Double-cycle desulphurization and dust removal device and flue gas desulphurization and dedusting method

A desulfurization and dust removal, double-circulation technology, which is applied in combination devices, separation devices, separation methods, etc., can solve the problems of failing to meet environmental protection standards, large footprint, poor flue gas treatment effect, etc. Turbulence, the effect of reducing overall volume and footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

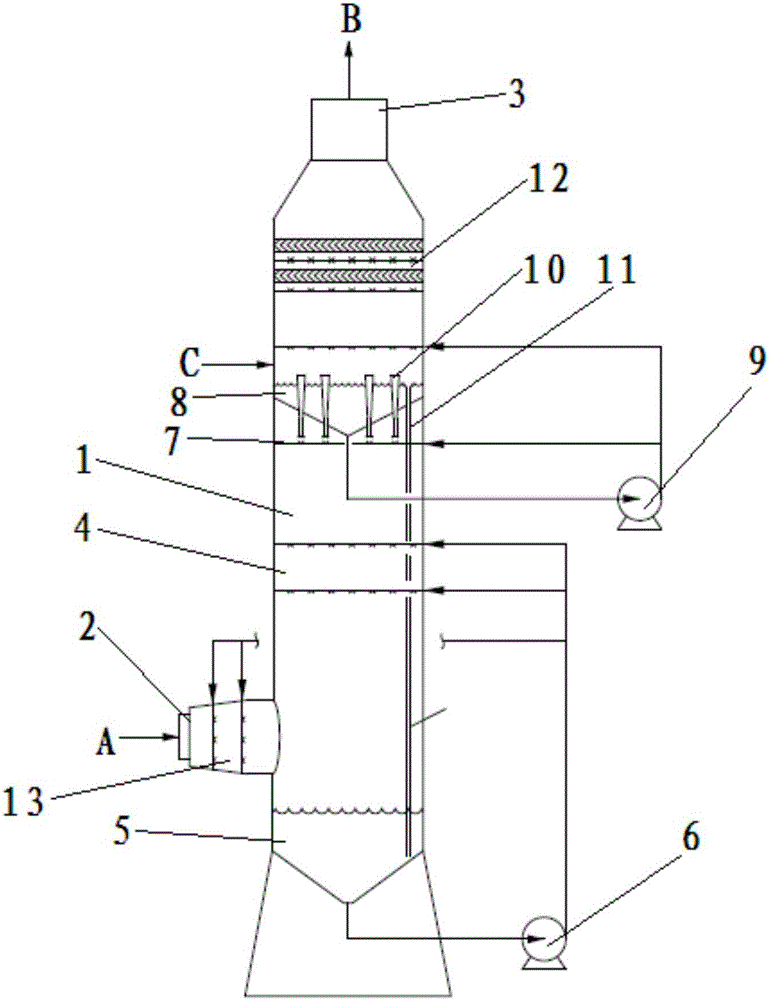

[0029] like figure 1 As shown, Embodiment 1 discloses a dual-cycle high-efficiency desulfurization and dust removal device, including: a tower body 1, including a flue gas inlet 2 arranged at the lower left of the tower body 1 and a flue gas outlet 3 arranged at the top of the tower body 1 The first-level spray layer 4 is arranged in the tower body 1 and above the flue gas inlet 2. In this embodiment, the first-level spray layer 4 includes two layers and one-level sub-spray layer; the first-level liquid storage bucket 5 , arranged in the tower body 1 and located below the primary spray layer 4, for collecting the primary spray circulating liquid; the quenching spray layer 13, arranged in the tower body 1 and close to the flue gas inlet 2, for cooling The flue gas entering from the flue gas inlet 2; the primary spray pump 6, its liquid inlet extends into the primary liquid storage bucket 5, and its liquid outlet is divided into two parts, one part is connected with the primary ...

Embodiment 2

[0034] Embodiment 2 discloses another specific embodiment of a double-cycle high-efficiency desulfurization and dust removal device. The double-cycle desulfurization and dust removal device and process conditions used in embodiment 2 and embodiment 1 are basically the same. The difference is that in this embodiment , the lye supplemented by the replenishment port of the first-level liquid storage bucket and the second-level liquid storage bucket is an aqueous lime solution, and the first-level spray layer is equipped with 5 layers of the first-level sub-spray layer, and the second-level circulation is equipped with 6 groups of Venturi tubes .

[0035] In this embodiment, lime aqueous solution is used as the first-level spray circulating fluid and the second-level spray circulating fluid to treat the flue gas. The desulfurization efficiency of this invention is 99.6%, the dust removal efficiency is 94.3%, and the sulfur content can be as high as 2%. The flue gas is treated to m...

Embodiment 3

[0037] Embodiment 3 discloses another specific embodiment of the dual-cycle high-efficiency desulfurization and dust removal device. The dual-cycle desulfurization and dust removal device and process conditions used in Embodiment 3 and Embodiment 1 are basically the same, except that the first-stage liquid storage bucket and The lye supplemented by the replenishment port of the secondary liquid storage bucket is ammonia solution, and the primary spray layer is equipped with 6 layers of primary sub-spray layers, and the secondary circulation is equipped with 8 sets of Venturi tubes.

[0038] In this embodiment, ammonia solution is used as the first-level spray circulation fluid and the second-level spray circulation fluid to treat the flue gas. The desulfurization efficiency of this invention is 99.7%, the dust removal efficiency is 94.5%, and the sulfur content can be as high as 2%. The flue gas is treated to meet the "ultra-clean emission" standard.

[0039] Combining Embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com