Construction waste treatment device with dual functions of crushing and screening

A construction waste and treatment device technology, applied in grain treatment, sieves, chemical instruments and methods, etc., can solve the problems of unreasonable structural design, incomplete pulverization, poor work efficiency, etc., and achieve good pulverization effect and low production cost. , good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

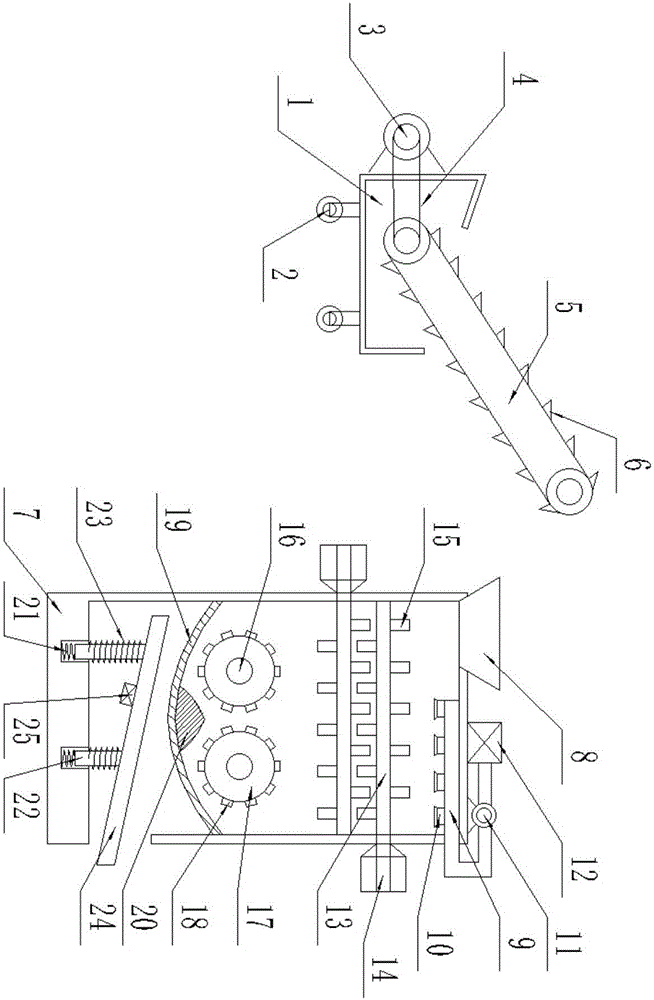

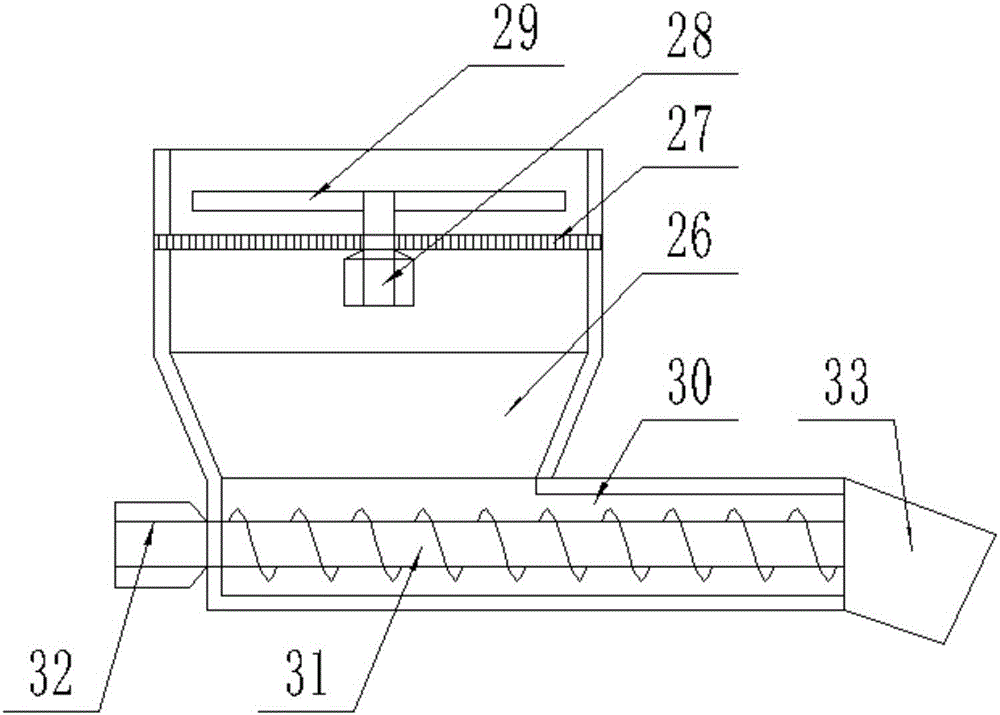

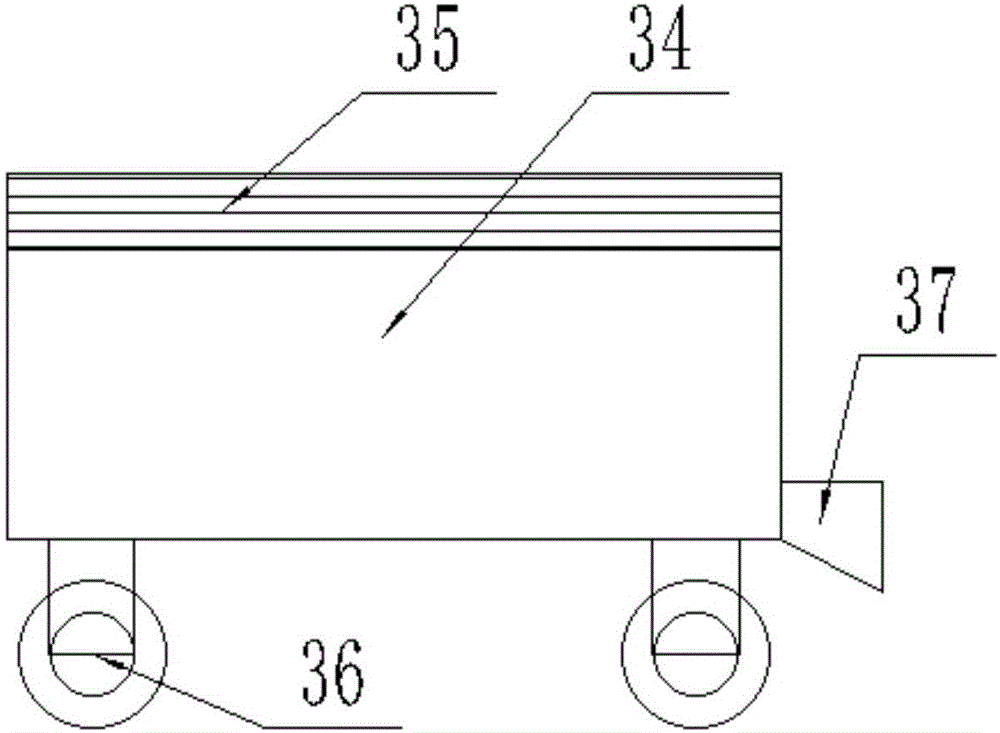

[0023] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a construction waste treatment device with dual functions of crushing and screening, including: lifting box 1, pulley 2, lifting motor 3, belt 4, timing belt 5 and material net 6, The lower surface of the lifting box 1 is provided with several pulleys 2, and the outer surface of the lifting box 1 is fixedly connected with a lifting motor 3, and one end of the synchronous belt 5 is arranged in the lifting box 1, and the synchronous belt 5 Several material nets 6 are fixedly connected to the outer surface of the machine, which also includes a crushing chamber 7, an inlet 8, an air duct 9, an air nozzle 10, a suction fan 11, a dust chamber 12, a crushing shaft 13, a crushing motor 14, a crushing blade 15, a mill Finale 16, rolling plate 17, rolling teeth 18, first filter screen 19, partition block 20, first spring 21, pin 22, second spring 23, swash plate 24 and vibration motor 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com