High-efficiency transplanting machine with interchangeable seedling trays

The technology of transplanting machine and seedling tray is applied in the field of farming machinery, which can solve the problems of insufficient mechanized production level and low degree of mechanization, and achieve the effects of promoting intensification and scale, reducing labor intensity and large seedling load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

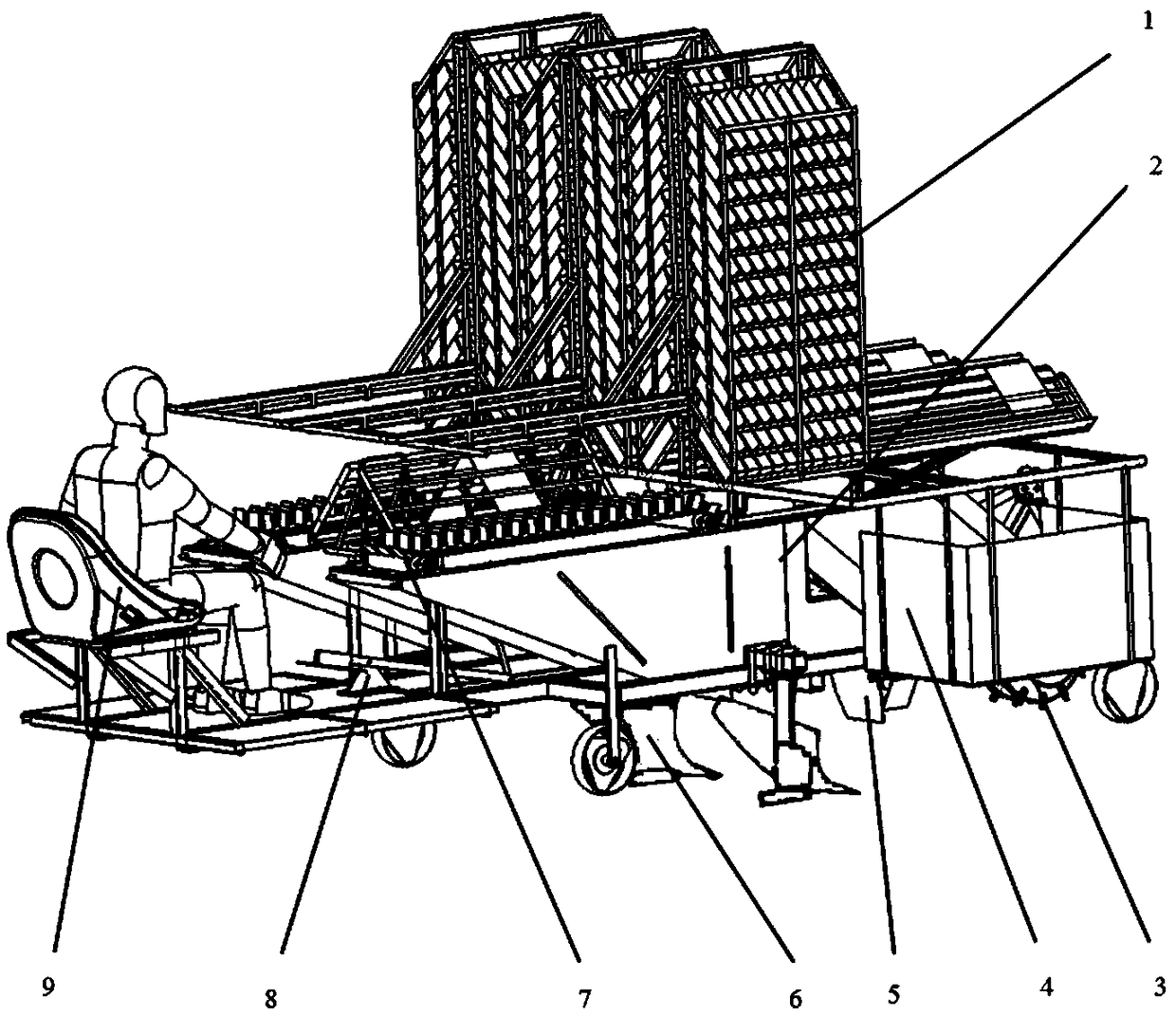

[0019] refer to figure 1 , the present invention is made of independent seedling tray 1, frame 2, transmission system 3, storage device 4, seedling raising board 5, ridging mechanism 6, conveyor belt 7, turning mechanism 8 and seat 9.

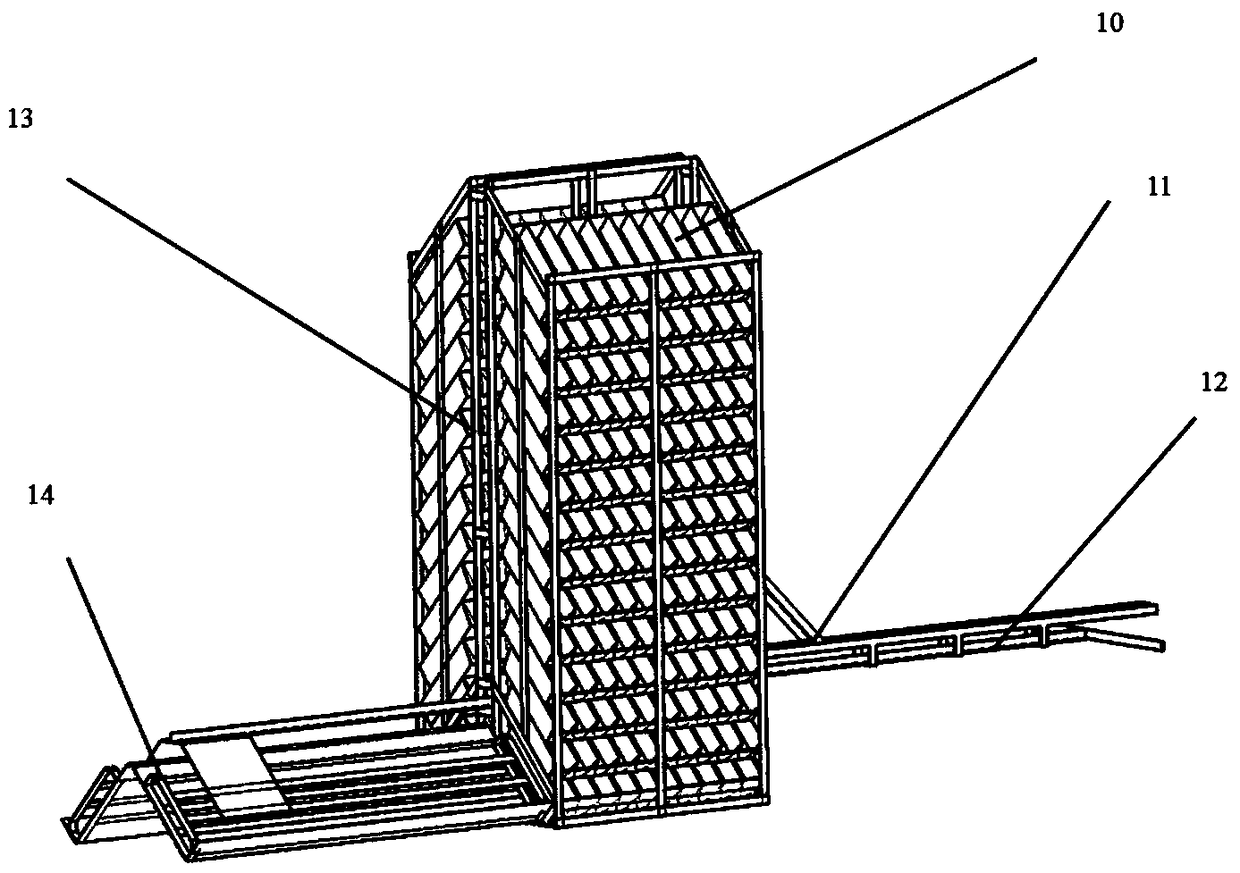

[0020] refer to figure 2 , the pull rod 12 of the independent seedling tray frame 1 is welded with the push tray bracket 14, and the slideway one 11 is welded with the seedling tray frame body 13; the seedling tray 10 is stacked obliquely in the seedling tray frame body, and the top of the seedling tray is supported by the push tray bracket; Connect with push plate bracket.

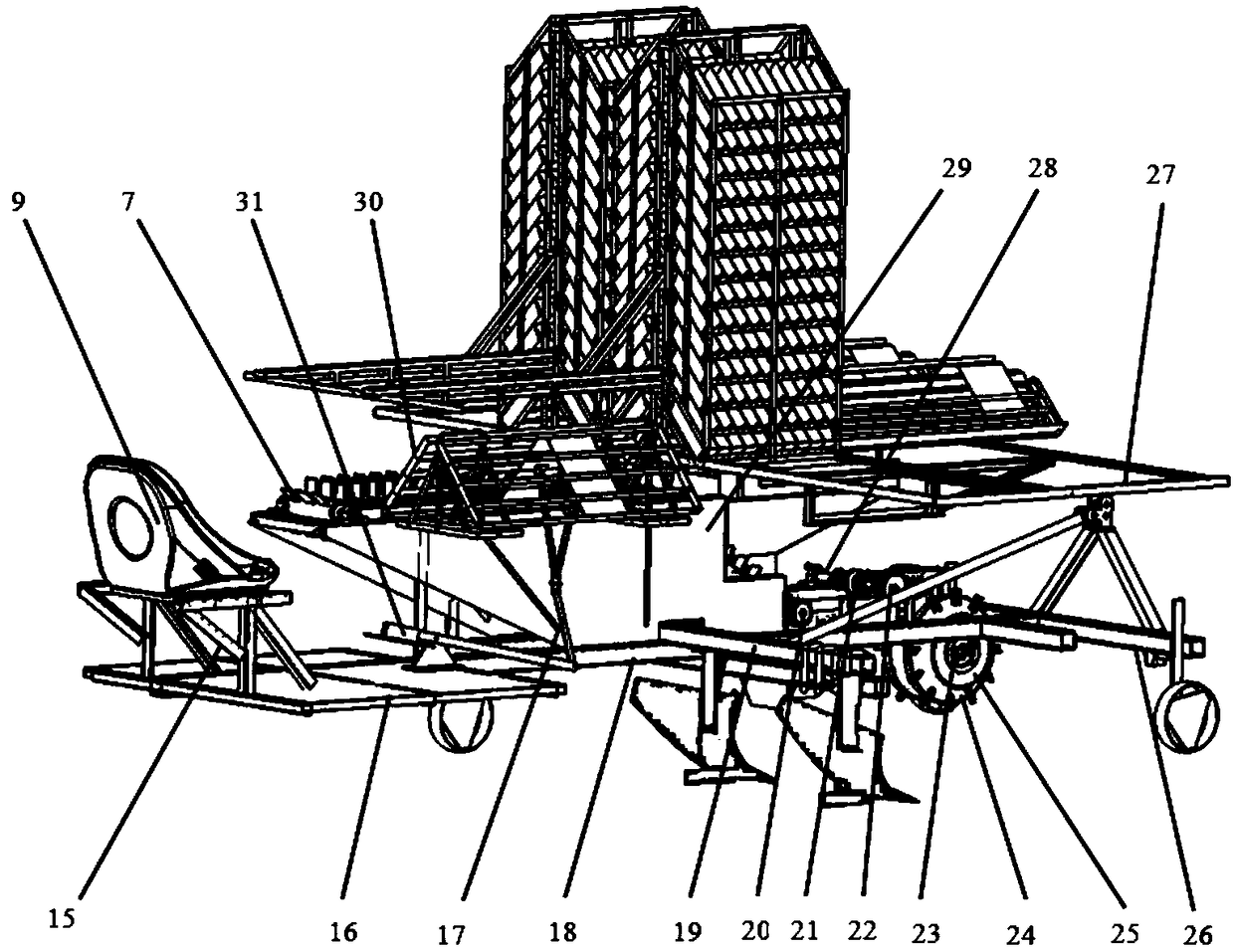

[0021] The three-point suspension bracket 32 is welded on the three-point suspension beam, and is respectively connected with the three-point suspension bracket 32 and the ridging plow beam 19 bolts through the diagonal stay rod 33. on the road support 27, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com