A kind of arsenic sulfide slag hydrothermally stable solidification treatment method

A solidification treatment and arsenic sulfide technology, which is applied in the field of environmental protection, can solve the problems of no arsenic sulfide slag artificially synthesized minerals, etc., and achieve the effect of wide range of pretreatment agents, small dosage, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

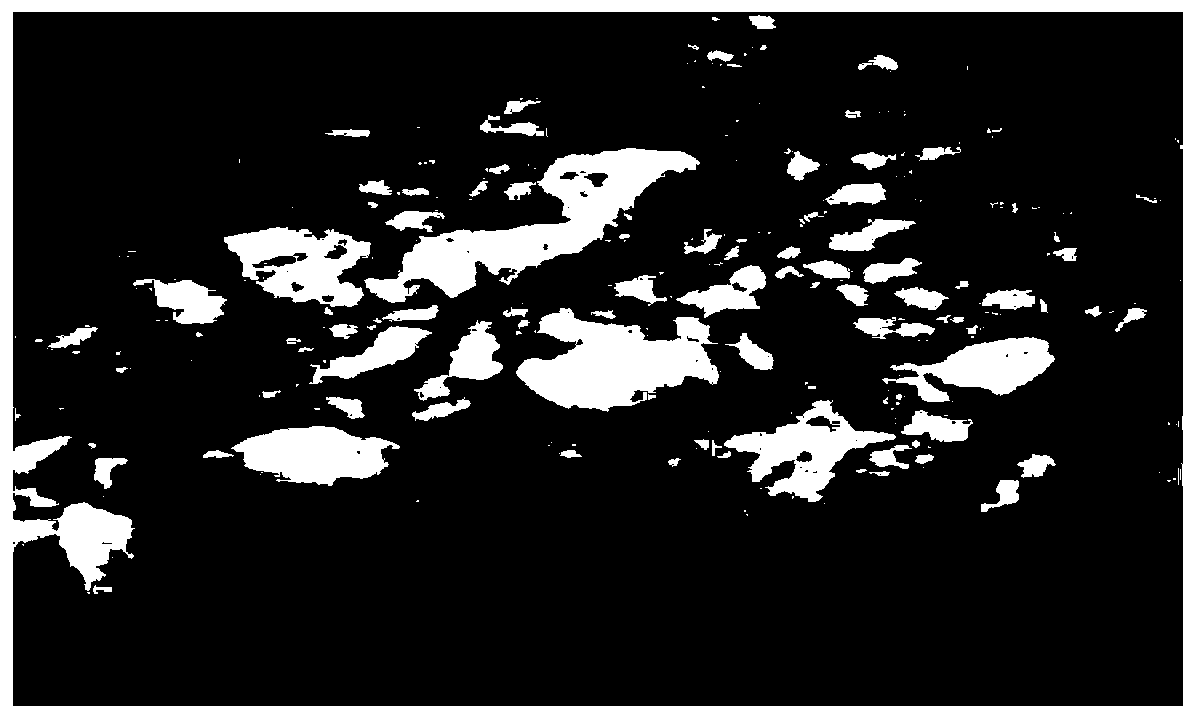

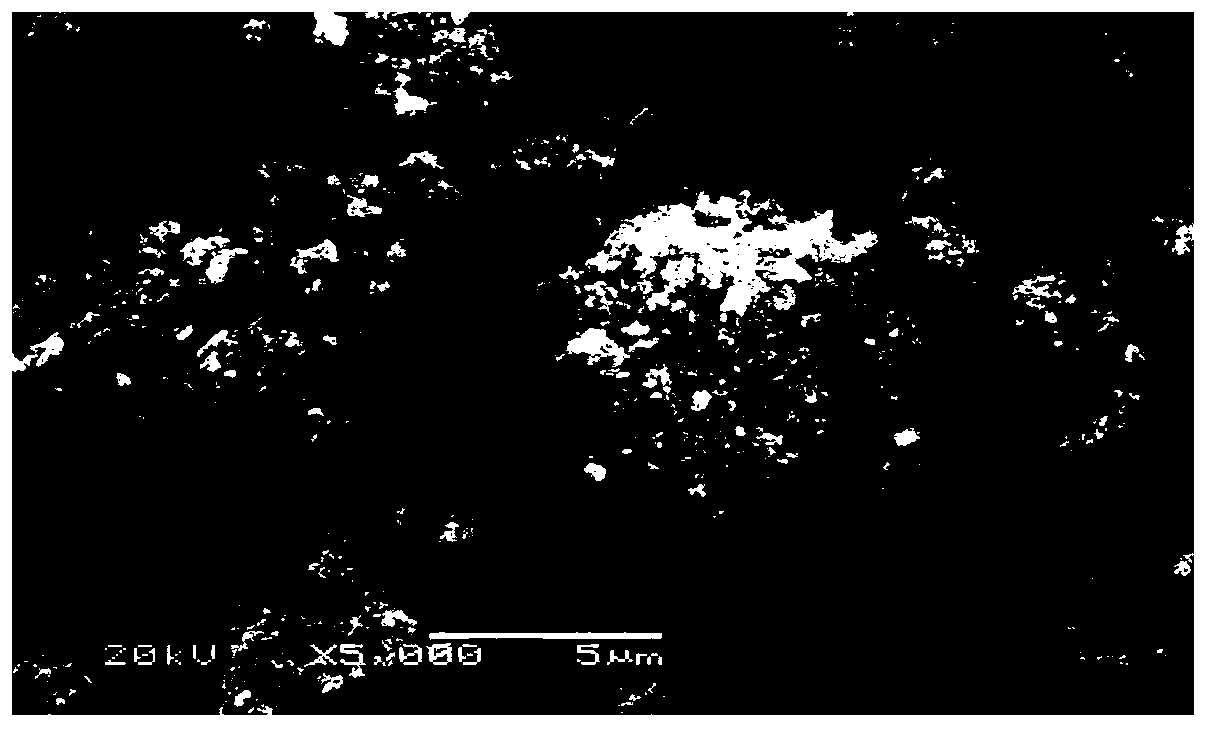

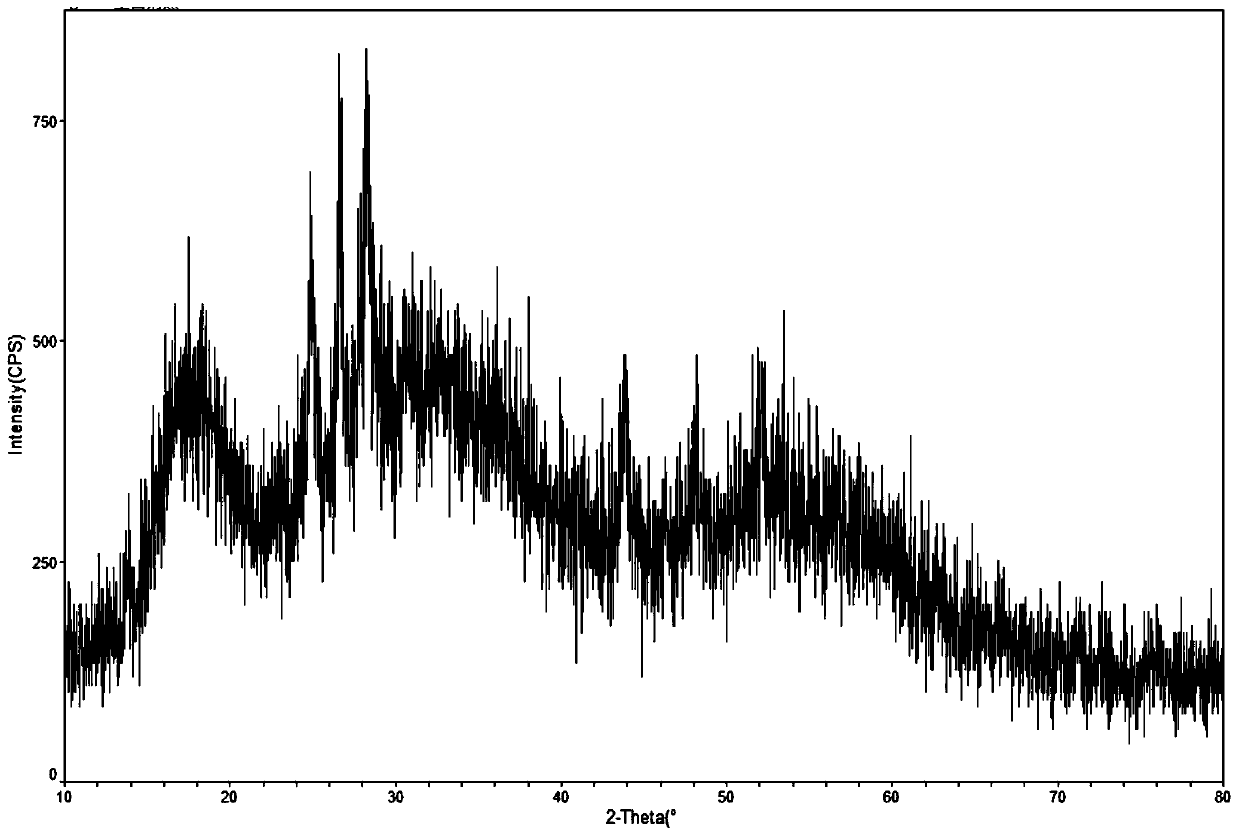

[0039] The arsenic sulfide slag from a copper smelter produced by sulfuric acid hydrogen sulfide treatment in a copper smelter has a moisture content of 70%, and the mass analysis of all elements shows that it mainly contains 25.7% of arsenic, 30.5% of sulfur, 0.71% of Cu, 0.17% of iron, and 0.12% of antimony %, lead 0.005%, cadmium 0.006%. Take 100g of its slag, add 600mL of water, the pH is 1.2, add 0.5g of ferrous sulfide, 0.1g of sodium thiosulfate, redox potential Eh=-0.31v. After stirring evenly, put the pretreated sample into a 1L high-temperature and high-pressure reactor with a filling rate of 70%. Turn on the stirring paddle, set the stirring rate to 1200 rpm, and adjust the heating rate to 1K / min. When the temperature reaches 180°C, keep it warm After 3 hours, the pressure was 0.45 MPa, and then cooling water was passed into the ring cooling pipe for cooling (the cooling rate was 50K / min) to lower the temperature to obtain the amorphous solid of arsenic sulfide. Th...

Embodiment 2

[0045] Take arsenic sulfide slag from a lead-zinc smelter produced by sulfuric acid sodium sulfide sulfidation treatment. The slag has been stockpiled in the enterprise for many years. 0.07%, zinc 0.13%, lead 0.012%, cadmium 0.001%. Take 200g of its slag, add 400g of water, the pH is 2.6, add 1g of ferrous sulfide, the redox potential Eh=-0.21v. After stirring evenly, put it into a 1L (filling rate of 60%) high-temperature and high-pressure reactor, turn on the stirring paddle, set the stirring rate to 100 rpm, adjust the heating rate to 5K / min, and keep it warm for 2 hours when the temperature reaches 200°C. After the temperature, the pressure is 0.52 MPa, and then the air is naturally cooled (cooling rate 2K / min). According to the experimental results, the arsenic sulfide amorphous solidified block obtained has arsenic leaching toxicity of 0.62 mg / L and block compressive strength of 11.6 MPa.

Embodiment 3

[0047] The difference from Example 1 is that arsenic sulfide slag produced from high-arsenic electrolytic waste liquid of another lead-zinc smelter is selected, and the mass content of the slag is 4.15% cadmium, 0.81% zinc, and 24% arsenic. The arsenic leaching toxicity obtained after the experimental treatment was 1.2mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com