Corona wet desulfurization and denitrification dust removal flue gas purification device and using method thereof

A technology for wet desulfurization, denitrification and dust removal, which is applied in the direction of chemical instruments and methods, combined devices, separation methods, etc. It can solve the problems of not being able to meet the design requirements for removing large-flow gas and dust, and being difficult to meet environmental protection standards for smoke exhaust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

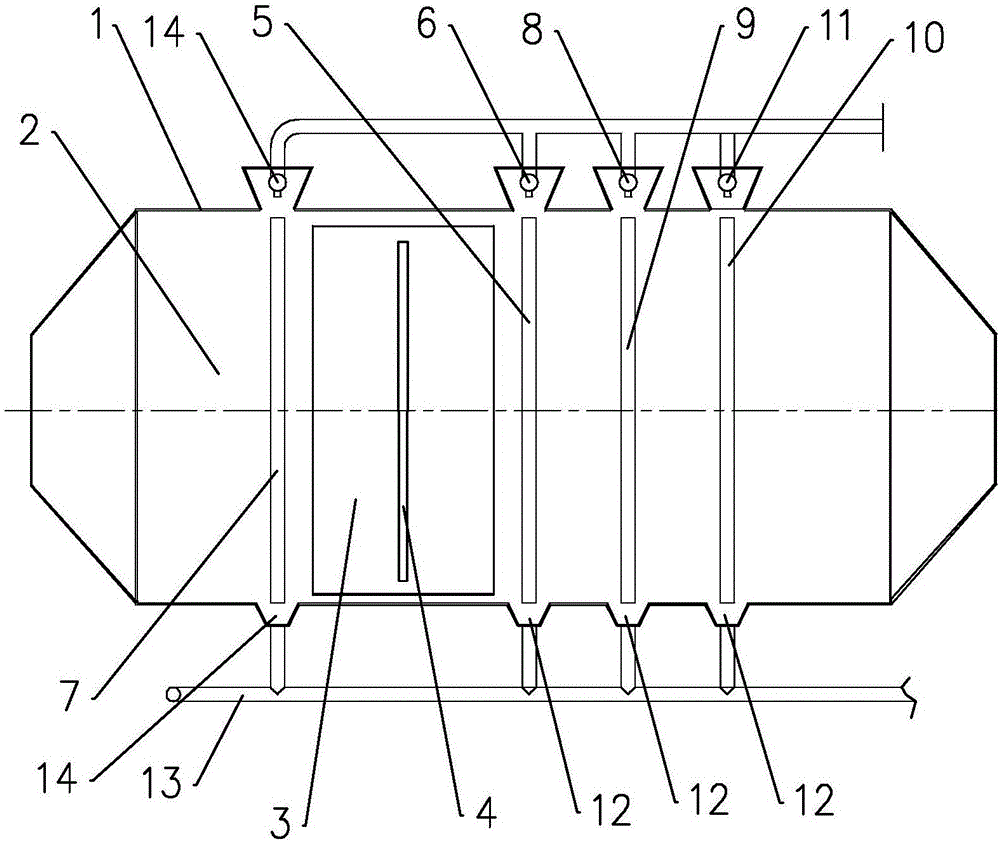

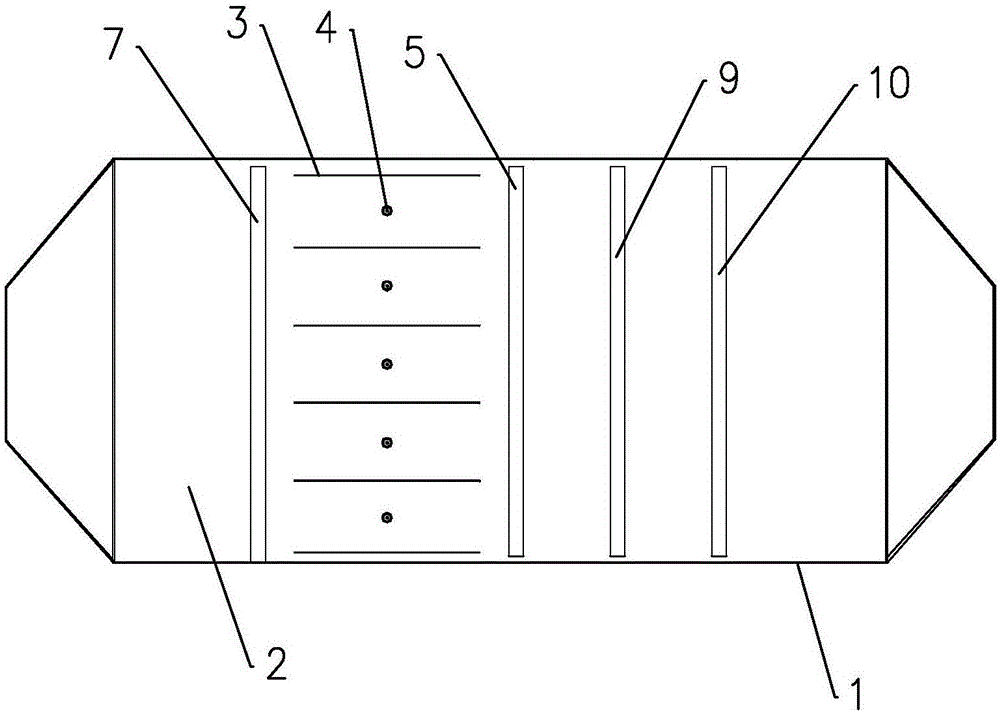

[0022] like figure 1 , figure 2 As shown, the corona wet desulfurization, denitrification and dust removal flue gas purification device of the present invention includes a casing 1, and the flue gas purification air passage 2 is arranged in the casing 1 along the front and rear directions, and the front part of the casing 1 is provided with a flue gas purification The air inlet of the air passage 2, the exhaust port of the flue gas purification air passage 2 is provided at the rear of the casing 1, and a plurality of anode plates 3 are arranged side by side in the flue gas purification air passage 2, and the plates of the plurality of anode plates 3 The surface is located in the front and back vertical direction, and the board surfaces of a plurality of anode plates 3 are parallel to each other, and the top of each anode plate 3 is respectively provided with an anode spray pipe (not shown in the figure) along the front and rear direction, and each anode spray pipe The water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com