An ultra-fast femtosecond laser cutting machine

A femtosecond laser, femtosecond laser technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of high equipment capability requirements, low practical cutting efficiency, and reduced single pulse superposition, and achieve material quality. No damage, high yield and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments.

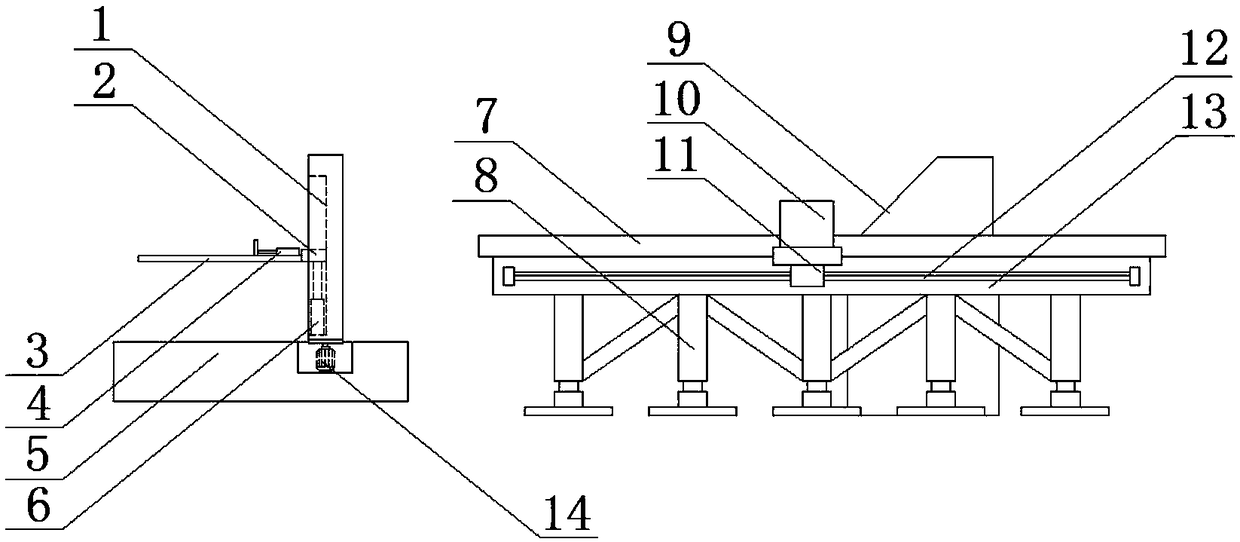

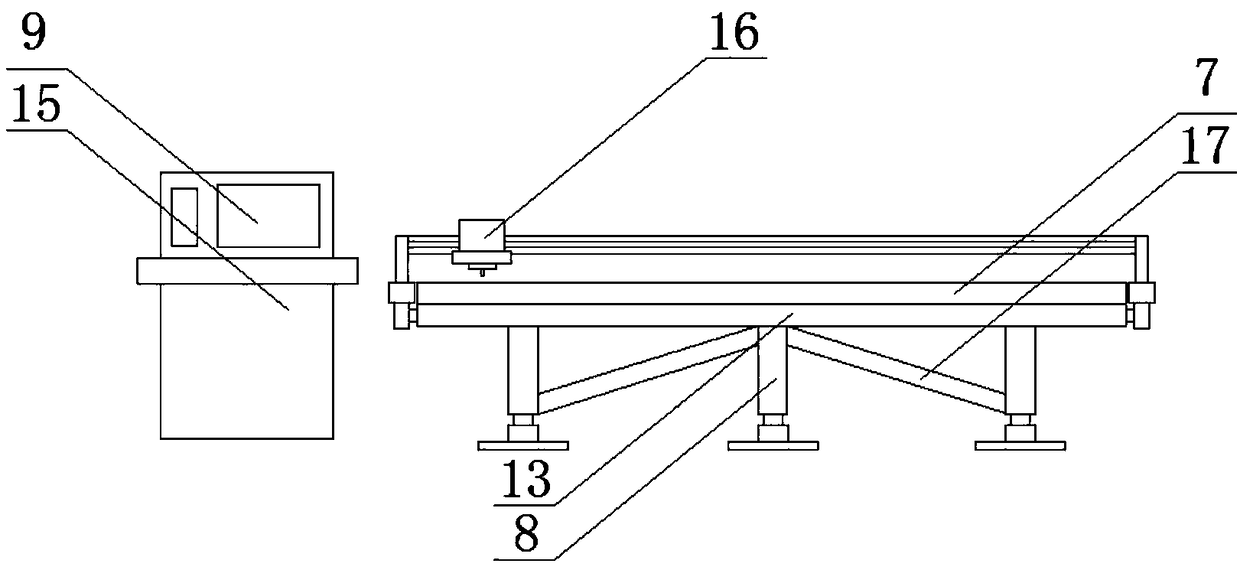

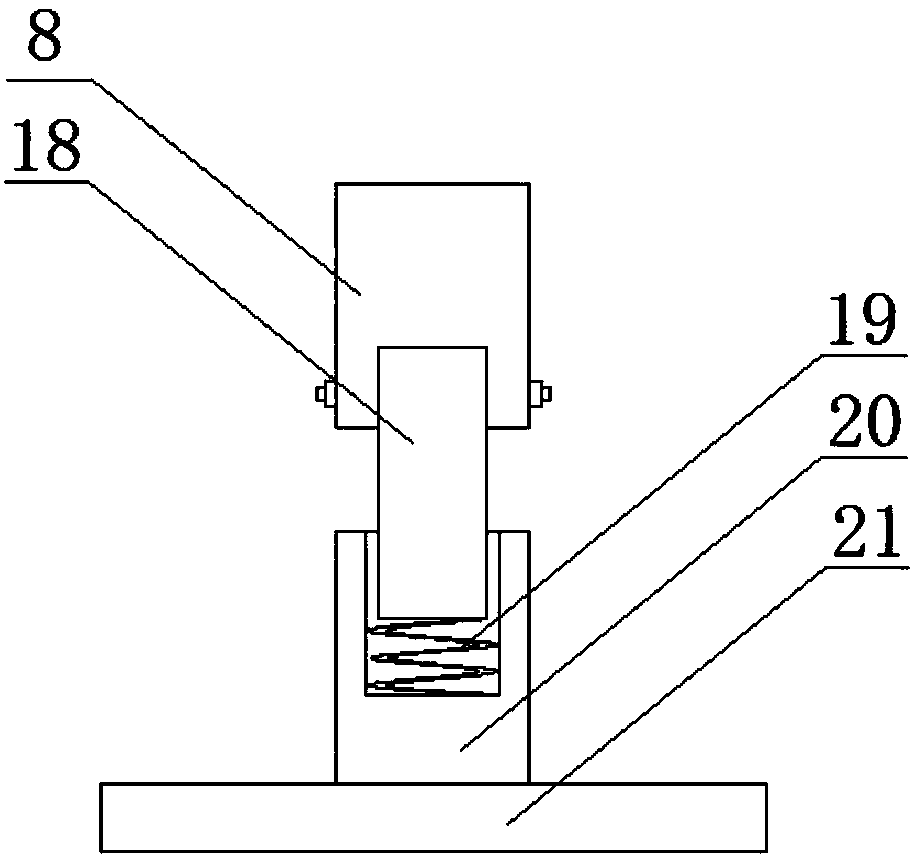

[0024] refer to Figure 1-4 , a kind of ultra-fast femtosecond laser cutting machine, comprises bearing platform 13, and the lower end of bearing platform 13 is equidistantly provided with a plurality of support rods 8, plays a supporting role, and the lower end of support rods 8 is provided with damping device, and two Connecting rods 17 are all provided between adjacent support rods 8, and the upper end of bearing platform 13 is provided with bearing plate 7, and the both sides of bearing platform 13 are all provided with first electric slide rail 12, and the first electric slide rail 12 is installed There is a second slider 11, the second slider 11 can move on the first electric slide rail 12, the upper end of the second slider 11 is provided with a mounting block, the upper end of the mounting block is fixed with a first vertical plate 10, two second A mounting plate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com