Method for dry preparation of high-quality chlamys farreri adductor

A high-quality technology of Chlamys farreri, which is applied in the field of drying high-quality Chlamysalis scallops, can solve the problems of difficult long-term storage, low product yield, and easy corruption, and achieves hard-to-crack and scattered pillars, bright and transparent color, and The effect of sequential organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

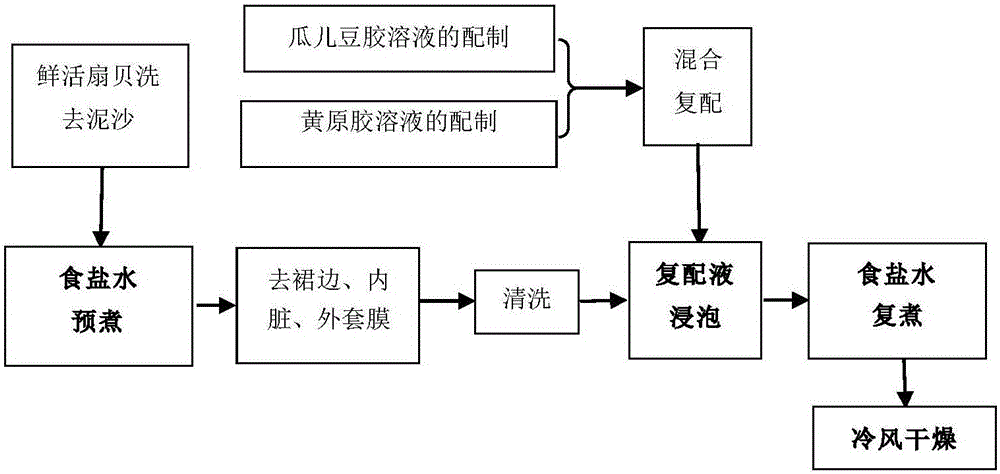

[0020] A method for drying high-quality clam scallop sticks is carried out according to the following steps:

[0021] (1) Pretreatment of scallops: wash off the surface sediment of fresh and live scallops, weigh 1000g, place them in 95°C water for 0.8 minutes, remove the shells, peel off the internal organs and skirts, and rinse the dirt on the surface of the scallops with water;

[0022] (2) Configuration of impregnation solution: Weigh 0.4g xanthan gum and 0.6g guar gum respectively, slowly add them to 200ml distilled water, put them into a water bath and heat at a constant temperature of 80°C to make xanthan gum and guar gum The glue is fully dissolved; after it is completely dissolved, mix the two glue solutions, stir and mix with a stirrer at room temperature for 30 minutes, stop stirring and let it stand for 30 minutes to make an impregnation solution for later use;

[0023] (3) Immersion: place the scallops in the soaking solution prepared in step (2) for 60 minutes;

...

Embodiment 2

[0028] A method for drying high-quality clam scallop sticks is carried out according to the following steps:

[0029] (1) Pretreatment of scallops: wash off the surface sediment of fresh and live scallops, weigh 1000g, place in 100°C water for 0.5min, remove the outer shell, then peel off the viscera and skirt, and rinse the dirt on the surface of the scallop with clean water;

[0030] (2) Configuration of the impregnating solution: Weigh 0.48g xanthan gum and 0.72g guar gum respectively, slowly add them to 200ml distilled water, put them into a water bath and heat at a constant temperature of 80°C to make the xanthan gum and guar gum The glue is fully dissolved; after it is completely dissolved, mix the two glue solutions, stir and mix with a stirrer at room temperature for 20 minutes, stop stirring and let it stand for 40 minutes to make an impregnating solution for later use;

[0031] (3) Immersion: place the scallops in the soaking solution prepared in step (2) for 50 minu...

Embodiment 3

[0051] A method for drying high-quality clam scallop sticks is carried out according to the following steps:

[0052] (1) Pretreatment of scallops: wash off the surface sediment of fresh and live scallops, weigh 1000g, place them in 95°C water for 0.8 minutes, remove the shells, peel off the internal organs and skirts, and rinse the dirt on the surface of the scallops with water;

[0053] (2) The configuration of the impregnation solution: Weigh 0.4g xanthan gum, 0.6g guar gum, and 0.8g cicada extract, slowly add them to 200ml distilled water, put them into a water bath and heat at a constant temperature of 80°C to make Xanthan gum and guar gum are fully dissolved; after they are completely dissolved, mix the two gum solutions, stir and mix with a stirrer at room temperature for 30 minutes, stop stirring and let stand for 30 minutes to make an impregnation solution for later use;

[0054] The method for extracting the cicada extract: dry the cicada and pulverize it; add 3 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com