Sand box with pressing device

A technology of pressing device and sand box, which is applied in the field of foundry tooling, can solve problems such as difficult alignment of upper and lower sand boxes, scrapped castings, and long service life, so as to prevent deformation of the sand box and protect quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

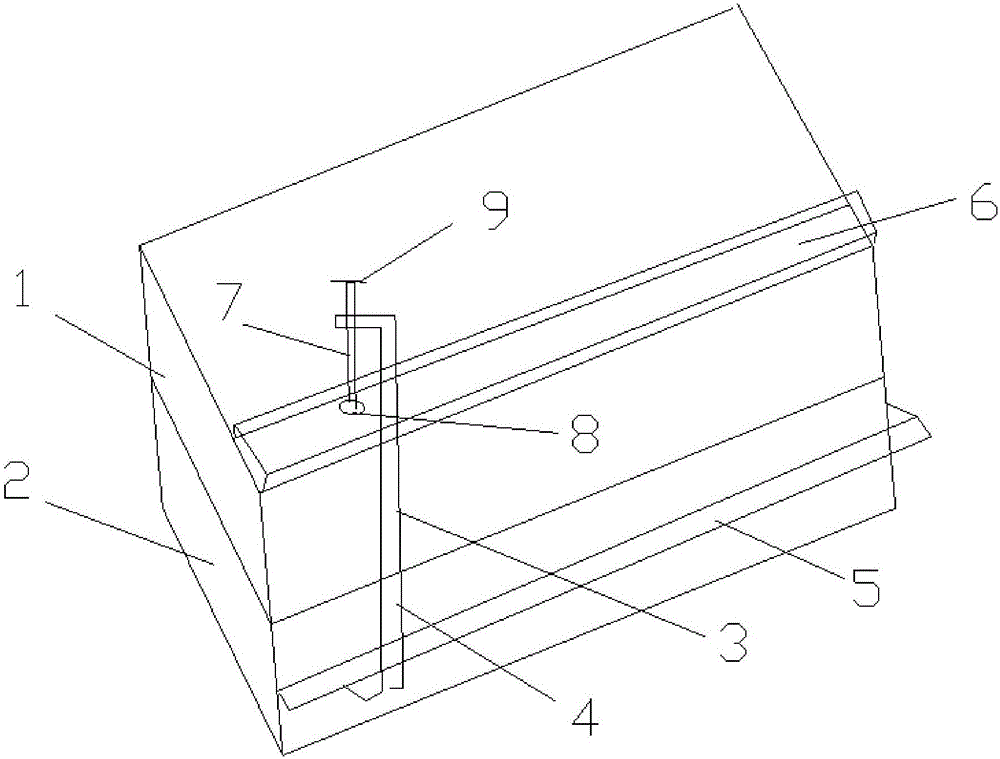

[0018] Such as figure 1 A sand box with a pressing device provided in this embodiment includes an upper sand box 1, a lower sand box 2, a pressing device 3, a bow-shaped connecting rod 4, a connecting plate 5, a pressing iron plate 6, and a rotating screw 7 , pressing block 8 and rotating handle 9; Upper sand box and lower sand box are fixed by pressing device 3, and wherein, pressing device comprises arcuate connecting rod 4, connecting plate 5 and rotating screw rod 7, and connecting plate 5 is fixed on the lower sand box Case 2 one side, bow-shaped connecting rod 4 lower ends are fixed on the connecting plate 5, and the upper end is positioned at upper sand box 1 top, and rotating screw rod 7 is rotatably connected on the bow-shaped connecting rod 4 upper ends.

[0019] In this embodiment, the upper end of the bow-shaped connecting rod is provided with a vertical through hole, and an internal thread is provided in the through hole, and an external thread adapted to the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com