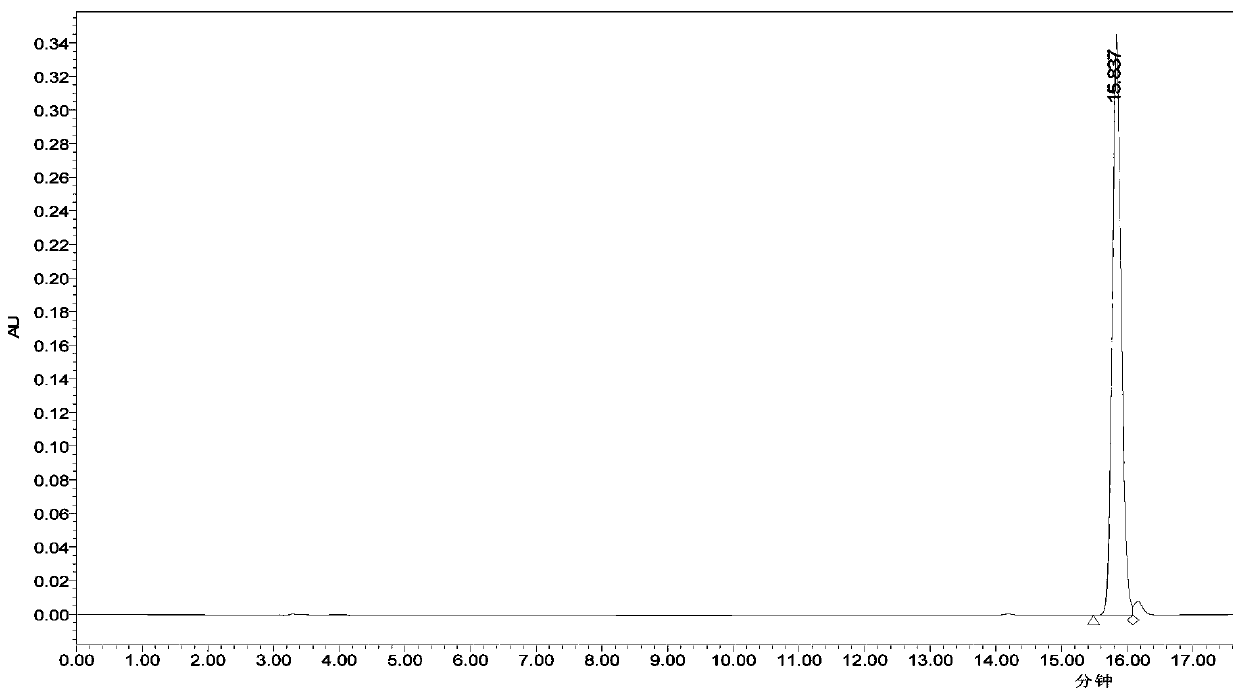

Image

Examples

Embodiment 1

[0023] Take 4kg of Tongkat Ali powder and crush it into a subcritical extraction kettle. Use 60% ethanol solvent to perform subcritical extraction at 90°C for 60 minutes. The mass ratio of Tongkat Ali powder to ethanol solvent is 1:5. Ethanol extract of Tongkat Ali; the ethanol extract of Tongkat Ali is cooled to room temperature, and concentrated at 60°C under a vacuum of -0.1MPa. The volume after concentration is 20% of the ethanol extract of Tongkat Ali, and the concentration is Liquid; decanter centrifugation of the obtained concentrated liquid at 3000r / min to obtain the centrifugal supernatant; the obtained supernatant was applied to the HPD100 macroporous resin column for gradient elution (first use 10% ethanol to elute 1BV, Then use 30% ethanol to elute 2.5BV, and finally use 60% ethanol to elute 4BV) to obtain the eluate; concentrate the obtained eluate to 1 / 500 of the volume of the eluate to obtain The elution concentrate is added with alcohol 0.5 times the volume of t...

Embodiment 2

[0025] Take 4kg of Tongkat Ali powder and crush it into a subcritical extraction kettle. Use ethanol solvent with a concentration of 70% by volume for subcritical extraction at 100°C for 45 minutes. The mass ratio of Tongkat Ali powder to ethanol solvent is 1:8. To obtain the Tongkat Ali ethanol extract; cool the Tongkat Ali ethanol extract to room temperature, and concentrate at 70°C and a vacuum of -0.08MPa, and the concentrated volume is 15% of the Tongkat Ali ethanol extract, Obtain the concentrated liquid; decanter the obtained concentrated liquid at 3200r / min to obtain the centrifugal supernatant; apply the obtained supernatant to the HPD100 macroporous resin column for gradient elution (first elution with 10% ethanol volume fraction 1BV, then use 30% ethanol to elute 2.5BV, and finally use 70% ethanol to elute 3.5BV) to obtain the eluent; concentrate the obtained eluent to 1 / of the eluent volume 800, to obtain the elution concentrate, add 0.8 times the volume of the elu...

Embodiment 3

[0027] Take 4kg of Tongkat Ali powder and crush it and put it into a subcritical extraction kettle. Use an ethanol solvent with a concentration of 80% by volume to perform subcritical extraction at 120°C for 30 minutes. The mass ratio of Tongkat Ali powder to ethanol solvent is 1:10. Obtain the Tongkat Ali ethanol extract; cool the Tongkat Ali ethanol extract to room temperature and concentrate at 80°C under a vacuum of -0.07MPa, and the concentrated volume is 10% of the Tongkat Ali ethanol extract, Obtain the concentrated solution; decanter the obtained concentrated solution at 3500r / min to obtain the centrifugal supernatant; apply the obtained supernatant to the HPD100 macroporous resin column for gradient elution (first elution with 10% ethanol volume fraction 1BV, then use 30% ethanol to elute 2.5BV, and finally use 80% ethanol to elute 3BV) to obtain the eluate; concentrate the obtained eluate to 1 / 1000 of the volume of the eluate , To obtain the elution concentrate, add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com