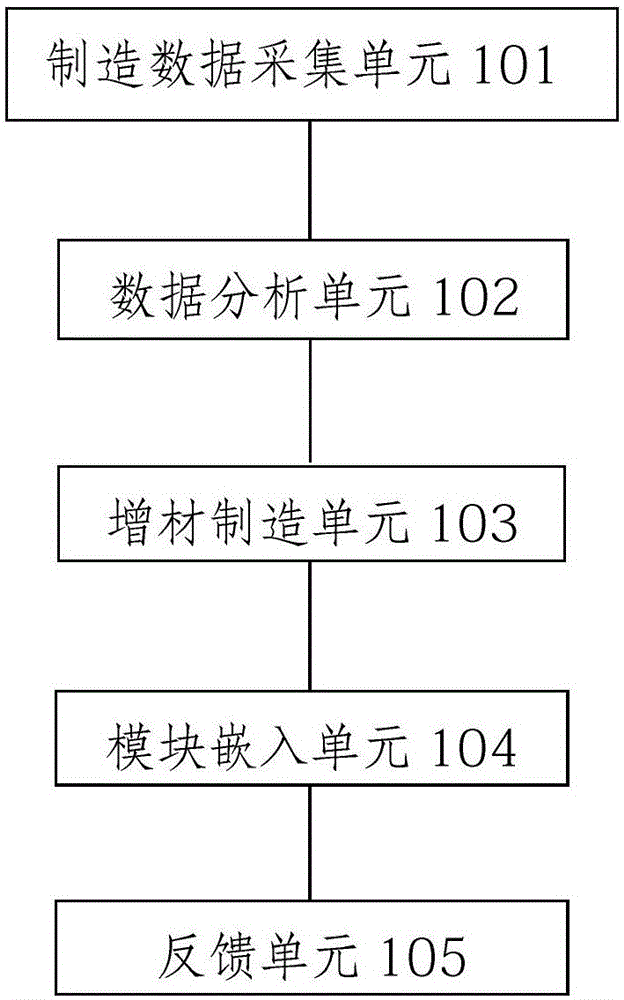

Additive manufacturing method and device

A technology of additive manufacturing and objects, applied in the field of additive manufacturing, can solve problems such as low efficiency, long time, and low mechanical strength of products, so as to achieve the effect of reducing costs, avoiding waste, and maximizing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

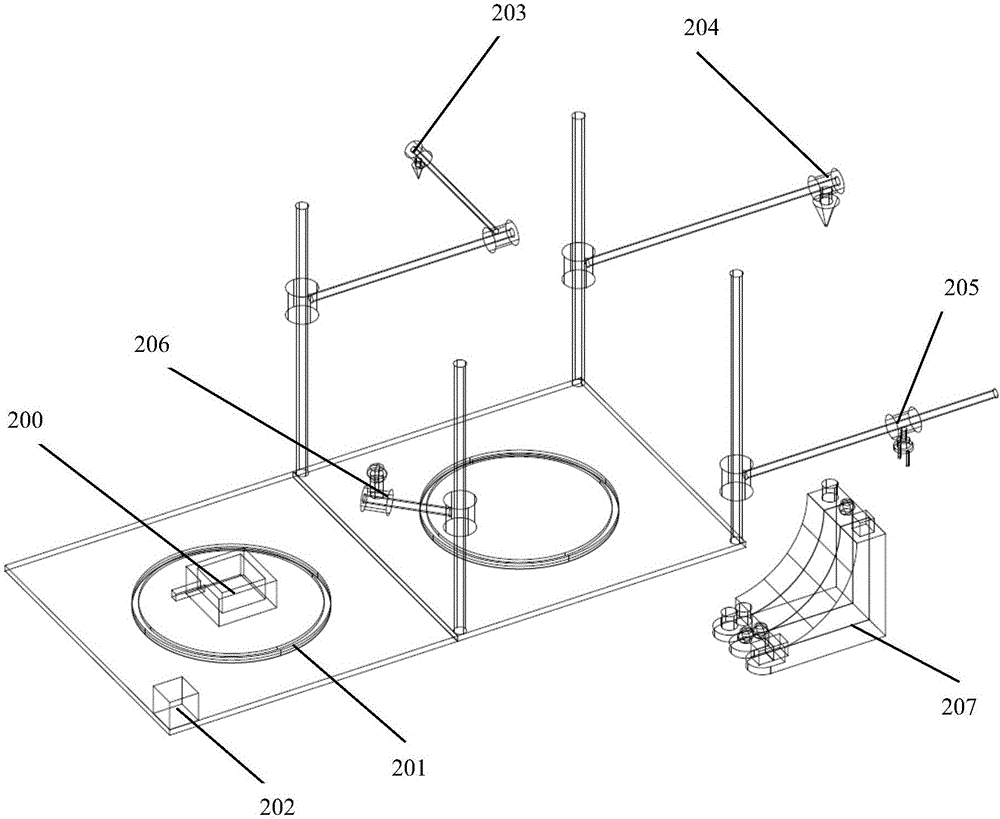

[0087] The fused deposition printing of the present invention is taken as an example for illustration.

[0088] Such as figure 2 A schematic diagram showing the device of the present invention performing fused deposition printing. The printing device at least includes a turntable 201 , a data analysis control module 202 , a first manipulator 203 , a second manipulator 204 , a module embedding manipulator 205 , a three-dimensional data scanning monitoring module 206 and a module warehouse 207 . The turntable 201 is used to drive the target object 200 to rotate when the three-dimensional data scanning monitoring module 206 scans the target object 200 .

[0089] The manufacturing data acquisition unit 101 includes a three-dimensional data scanning monitoring module 206 , and the data analysis unit 102 includes a data analysis control module 202 . The additive manufacturing unit 103 includes a first manipulator 203 and a second manipulator 204 . The first manipulator 203 has at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com