Pneumatic regulating valve used for mechanical manufacturing

A pneumatic regulating valve and mechanical manufacturing technology, which is applied in the field of mechanical parts manufacturing, can solve problems such as high noise, damage to the pneumatic regulating valve, and overall work imbalance, and achieve the effects of accurate flow characteristics, large working balance, and large allowable pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

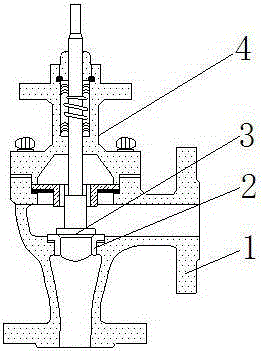

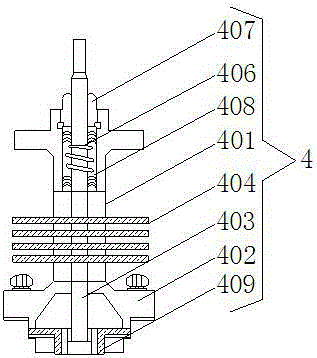

[0017] Embodiment one, refer to figure 2 : the spring pneumatic actuator 4 includes a valve tube 401 and a valve cover 402, the inside of the spring pneumatic actuator 4 is provided with a valve stem 403, and the valve stem 403 vertically runs through the valve tube 401 and the valve cover 402, the valve positioned above the valve cover 402 The inside of the pipe 401 is provided with a plurality of heat sinks 404 arranged at equal distances, and both ends of each heat sink 404 pass through the valve pipe 401 and extend to the outside of the valve pipe 401, and the valve stem 403 located above the heat sink 404 The surface is covered with a spring 406, and there is a gap between the spring 406 and the inner wall of the valve tube 401. A shaft seal 407 is arranged at the top of the gap, and a flexible graphite 408 is arranged in the gap. The valve stem 403 is in contact with the valve cover 402. The adjacent end is covered with a cylindrical guide sleeve 409 .

Embodiment 2

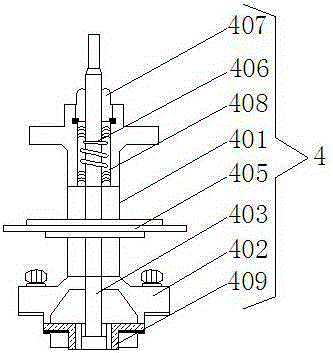

[0018] Embodiment two, refer to image 3 : The spring pneumatic actuator includes a valve tube 401 and a valve cover 402, the spring pneumatic actuator 4 is provided with a valve stem 403, and the valve stem 403 vertically runs through the valve tube 401 and the valve cover 402, and the valve located above the valve cover 402 The inside of the pipe 401 is provided with a plurality of heat shields 405, wherein the bottom heat shield 405 is the shortest, the middle heat shield 405 is the longest, and both ends of each heat shield 405 pass through the valve pipe 401 and extend to Outside the valve tube 401, a spring 406 is sheathed on the outer surface of the valve stem 403 above the heat shield 405, and there is a gap between the spring 406 and the inner wall of the valve tube 401, and a shaft seal 407 is arranged at the top of the gap , and flexible graphite 408 is arranged in the gap, and the end of the valve stem 403 close to the valve cover 402 is covered with a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com