Water jet saw with front and rear double-stroke feeding function

A cutting machine and double-stroke technology, applied in the field of CNC machine tools, can solve the problems of increased accidental risk, difficult operation, and low production efficiency, and achieve the effect of reducing accidental handling of brittle materials, reducing operational difficulty, and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

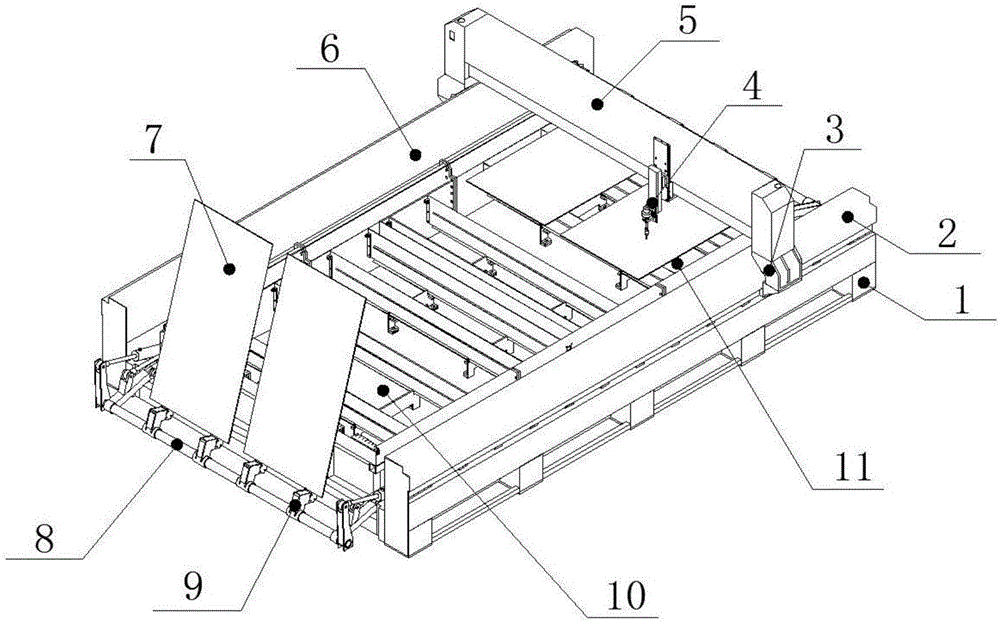

[0022] Such as figure 1 , figure 2 , image 3 As shown, a waterjet cutting machine capable of feeding front and rear double strokes includes a frame 1 and left Y beam 6 and right Y beam 2 respectively arranged on the left and right sides of frame 1, left Y beam 6 and right Y beam. An X beam 5 is movable on the beam 2, and the X beam 5 is movably connected with the left Y beam 2 and the right Y beam 6 through the aluminum base 3. The cutter head 4 is movable on the X beam 5, and the inside of the frame 1 There is a water tank 18, the front and rear sides of the water tank 18 are respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com