Coal ash gas delivery system

A conveying system and fly ash technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of easy silting of materials, silo pump conveying cannot fully meet industrial production, and silo pump is easy to block, etc. The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

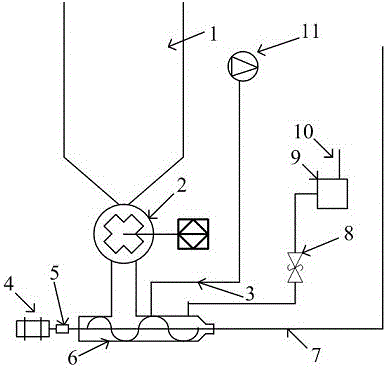

[0013] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0014] A fly ash gas conveying system, comprising an ash hopper 1, a star unloader 2, a feeding screw device 6 and a control system, the star unloader 2 is installed at the bottom of the ash hopper 1 to control the flow of materials The conveying capacity enables the material to fall continuously and evenly. A feeding screw device 6 is installed at the bottom of the star unloader 2; a compressed air inlet pipe 3 is installed in the middle of the feeding screw device 6, and a pressure relief pipe is installed in the middle and rear. 10. The pressure relief pipeline 10 is equipped with a pressure relief valve 8 and a dust collection device 9 for pressure relief treatment in special cases. In order to prevent the materials in the pipeline from being discharged through the pressure relief valve, causing envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com