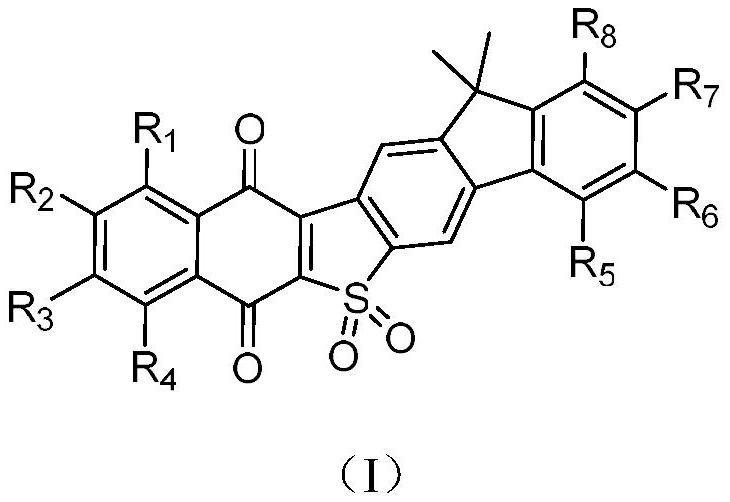

Organic material and application thereof

An organic material, electromechanical technology, applied in the field of organic electroluminescence display, to achieve the effects of high film formation stability, good carrier mobility, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to the preparation method provided by the present invention, those skilled in the art can use known common means to realize, such as further selecting suitable catalysts, solvents, determining suitable reaction temperature, time, material ratio, etc., the present invention is not particularly limited to this . Unless otherwise specified, the solvents, catalysts, bases and other raw materials used in the preparation process can be synthesized through open commercial channels or methods known in the art.

[0033] Synthesis of Intermediates M1~M16

[0034] Synthesis of Intermediates M1 and M2

[0035]

[0036] The synthetic route is as follows:

[0037]

[0038] The specific operation steps are:

[0039] (1) Add dichloromethane (200mL) and aluminum trichloride (29.3g, 0.22mol) to a 2L three-necked flask equipped with mechanical stirring, start stirring, and add 4-bromophthalic anhydride (22.6g, 0.1mol) in dichloromethane (150mL), stirred at room tempera...

Embodiment 1

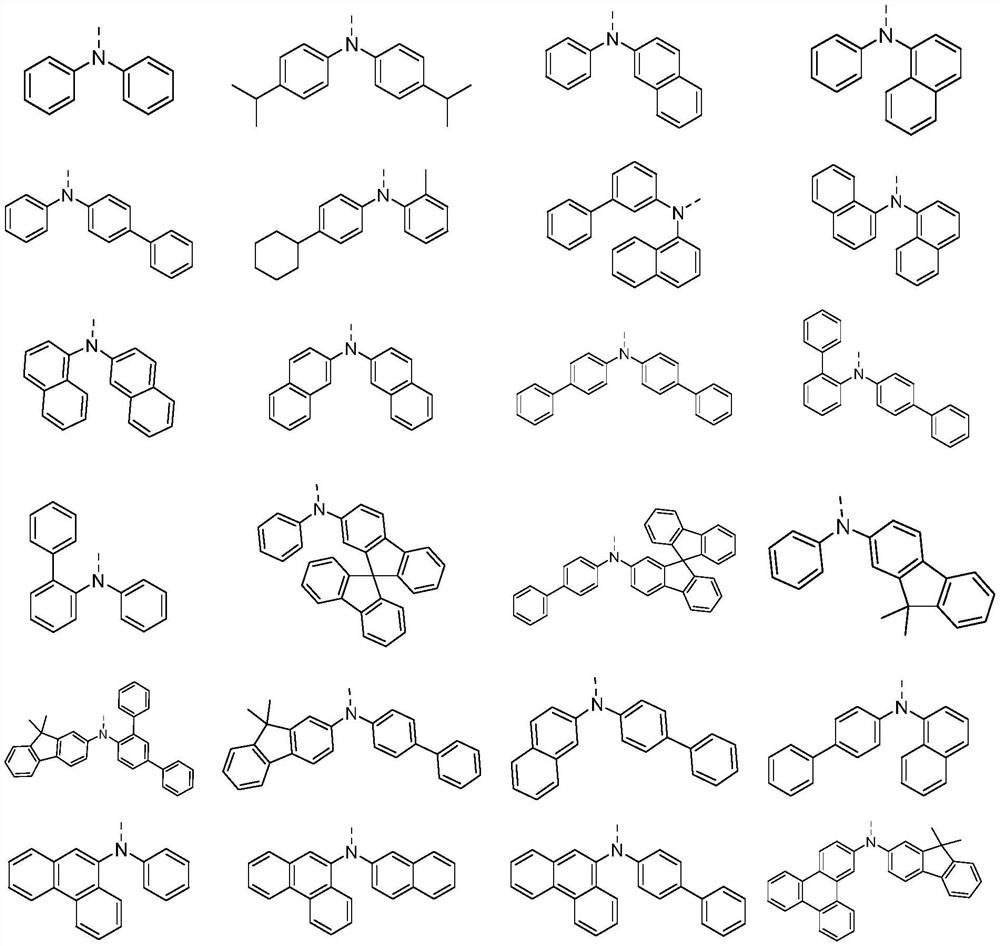

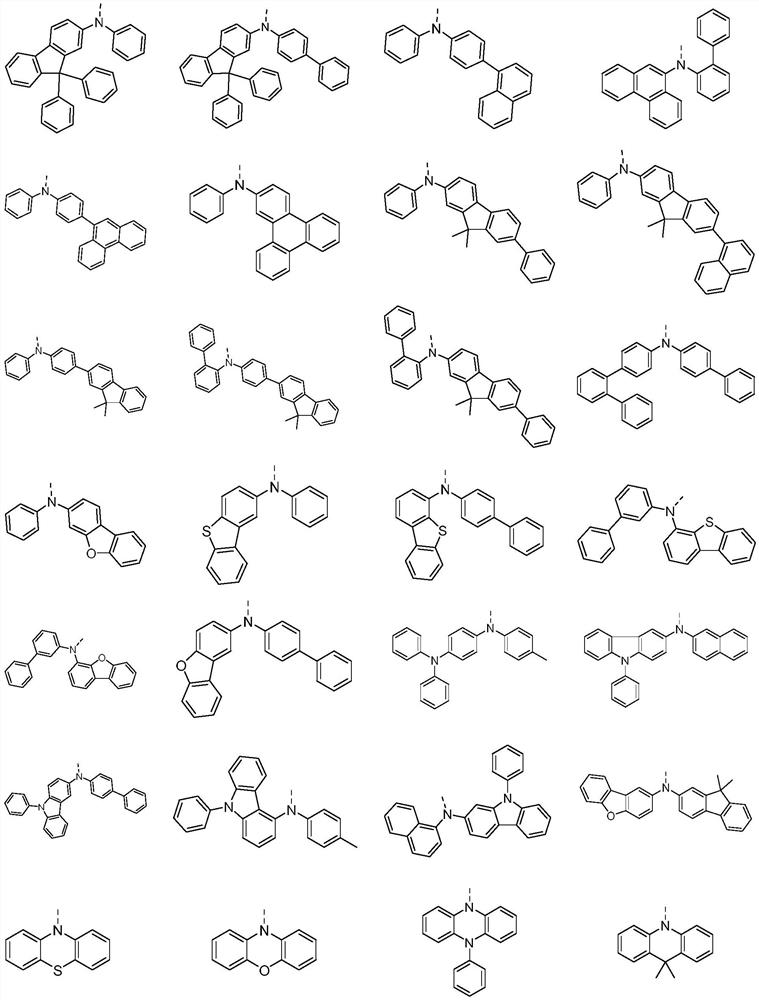

[0086] The synthesis of embodiment 1 compound 1-3

[0087]

[0088] The synthetic route is as follows:

[0089]

[0090] A 2L three-neck flask equipped with a magnetic stirrer was added in sequence with sodium tert-butoxide (28.8 g, 0.3 mol), N-phenylnaphthalene-2-amine (21.9 g, 0.1 mol) and 400 ml of toluene after nitrogen replacement. After nitrogen replacement again, (0.4 g, 2 mmol) tri-tert-butylphosphine and (0.92 g, 1 mmol) tribenzylideneacetone dipalladium were added in sequence. After the addition was complete, the temperature was raised to 85°C. Start to drop a solution consisting of (49.0 g, 0.1 mol) M1 and 100 ml of toluene, heat to reflux (110-120° C.) for 4 hours, and the reaction ends. Adjust to neutral, separate the organic phase, extract, dry, perform column chromatography, and spin dry the solvent to obtain 54.1 g of light yellow solid I-3 with a yield of about 86%.

[0091] Product MS (m / e): 629.17; Elemental analysis (C 41 h 27 NO 4 S): theoretic...

Embodiment 2

[0092] The synthesis of embodiment 2 compound 1-4

[0093]

[0094] The synthetic route is as follows:

[0095]

[0096] Replace M1 with M2, N-phenylnaphthalene-1-amine instead of N-phenylnaphthalene-2-amine, select a suitable material ratio, other raw materials and steps are the same as the synthesis method of Example 1, and obtain 57.3g light yellow Solid I-4, yield about 82%.

[0097] Product MS (m / e): 629.17; Elemental analysis (C 41 h 27 NO 4 S): theoretical value C: 78.20%, H: 4.32%, N: 2.22%; measured value C: 78.26%, H: 4.39%, N: 2.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com