Hub centering and clamping device

A technology of clamping device and wheel hub, which is applied in the field of automobile manufacturing, can solve the problems of high cost and complex structure, and achieve the effect of low cost, accurate position and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

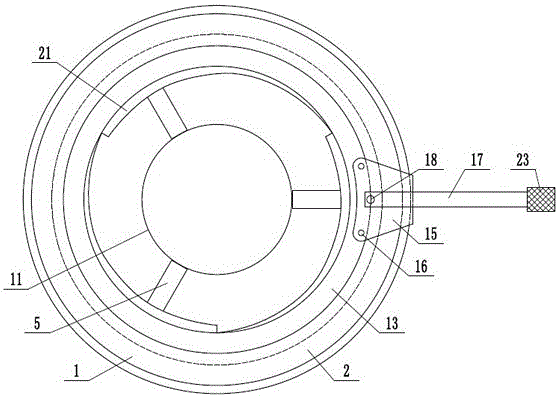

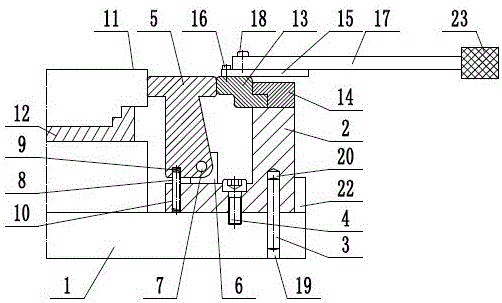

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0013] like figure 1 and figure 2 As shown, a centering clamping device for a wheel hub includes a support base 1, a support ring 2, a positioning pin shaft 3, a fastening screw 4, a claw 5, a claw support seat 6, a claw pin shaft 7, a compression Spring 8, upper spring groove 9, lower spring groove 10, hub 11, hub support seat 12, drive turntable 13, pressure ring 14, connecting plate 15, first screw 16, control handle 17, second screw 18, described hub The support seat 12 is fixed at the center of the support base 1, the hub 11 is installed on the hub support seat 12, the support base 1 is provided with two or more lower pin holes 19, and the support ring 2 is provided with There is a corresponding upper pin ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com