A method for removing scale and heavy metal ions in water

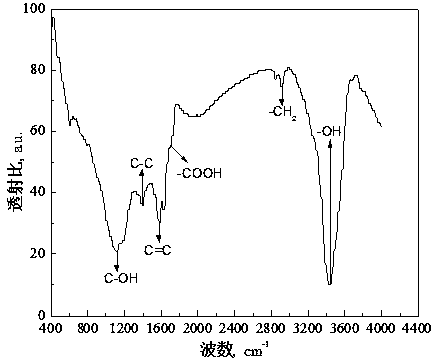

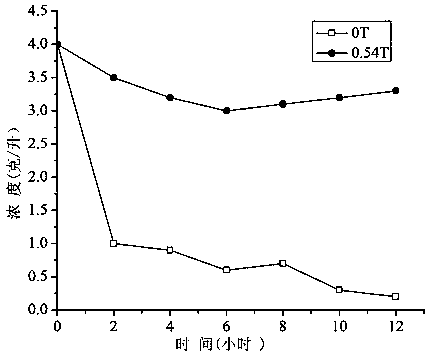

A heavy metal ion and water removal technology, applied in the field of water treatment, can solve the problems of weak adsorption capacity of graphene/carbon nanotube composite materials, agglomeration of graphene and carbon nanotubes, and low orderly arrangement of carbon nanotubes, etc. The effect of mild conditions, good adsorption capacity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

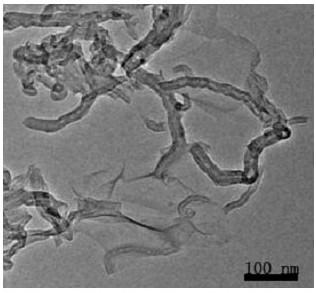

[0034] Step 1 Pretreatment of carbon nanotubes:

[0035] Disperse 1g of original multi-walled carbon nanotubes (prepared by chemical vapor deposition) into a mixed acid solution consisting of 30ml of concentrated sulfuric acid and 10ml of concentrated nitric acid, stir and react at 60°C for 3 hours, wash with distilled water until neutral, and dry in vacuum at 80°C Reserve after 12 hours.

[0036] The preparation of step 2 graphene oxide:

[0037] Take 2g of natural flake graphite with an electronic balance, use a graduated cylinder to measure 46ml of concentrated sulfuric acid and pour it into a 1000ml three-neck bottle, cool to 0~5°C, add the weighed 2g of graphite to 46ml of concentrated sulfuric acid, Use an ice bath to cool to 0~5°C and stir until the graphite is completely dissolved, add 1g of sodium nitrate and 6g of potassium permanganate at a certain speed while stirring vigorously, keep the temperature of the mixture below 10°C and continue stirring for 2.5 hours; r...

Embodiment 2

[0044] Step 1 Pretreatment of carbon nanotubes:

[0045] Disperse 2 g of original multi-walled carbon nanotubes (prepared by chemical vapor deposition) into a mixed acid solution of 60 ml of concentrated sulfuric acid and 20 ml of concentrated nitric acid, stir and react at 60°C for 3 hours, wash with distilled water until neutral, and dry in vacuum at 80°C for 12 Stand by after hours.

[0046] The preparation of step 2 graphene oxide:

[0047] Take 4g of natural flake graphite with an electronic balance, use a measuring cylinder to measure 92ml of concentrated sulfuric acid and pour it into a 1000ml three-neck bottle, cool to 0~5°C, add the weighed 4g of natural graphite into 92ml of concentrated sulfuric acid , use an ice bath to cool to 0~5°C and stir until the graphite is completely dissolved, add 2g of sodium nitrate and 12g of potassium permanganate at a certain speed while stirring vigorously, keep the temperature of the mixture below 10°C and continue stirring for 2.5...

Embodiment 3

[0054] Step 1 Pretreatment of carbon nanotubes:

[0055] Disperse 0.5g of original multi-walled carbon nanotubes (prepared by chemical vapor deposition) into a mixed acid solution of 15ml of concentrated sulfuric acid and 5ml of concentrated nitric acid, stir and react at 60°C for 3 hours, wash with distilled water until neutral, and dry in vacuum at 80°C Reserve after 12 hours.

[0056] The preparation of step 2 graphene oxide:

[0057] Use an electronic balance to take 2g of natural flake graphite, use a graduated cylinder to measure 46ml of concentrated sulfuric acid and pour it into a 1000ml three-neck bottle, cool to 0~5°C, add the weighed 2g of natural graphite to 92ml of concentrated sulfuric acid , use an ice bath to cool to 0~5°C and stir until the graphite is completely dissolved, add 2g of sodium nitrate and 12g of potassium permanganate at a certain speed while stirring vigorously, keep the temperature of the mixture below 10°C and continue stirring for 2.5 hours;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com