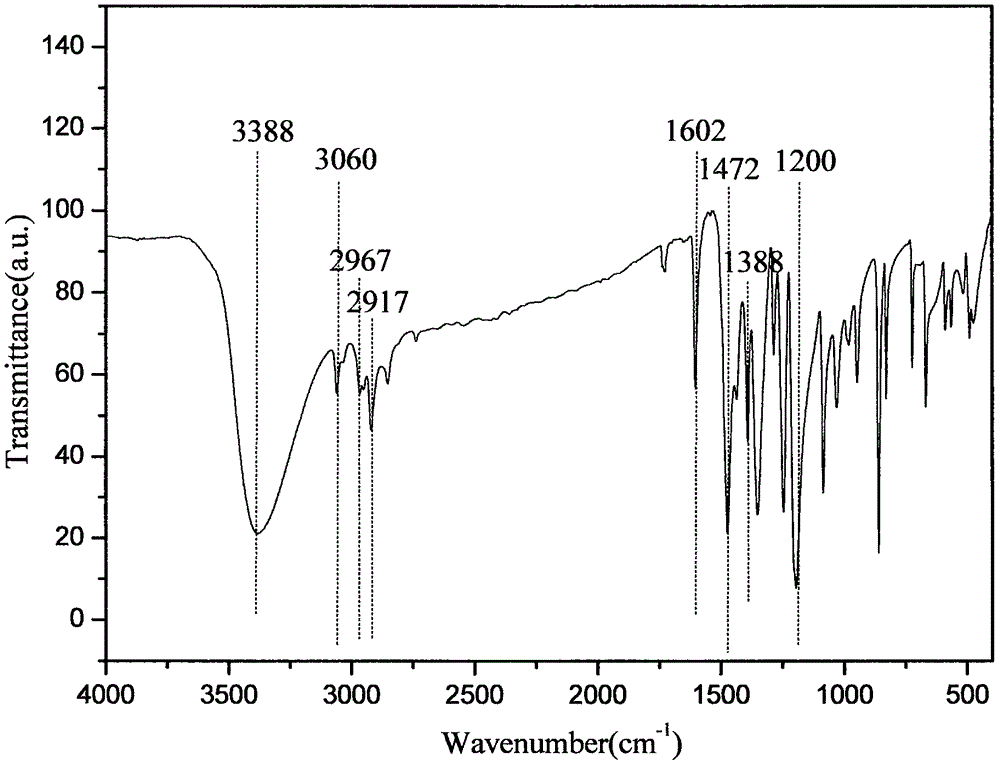

Method for synthesizing high purity 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol

A technology of biphenol and dimethylphenol, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems that have not been effectively solved and the product purity is difficult to meet the requirements and needs of the rapid development of electronic packaging materials. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

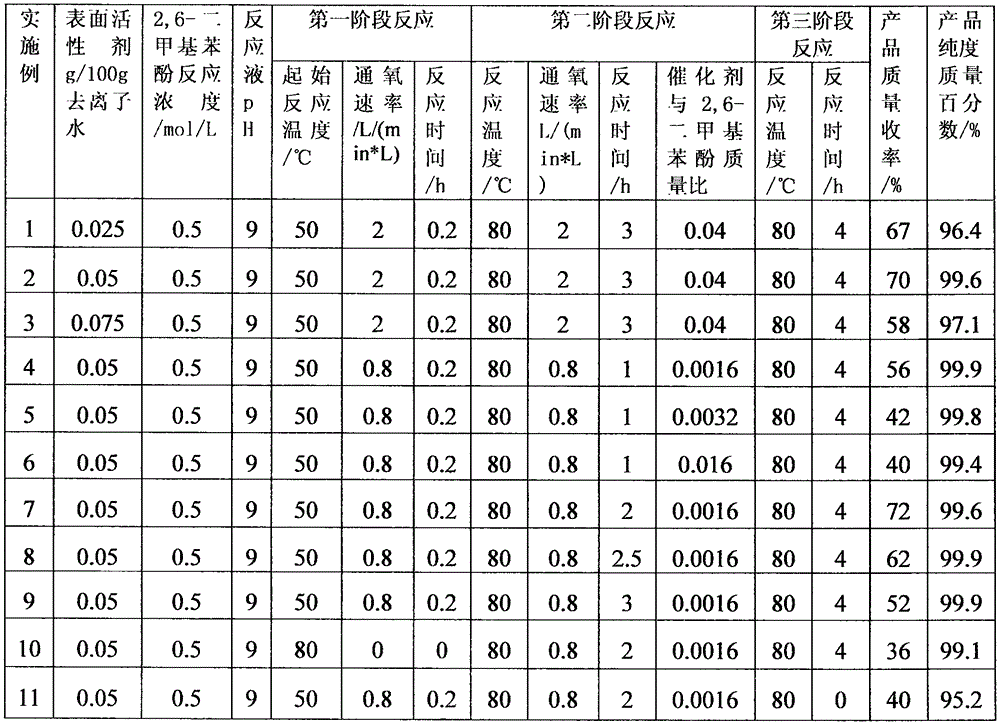

Embodiment 1

[0025] Example 1 Add 0.05g of anionic surfactant compounded with sodium dodecyl sulfonate and sodium dodecylbenzene sulfonate with a mass ratio of 1:1 and 180ml of deionized water into a thermometer and agitator. In the three-necked flask, slowly raise the temperature to 50°C under stirring to form an emulsion, then add borax to adjust the pH value of the emulsion to 9, then slowly add 12.20 g of the reaction raw material 2,6-dimethylphenol under stirring, and use 2 L / (min*L reaction liquid) gas velocity through oxygen reaction, and at the same time, slowly raise the temperature to 80°C at a heating rate of 2°C / min, then add copper acetate and copper sulfate with a concentration of 25g / L and a mass ratio of 1:1 20ml of the compound copper salt catalyst aqueous solution, continue to react with oxygen at a gas rate of 2L / (min*L reaction solution) for 3h under stirring and constant temperature of 80°C, then stop feeding oxygen, keep stirring and constant temperature of 80°C for c...

Embodiment 2

[0026] Example 2 Add 0.10 g of anionic surfactant compounded with sodium dodecyl sulfonate and sodium dodecyl benzene sulfonate with a mass ratio of 1:1 and 180 ml of deionized water into a thermometer and agitator. In the three-necked flask, slowly raise the temperature to 50°C under stirring to form an emulsion, then add borax to adjust the pH value of the emulsion to 9, then slowly add 12.20 g of the reaction raw material 2,6-dimethylphenol under stirring, and use 2 L / (min*L reaction liquid) gas velocity through oxygen reaction, and at the same time, slowly raise the temperature to 80°C at a heating rate of 2°C / min, then add copper acetate and copper sulfate with a concentration of 25g / L and a mass ratio of 1:1 20ml of the compound copper salt catalyst aqueous solution, continue to react with oxygen at a gas rate of 2L / (min*L reaction solution) for 3h under stirring and constant temperature of 80°C, then stop feeding oxygen, keep stirring and constant temperature of 80°C fo...

Embodiment 3

[0027] Example 3 Add 0.15 g of anionic surfactant compounded with sodium dodecyl sulfonate and sodium dodecyl benzene sulfonate with a mass ratio of 1:1 and 180 ml of deionized water into a thermometer and agitator. In the three-necked flask, slowly raise the temperature to 50°C under stirring to form an emulsion, then add borax to adjust the pH value of the emulsion to 9, then slowly add 12.20 g of the reaction raw material 2,6-dimethylphenol under stirring, and use 2 L / (min*L reaction liquid) gas velocity through oxygen reaction, and at the same time, slowly raise the temperature to 80°C at a heating rate of 2°C / min, then add copper acetate and copper sulfate with a concentration of 25g / L and a mass ratio of 1:1 20ml of the compound copper salt catalyst aqueous solution, continue to react with oxygen at a gas rate of 2L / (min*L reaction solution) for 3h under stirring and constant temperature of 80°C, then stop feeding oxygen, keep stirring and constant temperature of 80°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com