High-shrinkage three-dimensional wrinkled texture embossed knitted thermal composite fabric and preparation method thereof

A composite fabric and high-shrinkage technology, which is applied in the field of knitted fabrics, can solve the problems of inability to effectively guarantee the color depth of the fabric, the reduction of wrinkle resistance and wear resistance, and the thin texture of the fabric, and achieve good application prospects, good elasticity, and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail and concretely below through specific examples to better understand the present invention, but the following examples do not limit the scope of the present invention.

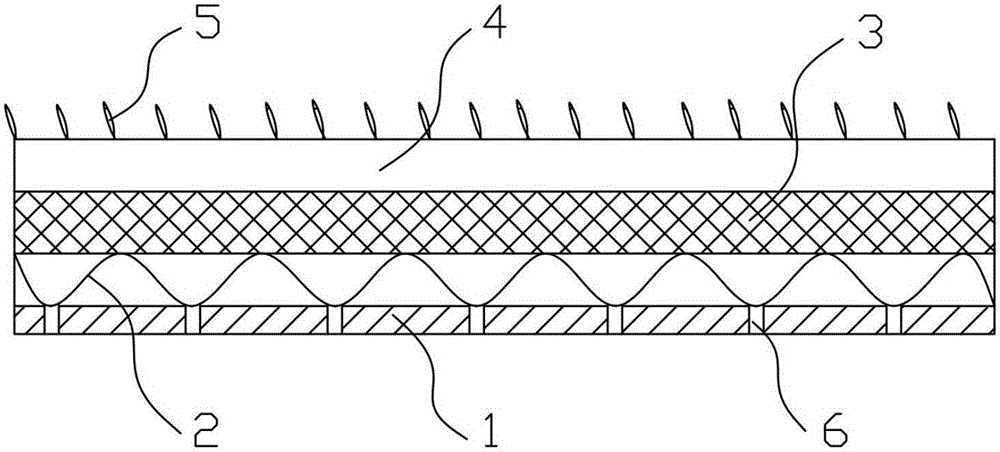

[0027] Such as figure 1 As shown, this embodiment provides a high shrinkage three-dimensional wrinkle texture relief warm knitted composite fabric. The composite fabric includes an inner layer 1, a cushion layer 2, a fabric layer 3, which are connected together by connecting wires from the inside to the outside. The outer layer 4 is then made after post-treatment; among them, the inner layer 1 is composed of moisture-absorbing yarn and cotton yarn fibers, which are knitted by one strand of moisture-absorbing yarn and two blended cotton yarn fibers; the backing layer 2 is made of high shrinkage poly Acrylonitrile fiber, high-shrinkage polypropylene fiber and cotton yarn are woven to form a V-shaped structure blended yarn; the fabric layer 3 is a weft knitted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com