Novel aromatic amine light emitting material and application of novel aromatic amine light emitting material

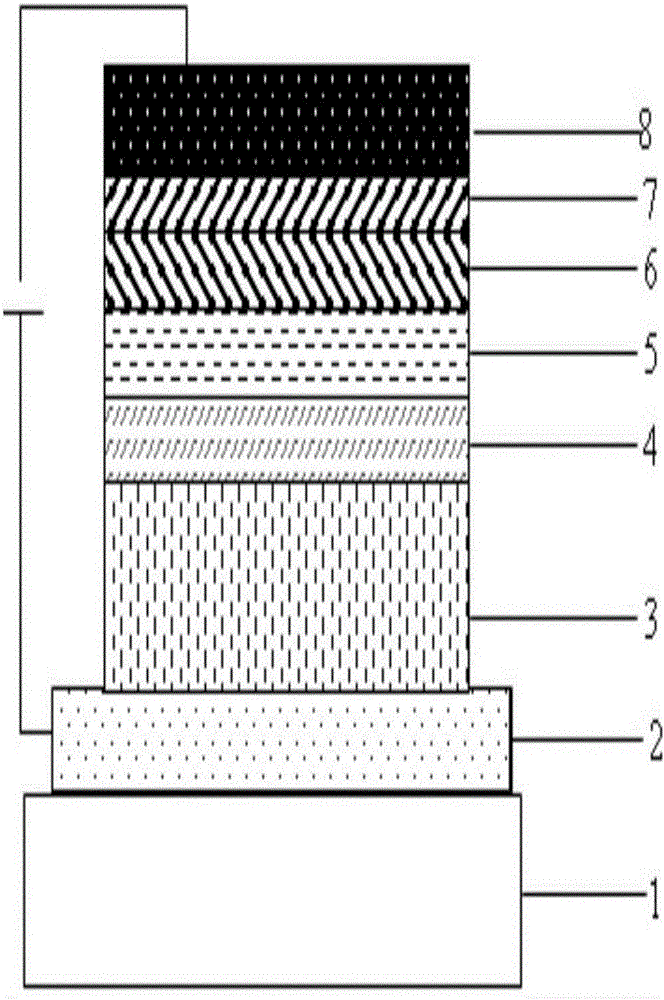

A technology of aromatic amines and light-emitting materials, applied in the field of semiconductors, can solve different problems, and achieve the effects of long service life, improved power efficiency and external quantum efficiency, and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

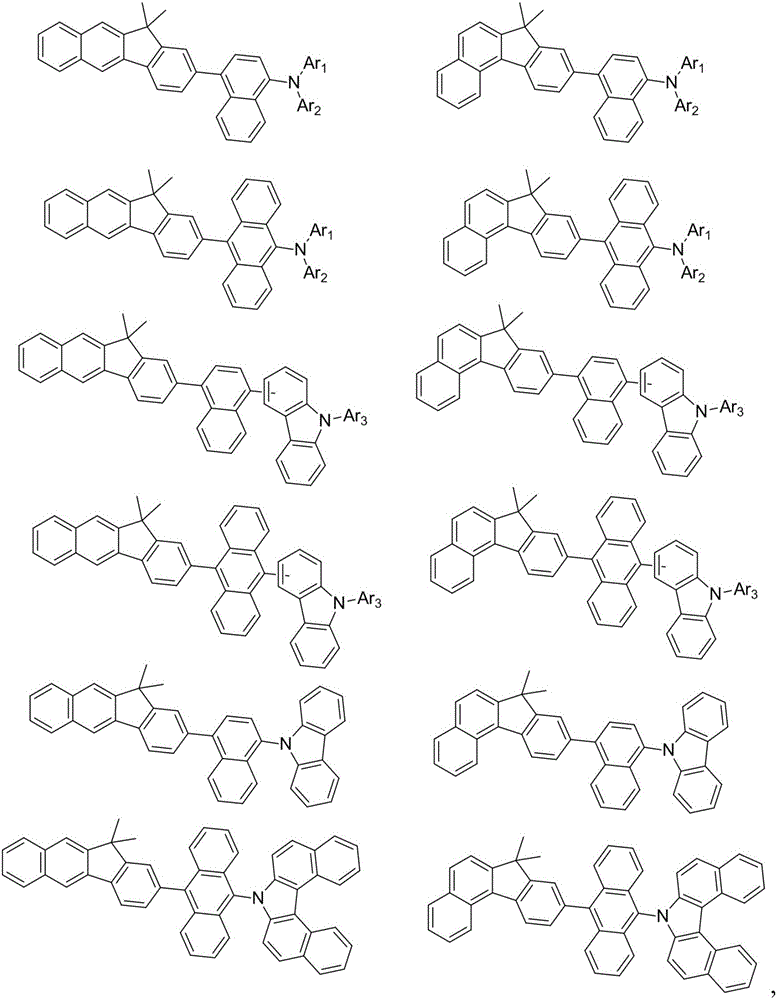

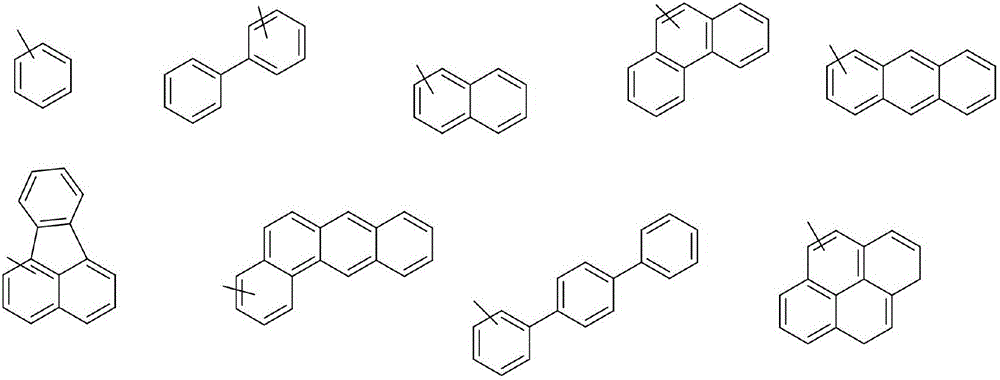

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: the synthesis of compound I

[0056]

[0057] Under the protection of nitrogen, add 35g of compound D, 11.86g of diphenylamine, 10.1g of sodium tert-butoxide, 0.16g of palladium acetate, 0.4g of tricyclohexylphosphine, and 300g of toluene into a 500mL three-necked flask, start stirring, and heat in an oil bath. After the temperature rises to 105-110°C, heat preservation begins. After the reaction is detected by TLC, 50g of industrial hydrochloric acid and 50g of water are added to the reaction solution, separated, washed with water, desolventized, and recrystallized with toluene to obtain product D, which is dried and weighed at about 26.8 g, yield 65.1%.

[0058] Elemental analysis structure: Molecular formula is C 45 h 33 N; HPLC-MS: 587.39; Actual molecular weight: 587.75.

Embodiment 2

[0059] Embodiment 2: the synthesis of compound J

[0060]

[0061] Under nitrogen protection, add 26g of compound F, 9.80g of diphenylamine, 8.34g of sodium tert-butoxide, 0.13g of palladium acetate, 0.33g of tricyclohexylphosphine, and 300g of toluene into a 500mL three-neck flask, start stirring, and heat with an oil bath. After the temperature was raised to 105-110°C, heat preservation was started. After the reaction was detected by TLC, 50g of industrial hydrochloric acid and 50g of water were added to the reaction liquid, layered, washed with water, solvent removed, and recrystallized with toluene to obtain product J, which was dried and weighed about 23.6 g, yield 75.9%.

[0062] Elemental analysis structure: Molecular formula is C 41 h 31 N; HPLC-MS: 537.48; actual molecular weight: 537.69.

Embodiment 3

[0063] Embodiment 3: the synthesis of compound K

[0064]

[0065] Under nitrogen protection, add 33g of compound D, 11.05g of carbazole, 9.6g of sodium tert-butoxide, 0.15g of palladium acetate, 0.37g of tricyclohexylphosphine, and 320g of toluene into a 500mL three-necked flask, start stirring, and heat with an oil bath. After the temperature rises to 105-110°C, heat preservation begins. After the reaction is detected by TLC, add 45g of industrial hydrochloric acid and 45g of water to the reaction solution, separate layers, wash with water, remove the solvent, and recrystallize with toluene to obtain product K, which is dried and weighed at about 28.5 g, yield 73.6%

[0066] Elemental analysis structure: Molecular formula is C 45 h 31 N; HPLC-MS: 585.37; actual molecular weight: 585.73.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com