Lightweight traction rod for urban rail vehicle

A technology of urban rail vehicles and traction rods, which is applied in the direction of traction devices, railway car body parts, transportation and packaging, etc. It can solve problems such as difficulty in achieving weight reduction goals, complex molding processes, and single product structure, and achieve reduction in vehicle operating capacity. The effect of reducing consumption, optimizing rod section, and reducing load weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

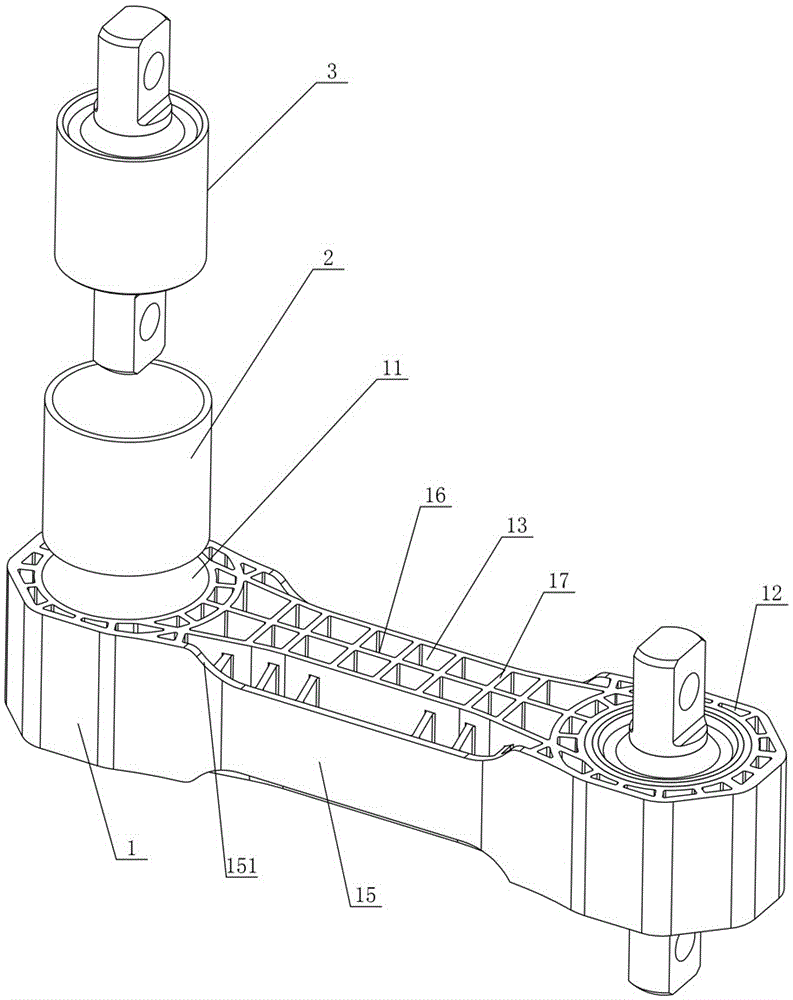

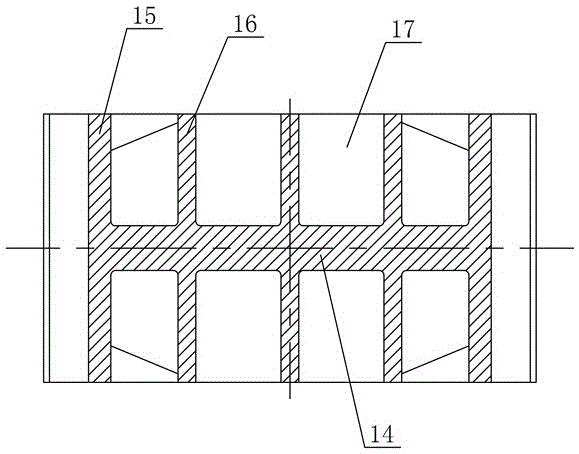

[0030] Figure 1 to Figure 4 The first embodiment of the lightweight traction rod for urban rail vehicles of the present invention is shown, including a rod body 1, two metal mounting rings 2 and two elastic nodes 3. The rod body 1 is formed of fiber-reinforced plastic, and the two elastic nodes are 3. It is made of high-strength steel. The two ends of the rod body 1 are provided with mounting holes 11. The two metal mounting rings 2 are integrally formed with the two mounting holes 11, respectively. The two elastic nodes 3 are respectively connected with the two metal mounting circles. The ring 2 has an interference fit. The rod body 1 is provided with a plurality of first hollow parts 12 along the periphery of the installation hole 11 that are consistent with the axis direction of the installation hole 11. The second hollow portion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com