Combined type radial current electric dust collector

An electrostatic precipitator and combined technology, which is applied in the field of combined radial flow electrostatic precipitators, can solve the problems that it is difficult to meet the treatment requirements, the power generation boiler is difficult to meet the environmental protection standards for smoke exhaust, and the PM2.5 cannot be removed efficiently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

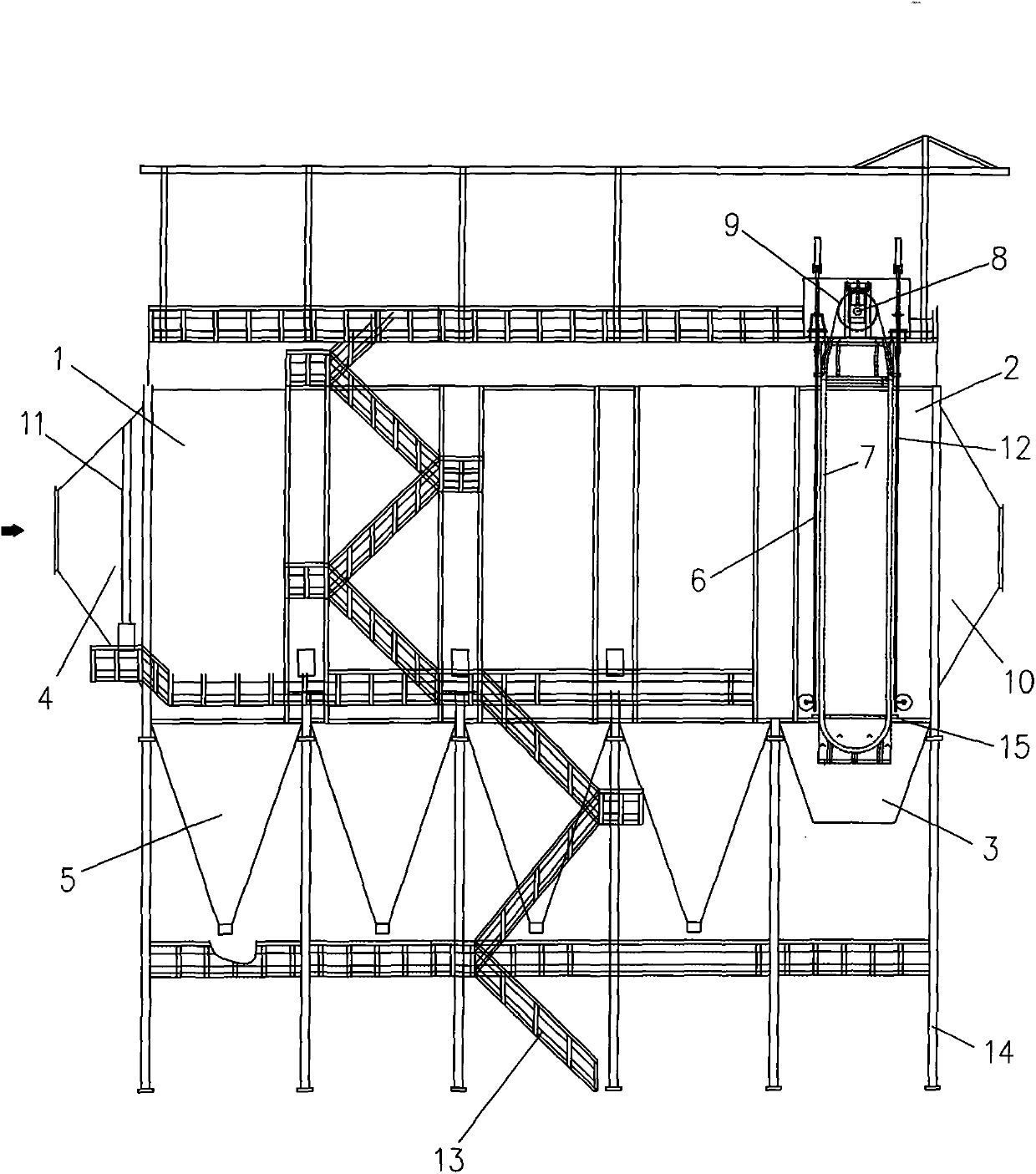

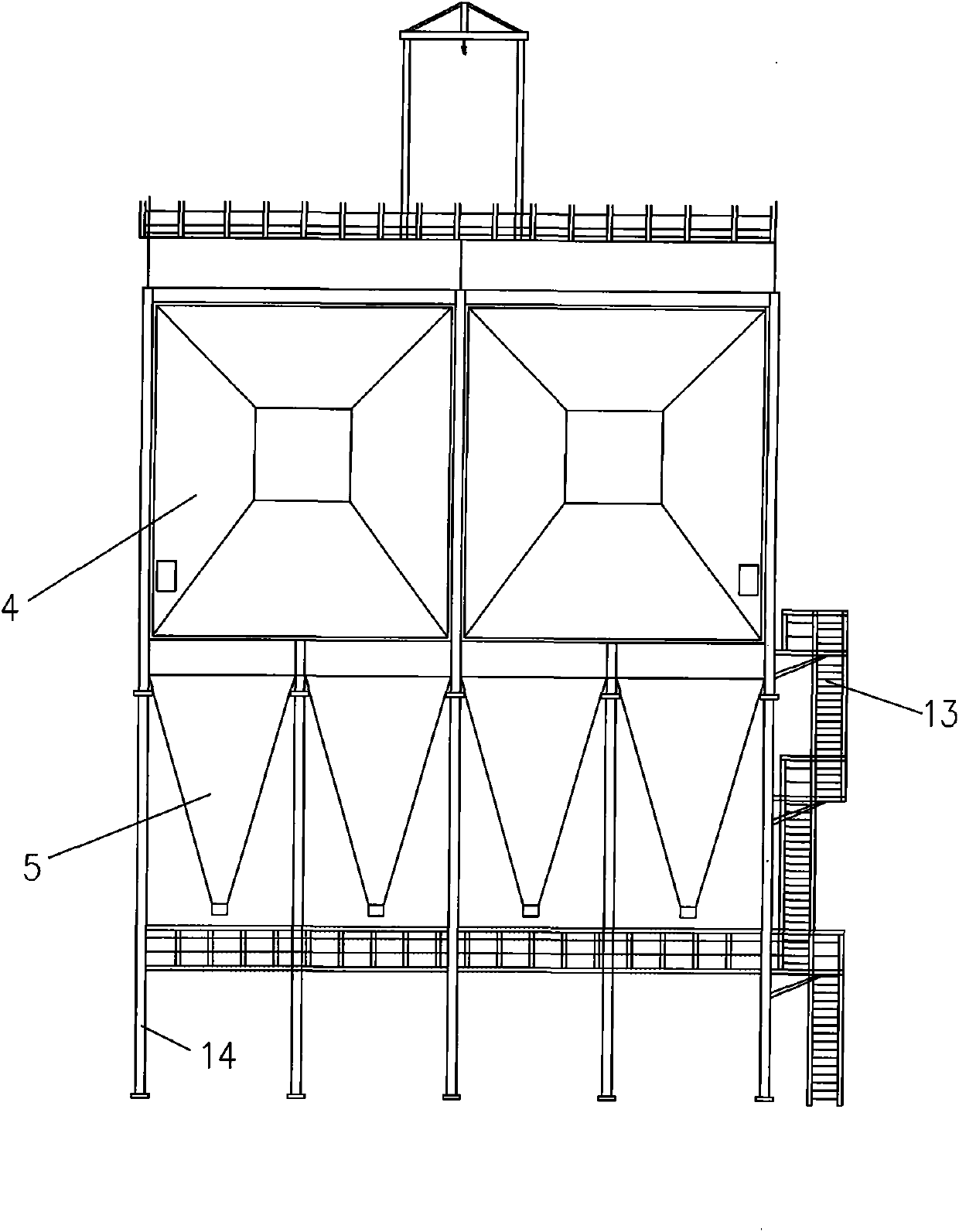

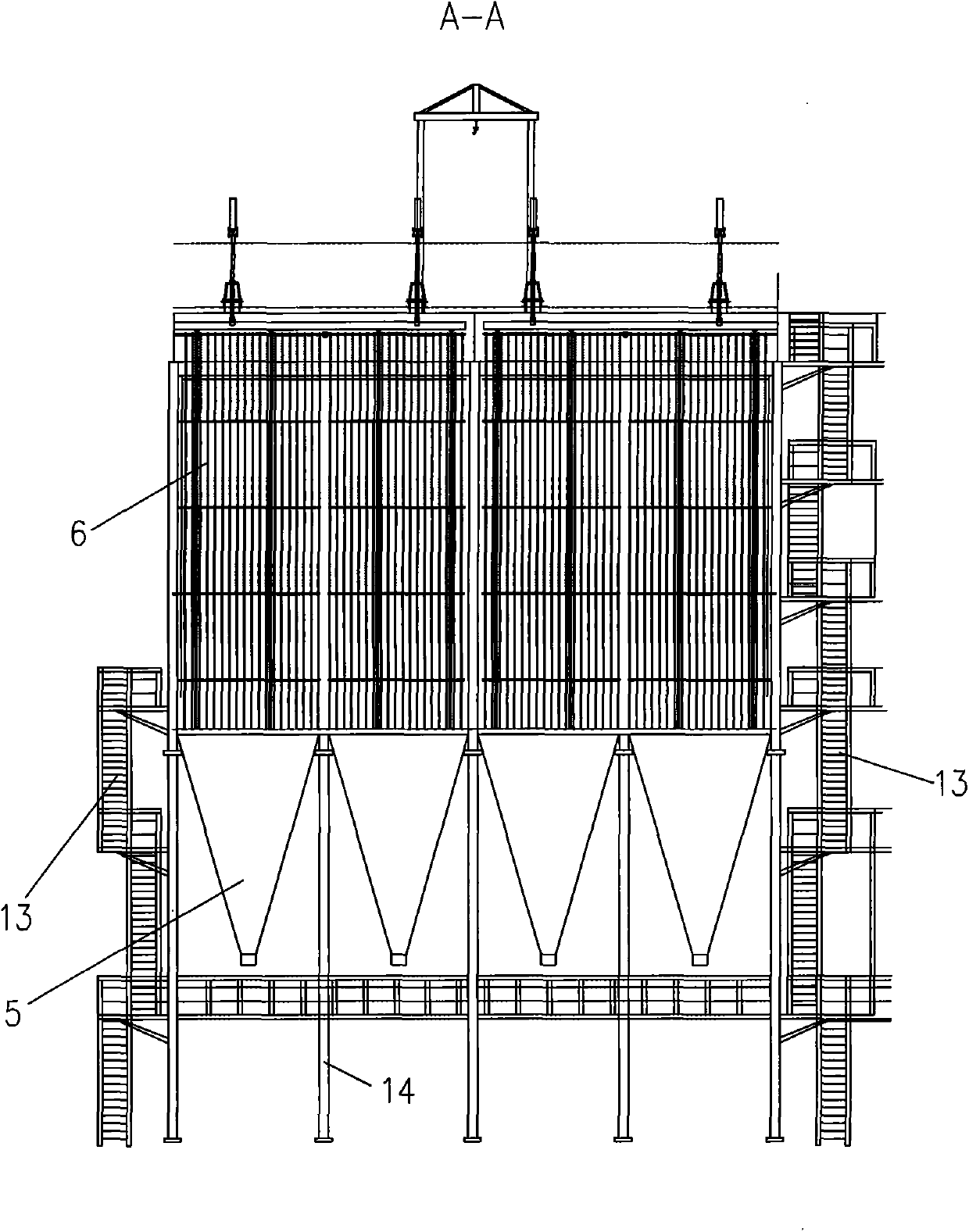

[0025] Such as figure 1 , figure 2 with image 3 As shown, the combined radial flow electrostatic precipitator of the present invention includes a housing 1. The housing 1 is provided with a dust removal air passage 2 along the front and rear directions, and the front of the housing 1 is provided with an air inlet for the dust removal air passage 2. The rear of the shell 1 is provided with an exhaust port for the dust removal air duct 2. The dust removal air duct 2 is equipped with a discharge electrode (not shown in the figure) that can charge the dust particles in the air and a collector for adsorbing dust particles. Dust electrode (not shown in the figure), below the dust collecting electrode is equipped with a ash hopper 5 for collecting dust falling from the dust collecting electrode, and the dust removal air duct 2 is located behind the dust collecting electrode with a radial electric dust removal discharge Net 6, the net surface of the radial electric precipitating and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com